Cummins and Tula cooperate for diesel efficiency and footprint: NOx emissions reduced by 74%

The system showed a 74 percent reduction in NOx and a 5 percent reduction in CO2 compared with today’s clean diesel technologies. In comparison with current engine technologies and modifications to the thermal management techniques, dDSF saved 20 percent in fuel

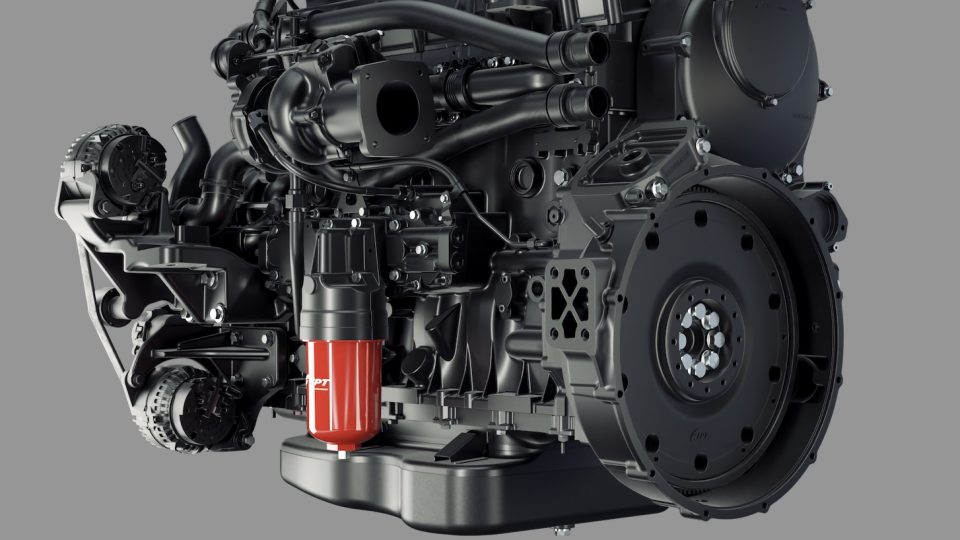

Cummins and Tula have recently announced the results of their collaborative study on the effectiveness of Tula’s diesel Dynamic Skip Fire (dDSF) in reducing NOx and CO2 emissions on a Cummins X15 HD Efficiency Series diesel engine.

According to the official statement, «low-load cycle performance was estimated with a well-calibrated powertrain simulation tool to accurately capture the low-load system operation and emissions. This system showed a 74 percent reduction in NOx and a 5 percent reduction in CO2 compared with today’s clean diesel technologies. In comparison with current engine technologies and modifications to the thermal management techniques, dDSF saved 20 percent in fuel, validating dDSF as a more fuel-efficient means of reducing NOx».

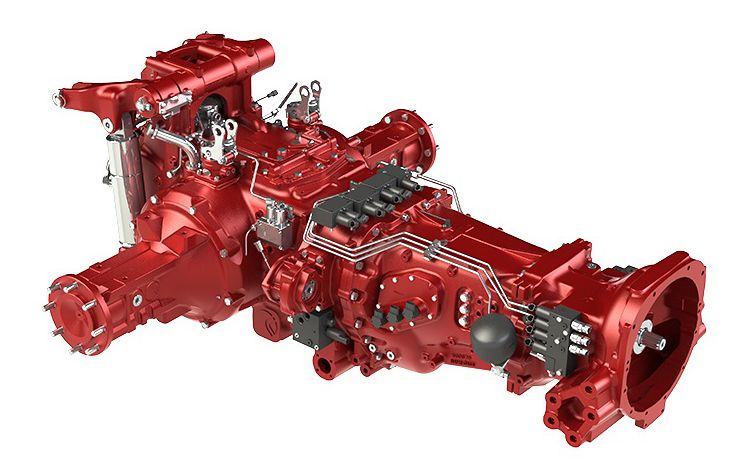

The Dynamic Skip Fire

Cummins and Tula demonstrated the positive dDSF results in a Class 8 truck powered by a Cummins X15 HD engine. The dDSF test results highlight a promising technical advancement for an industry seeking strategies to address future, more stringent NOx emissions regulations for diesel engines.

The Dynamic Skip Fire is an advanced cylinder deactivation control strategy that makes decisions for an engine’s cylinders on an individual basis to best meet torque demands while saving fuel and maintaining performance. Tula’s original DSF software has been shown to significantly reduce CO2 emissions in gasoline engines and has been in production since 2018 with more than one million vehicles on the road. dDSF is the Dynamic Skip Fire application for diesel engines.

Statements from Cummins and Tula

«Our mission at Cummins is to make people’s lives better by powering a more prosperous world, and we accomplish this through innovation», said Lisa Farrell, Director, Accelerated Technology Center for Cummins.

«Our dDSF is a powerful and unique technology that enables original equipment manufacturers to significantly reduce NOx emissions that contribute to smog while simultaneously reducing fuel consumption and greenhouse gas production. We appreciate the opportunity to work with Cummins to demonstrate the capability of our technology», added R. Scott Bailey, president and CEO of Tula Technology, a Silicon Valley-based company that provides innovative award-winning software controls to optimize propulsion efficiency and emissions across the mobility spectrum, including gasoline-powered, diesel, alternative fuel, hybrid, and electric vehicles.