A top-notch driveline: the VDL Futura bus relies on DAF and ZF

Let’s talk about buses and mention a driving impression recently published by our colleagues from AUTOBUS magazine (here’s the link to the international magazine Sustainable Bus). The VDL Futura Fhd2-129 bus stands out for its driveline thanks to the collaboration with two giants such as DAF and ZF. As usual, we focus our attention on […]

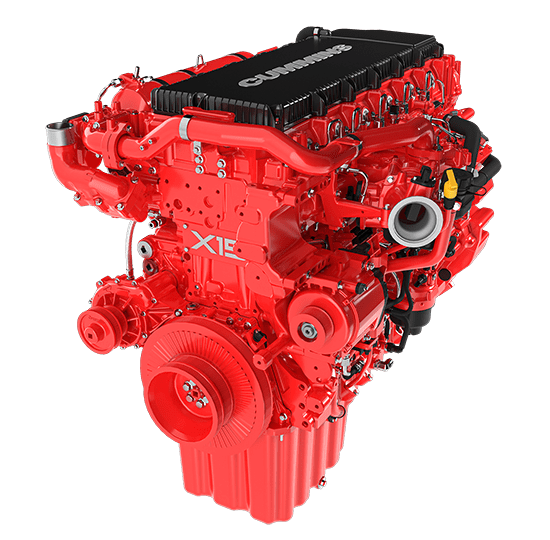

Let’s talk about buses and mention a driving impression recently published by our colleagues from AUTOBUS magazine (here’s the link to the international magazine Sustainable Bus). The VDL Futura Fhd2-129 bus stands out for its driveline thanks to the collaboration with two giants such as DAF and ZF. As usual, we focus our attention on the driveline. Starting with the engine, a 450 hp (330 kW) DAF Mx11 six-cylinder engine whose engine block, cooling system, air intake, bearings and pistons have been completely redesigned.

The compression ratio is also increased while the turbocharger is more efficient. The combustion process has also been improved, allowing maximum torque to be reached at just 900 rpm. All this, in tandem with ZF’s Traxon, results into a reduction in engine rpm of up to 100 rpm at 100 kilometres per hour.

The VDL driveline: safety guaranteed thanks to the braking system

The driveline deals indeed with the matter of safety. The new transmission offers high braking performance thanks to the combination of the ZF Intarder with the DAF engine brake (DEB). This makes it possible to reduce speed without using the service brake, which is advantageous in terms of reduced maintenance costs. With the new generation of engines, the DEB has become even more powerful. A further advantage is that the DEB gives its contribution to accelerate the ZF Traxon gear control by reducing the engine speed more quickly.

Around 100 kilos of weight saving

The new layout of the engine compartment, which involves moving the radiators from the right to the left side, has resulted in a considerable weight saving of 100 kilos. The goal of this new layout is to further optimise the accessibility of the engine compartment in order to allow more effective maintenance and repair work. Besides, ZF’s Traxon is also 20 kilos lighter than its predecessor. The entire weight saving has been achieved behind the rear axle.