HDgas. In Turin the final event

HDgas, in Turin, the curtain falls on the experience that over the last three years has radiographed the state of the art and the prospects of LNG. The full title of the project is ‘Heavy duty gas engines integrated into vehicles‘. HDGas. Iveco, Man, Volvo Technical evidence of liquefied natural gas affirmation in heavy transport. […]

HDgas, in Turin, the curtain falls on the experience that over the last three years has radiographed the state of the art and the prospects of LNG. The full title of the project is ‘Heavy duty gas engines integrated into vehicles‘.

Torino, 10,11/04/2018

HDGAS Final Event – FPT Industrial – CNH Industrial Village

HDGas. Iveco, Man, Volvo

Technical evidence of liquefied natural gas affirmation in heavy transport. Iveco, Man and Volvo are the heavy-duty truck players, FPT Industrial is the engine maker. AVL, the company who leads HDGas project, and Ricardo to weave the rows of the three types of power supply in comparison. The Politecnico di Milano is also involved.

VOLVO AND GAS ENGINE FOR TRUCKS? THE G13

What does HDGas mean?

What are the requirements of this European project?

It starts from a perhaps underestimated aspect, the technical and regulatory requirements of the LNG supply interfaces and the supply process for heavy-duty vehicles. The next step is storage. In other offspring, the LNG tanks, homologated with parameters for supply interfaces and filling processes. Exhaust after-treatment and low emission technologies (TRL6, Technology Readiness Level) is an unavoidable dimensional ballast for Euro VI. The obstacle is again on the table of designers of dual fuel and gas engines, to compress the methane volatile organic compounds and other climate-altering substances, below the Euro VI limits for heavy-duty vehicles.

Cursor 13 NG

“And the gas engine is…” (quoting Oscar awarding session) Cursor 13 NG.

The stoichiometric ratio is the core of the FPT setting. Let’s imagine the Iveco Stralis when changing gears. The lambda ratio supports the delivery of high torque via an automated gearbox. That is the premise. Contextualizing again Fpt’s contribution to HDGas, a combustion system, a direct fuel injection system, a corona ignition system, a variable valve timing and a hydraulic valve lash are rationalized. The favorited partners were Ricardo, who took on the installation of the lean-burn approach on the test bench, and Iveco. The stoichiometric version of FPT Industrial has made a mark, which means having respected the original performance target (2,200 Nm at 1,000 rpm and 370 kW at 1,900 rpm) and the reduction of 10 percent of CO2. Fuel consumption is even lower than the target of 200 g/kWh.

IVECO RUNS FROM TOKYO TO OSAKA

AVL, the project coordinator

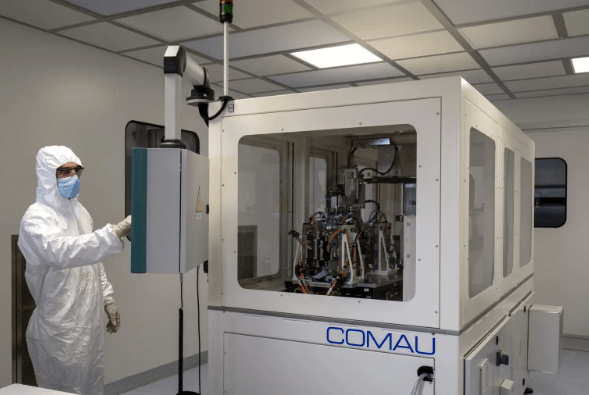

Hdgas was conceived and grew up under the watchful eye of AVL.

The Austrians mainly focused on the optimization of the combustion chamber. In view of their expertise, they also managed the installation in the test cell, with monitoring of the functioning of the test bench itself. Euro VI exhaust requirements compliance is a prerequisite. The focus has been on the production of CO2. Here, too, the mission is to cut by 10%. Autonomy, the deep desire of any hauler. AVL has identified a distance of 800 kilometers as the minimum requirement for reliability. Another goal concerns the overlapping of specific curves, especially torque, in comparison with diesel engines. (On the picture below Gernot Hasenbichler, AVL).

HDgas. One test for three concepts

Three HDgas engine technologies were on the ‘bench test’. A low-pressure direct injection spark ignited engine with a highly efficient EGR system. The second is a low-pressure port injected dual fuel engine. The third, a high-pressure gas direct injection diesel pilot ignition gas engine.

In terms of greenhouse gas emissions, research has shown the first two solutions, with a 10% cut, doubled by high-pressure injection system.

Partners

Other partners were Borgwarner, Bosch, Daimler, Dinex, SAG, Westport.