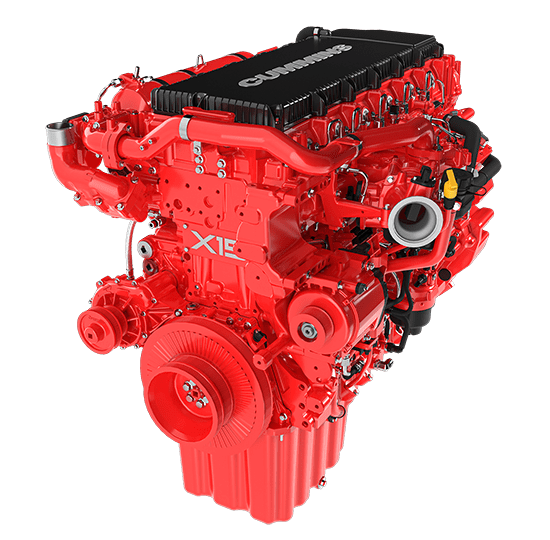

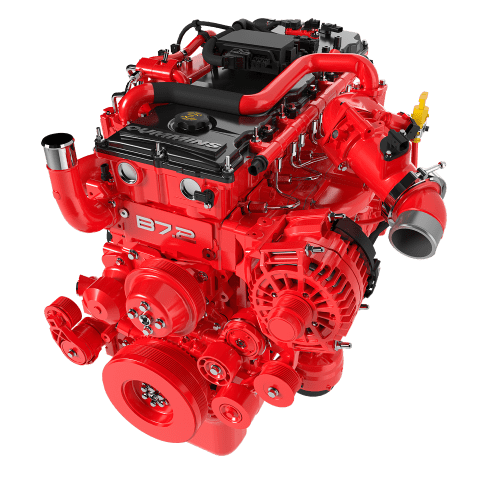

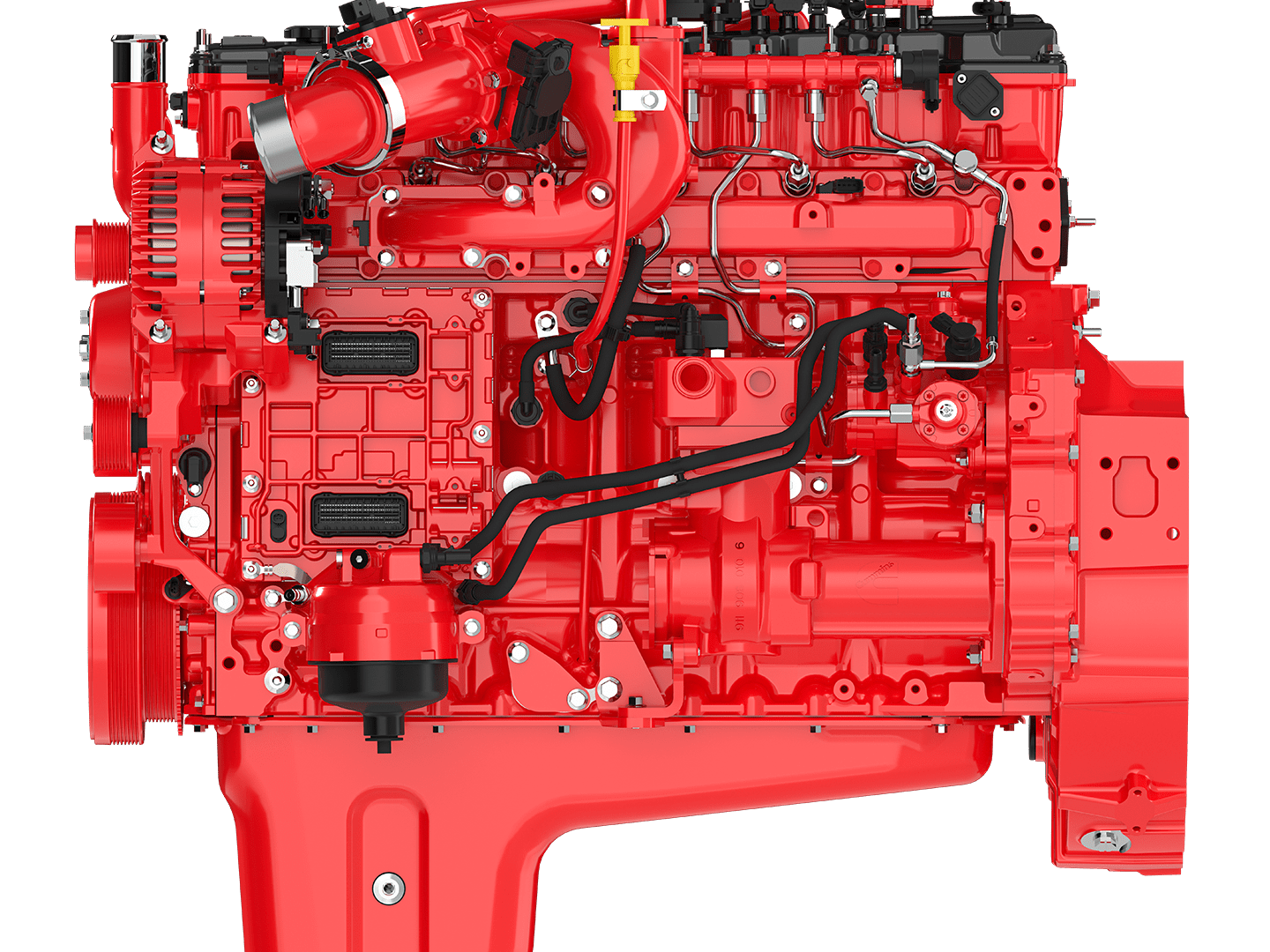

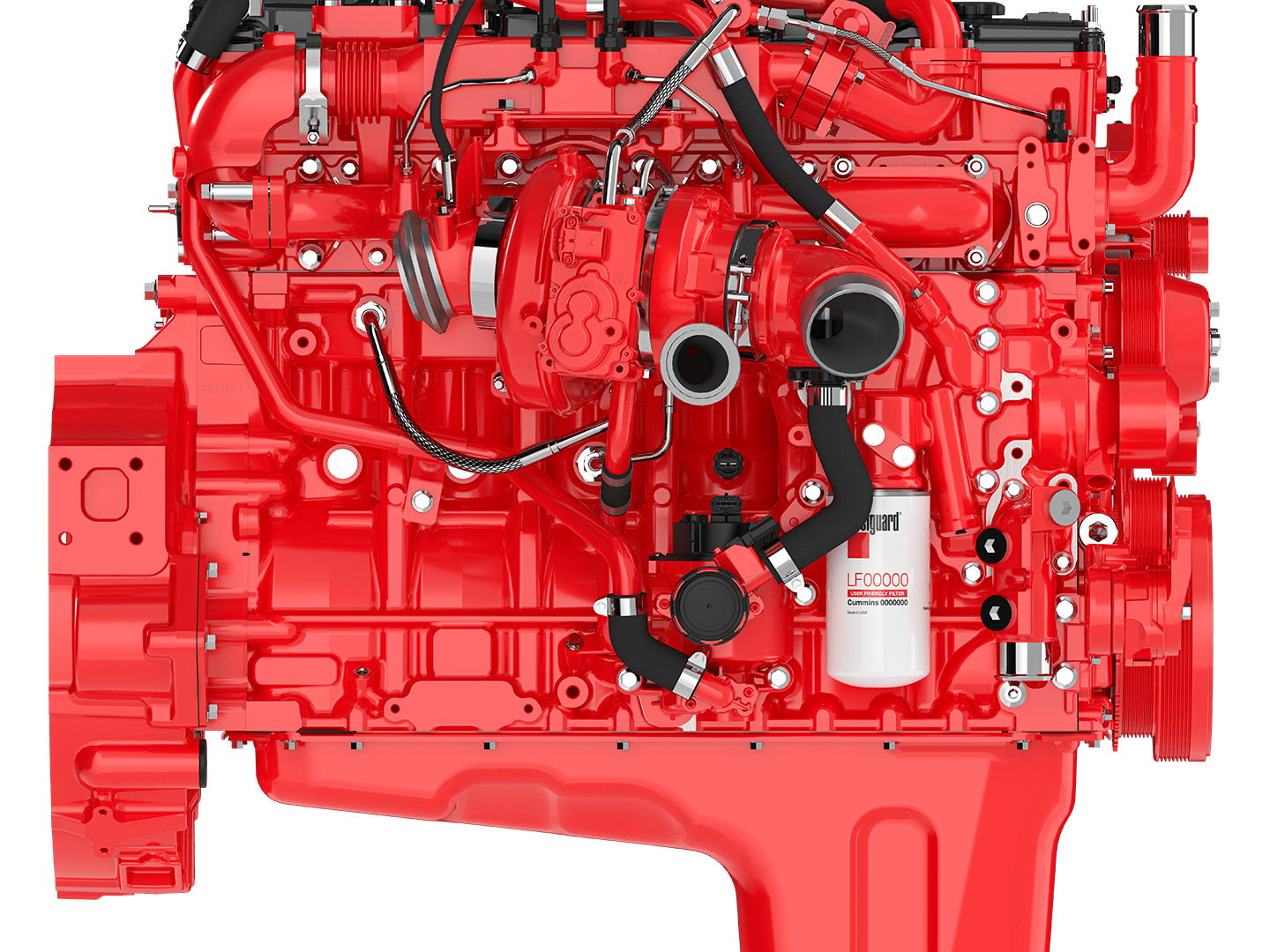

Cummins announces B7.2 diesel engine for medium-duty applications

The B7.2 diesel is the next engine in the B series Cummins HELM platform, following the B6.7 Octane engine, and will bring state-of-the-art technology and continue to serve a variety of medium-duty and vocational applications, including bus, pickup & delivery, utility trucks, refuse, towing, and more.

Cummins announced an update to the B-Series engine platform, unveiling the new Cummins B7.2 diesel engine at NTEA Work Truck Week in Indianapolis, IN.

“Our B engine is a legend known around the world. We are proud to unveil the newest version, the B7.2 diesel engine, right here in our backyard,” said Brett Merritt, Vice President and President – Engine Business. “The B7.2 brings the latest technology and advancements to one of our most proven platforms. Combined with the rest of our medium-duty lineup, our customers will have the right engine choices to fit their business needs, with the power and dependability they have come to expect from Cummins.”

The B7.2 diesel is the next engine in the B series Cummins HELM platform, following the B6.7 Octane engine, and will bring state-of-the-art technology and continue to serve a variety of medium-duty and vocational applications, including bus, pickup & delivery, utility trucks, refuse, towing, and more.

The new engine will feature a slightly higher displacement, increasing to 7.2L, and is designed to be a global platform which allows customers to ensure their vehicles are ready for what’s to come, without sacrificing performance or durability. A higher displacement also allows for a wider range of torque offerings, creating flexibility for different applications and duty cycles.

“Our customers have used the B-Series engine for more than 40 years and rely on it every day to meet their needs,” said Jose Samperio, Vice President North America On-Highway. “It was important that we offer the reliability and performance that they have come to expect, while also creating an engine that is built to last for the future.”

The B7.2 will improve unrestricted top-end performance ratings, providing 240 to 340 hp and 650 to 1,000 lb.-ft of torque.

Additionally, the new engine will be automatic engine shutdown and stop-start capable for improved greenhouse gas emissions and will offer a compression release engine brake and extended oil drain interval pan option.

It will also be equipped with Cummins’ full suite of digital technologies, which help enhance performance, maximize uptime and reduce total cost of ownership. The B7.2 provides digital connectivity and immediate access to a range of applications and capabilities through Acumen, Cummins’ smart computing hardware, and OEM first-fit solutions. Customers can utilize digital tools that enhance driver experience, including predictive capabilities (prognostics) and advanced over-the-air features. B7.2 is also Cummins Maintenance Monitor capable, reducing shop visits and minimizing cost of operation.

The B7.2 engine will be manufactured at Rocky Mount Engine Plant in North Carolina and will go into full production in North America starting in 2027.