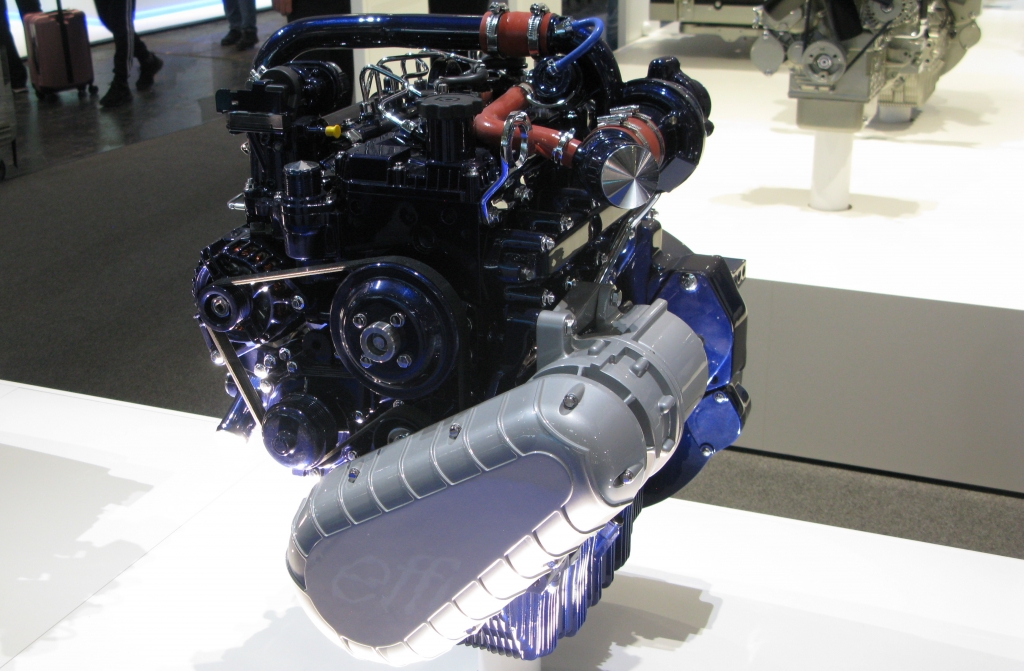

Interview with Ajay Prasher (Perkins), part 3

Here’s the third and last part of our long and articulated interview with Ajay Prasher, Perkins Product Marketing Manager. Here’s the first part of the article and here’s the second part. Mr Ajay Prasher, what are the benefits of the kinetic storage system? The kinetic hybrid system stores the recovered energy in the form of kinetic […]

Here’s the third and last part of our long and articulated interview with Ajay Prasher, Perkins Product Marketing Manager. Here’s the first part of the article and here’s the second part.

Mr Ajay Prasher, what are the benefits of the kinetic storage system?

The kinetic hybrid system stores the recovered energy in the form of kinetic energy. The nature of the kinetic system ensures that energy can be captured and stored quickly and released over a short period of time. For OEMs with un-predictable and variable speed duty cycles the kinetic hybrid system can be used to provide an additional 30 percent of engine power when required, helping OEMs to deliver considerable fuel savings and engine downsizing capabilities. Products in scope here would include crushers and wheeled loaders which have un-predictable and fluctuating duty cycles.

And what are the benefits of the hydraulic storage system?

The hydraulic hybrid stores recovered energy in the form of hydraulic pressure in an accumulator. The nature of the hydraulic storage system ensures that energy can be captured and stored quickly and released over a short period. For OEMs with un-predictable and variable speed duty cycles, the hydraulic hybrid can be used to provide an additional 30 percent of engine power when required, helping OEMs to deliver considerable fuel savings and engine downsizing capabilities. Products in scope here would include hydraulic excavators and wheeled loaders which have unpredictable and fluctuating duty cycles with a machine hydraulic system.

PERKINS ‘HYBRID SURPRISE’ AT BAUMA

How do you control the power output of the hydraulic hybrid system?

Perkins has developed a number of hydraulic hybrid systems and has been able to demonstrate significant improvements in fuel consumption, whilst optimising the transition between diesel-only power and hybrid power. Through machine duty cycle analysis, Perkins can assess the amount of energy recovery and boost required to ensure optimum sizing. An under-sized system will mean machines may not have enough power for hill climbs where an over-sized system will increase machine weight or reduce system efficiency.

What are the key features of the energy management system?

The energy management system is critical to maintain the long-term performance and reliability of the OEM machine. Perkins has been developing electric hybrid systems for over 10 years and understands the optimum window to ensure optimum performance and safe operation.

Do you plan to offer greater than 48V systems?

Perkins is considering higher voltage systems for hybrid applications to help OEMs where they may wish to support higher power machine systems.