Ricardo and the modular approach to powertrain innovation in off-highway

During a very interesting webinar held in Autumn, Ricardo shared the company’s point of view on powertrain innovation within the off-highway sector, talking a lot about electrification, hybridization or rather next-generation internal combustion engines, perhaps based on alternative fuels. According to the global company headquartered in Great Britain, all these options should be considered under […]

During a very interesting webinar held in Autumn, Ricardo shared the company’s point of view on powertrain innovation within the off-highway sector, talking a lot about electrification, hybridization or rather next-generation internal combustion engines, perhaps based on alternative fuels. According to the global company headquartered in Great Britain, all these options should be considered under a modular scheme.

Electrification to increase productivity

Talking about electrification, «the question is when, not if, regulations will be reinforced with financial penalities», said Andy Skipton-Carter, Head of Commercial Vehicle, Off-highway, Defense and Industrial Market Sector at Ricardo, pointing out that the main drivers for electrification are linked to CO2 reduction and improved air quality, but also to increased productivity. What is needed, however, according to Ricardo, is a modular and, one might say, customized approach, such as the one tailored to the characteristics of each individual type of machine.

Ricardo and the manifold requirements in the off-highway sector

Indeed, in the off-highway sector, each vehicle has different requirements in terms of power and mobility. These are supposed to guide those involved in the design of machines and components to the most suitable choice. For instance, a mini excavator has low average power requirement as well as low mobility requirement. A small tractor is a bit higher in terms of requirements. A crawler excavator has quite high average power requirement. A high-power tractor needs high power and has to be very mobile. Equipment with high average power is more suited to combustion engine for prime power source. On the other hand, applications with more stationary work or shorter shifts will favor high electrification.

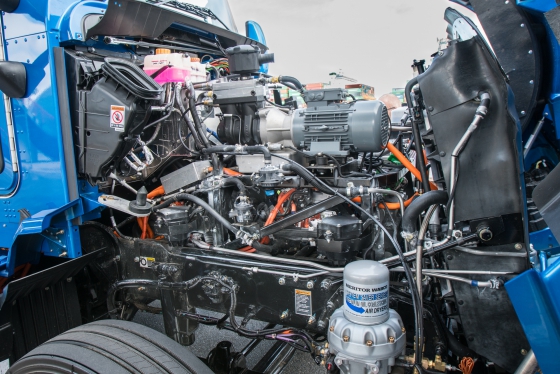

Full electric, hybridization or new-generation internal combustion engines, perhaps based on alternative fuels, are therefore options to be considered according to a modular scheme. Experience in different areas, availability of simulation tools for more effective design, test benches and the ability to analyze data are the ‘pluses’ that Ricardo may provide to manufacturers.

ICEs are still far from having had their day

Internal combustion engines are still far from having had their day according to Trevor Downes and Owain Davies, two other engineers from Ricardo. «Increases in technology for diesel powertrains, increase penetration of lower carbon fuels, such as natural gas, are two key factors looking to the future: internal combustion engines remain affordable, efficient, robust and capable of operating in virtually any condition. By increasingly prioritizing strategies for hydrogen and other alternative fuels, we will enable the phasing out of fossil fuels».