DAF hybrid and electric trucks

DAF enters the hybrid and electric sector, aiming at city distribution and urban services, with the highest capacities

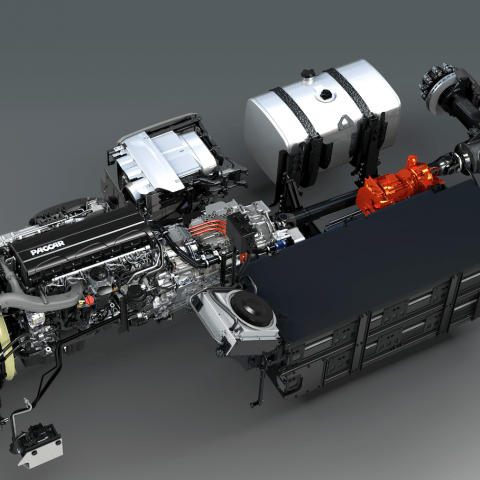

DAF decided to invest in hybrid and electric trucks technologies. Which they do, as is natural, with urban distribution and city service applications in mind (e.g. refuse collection) aiming straight to the highest capacities that fit into this kind of applications (HERE, the partnership with ZF and VDL).

DAF hybrid and electric trucks together with ZF

It is well known, after all, that city routes are short and low-speed, and hence ideal given that range is still every EV’s Achilles heel. On the other hand, the urban environment is also what suits best a powertrain whose gas and, notably, also noise emissions are equal to zero. DAF’S offer is particularly interesting not only for the 28-tonne potential GVW of the 3-axle CF, a fully-fledged heavy vehicle (and yet one that boasts high manoeuvrability thanks to a third steered axle) but also for the enticing truck and trailer combo with the same 28-tonne potential GVM. The weights we are talking here are, indeed, potential, to be measured against every country’s legal requirements. In both cases, however, these vehicles are ideal for round the clock supermarket distribution, as the truck’s (or tractor’s) battery pack can be (re) charged during loading and unloading operations.

100 – 150 kW to back batteries to 80% charge capacity

Indeed, 100/150 kW – a power range that is no doubt already available at every store – is well enough to bring batteries back to 80% charge capacity in half an hour, or a little more than that, thus securing the driving range that is needed to get back to the central depot – usually found in the suburbs – to get loaded with goods, as well as with electrons. Back and forth. And when the time comes to get fully charged, one hour and a half will be enough. Such difference in charging times confirms the time/charge level ratio as being non-linear; a detail to keep into account when planning when and where to get a recharge. While CF’s architecture is well known, there’s a difference with traditional versions in that this one is fitted with a 210kW engine and a 170kWh battery pack. Differently than on the models from the Volvo range, here there’s no gearbox and it’s up to the proverbial drive shaft-breaking torque of 2000 Nm that’s typical of electric motors to guarantee that driving is as smooth as required.

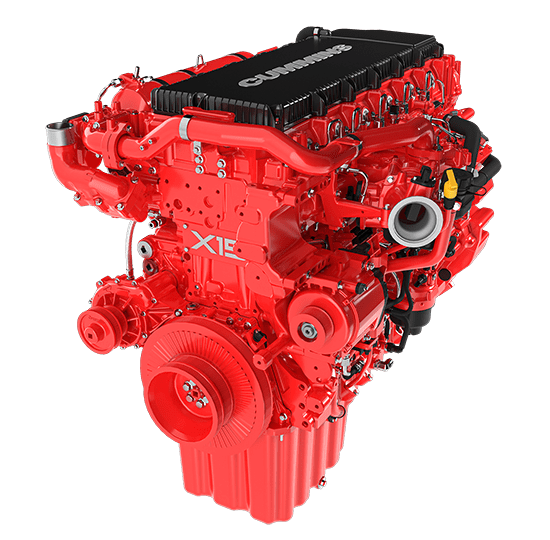

6.7 liters engine for the Diesel version

Power-wise, if we compared it to their diesel counterparts, the CF fitted with the 6.7 l M-X7 gets around 210kW, so you need to step up to the 10.8 l of the MX-11 to start with some ten kW more, going up to 330kW depending on rating. Whilst, then, they are similar in power, torque is what truly marks the difference: with 2000Nm, we’re getting 50 to 100% more as compared to the MX-7 with the same power level, and only the XM-11 with higher ratings manages to go slightly above that. What’s more, one can benefit from the extraordinary torque curve that’s typical of electric motors: an awful lot of torque immediately available that stays as high as desired.

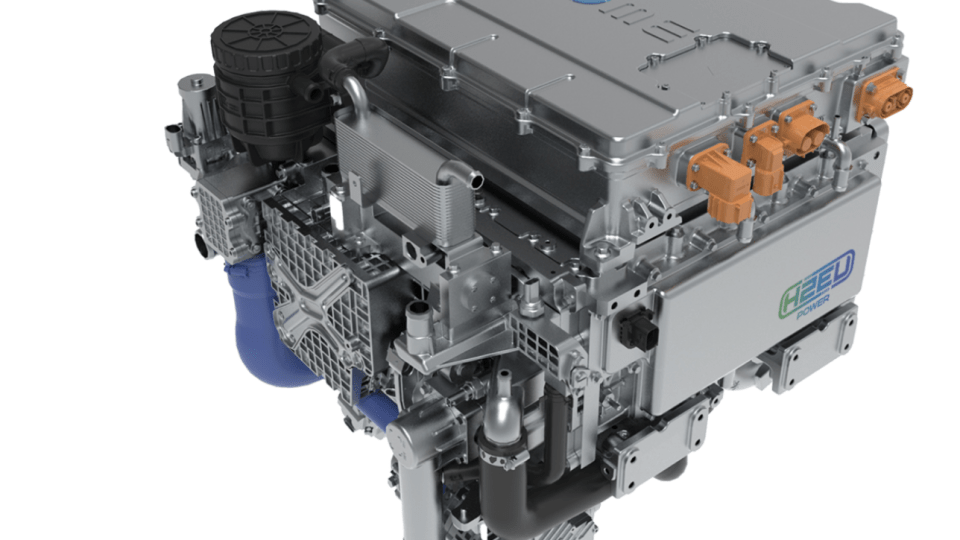

Going back to the hardware, the whole powertrain was named VDL E-Power and it stems from cooperation with Dutch company VDL taking charge of the entire electric section, from batteries to the motor, all the way through to the BMS, down to the very quick charging stations.

FIND OUT THE COMPLETE ARTICLE, PUBLISHED IN THE MAY ISSUE OF POWERTRAIN MAGAZINE