FPT Industrial at the Dakar 2025 secures nine out of ten top positions

FPT Industrial is once again on the podium at the Dakar Rally: the 47th edition of the world’s most challenging rally raid, the Dakar 2025, has seen another remarkable achievement added to the brand’s legacy.

FPT Industrial is once again on the podium at the Dakar Rally: the 47th edition of the world’s most challenging rally raid, the Dakar 2025, has seen another remarkable achievement added to the brand’s legacy.

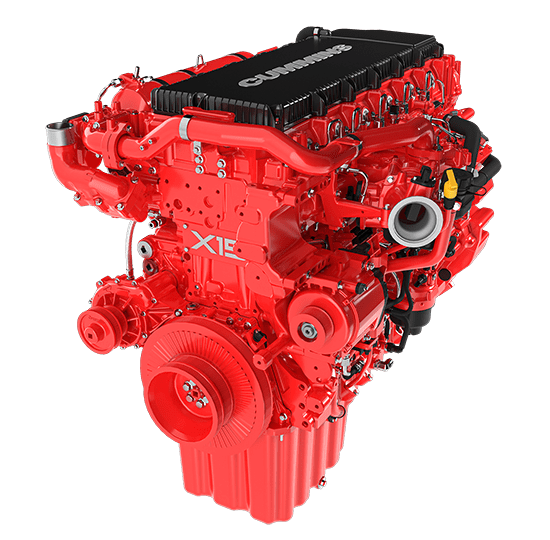

Indeed, IVECO vehicles – powered by FPT Industrial’s engines – swept the podium and secured nine out of ten of the top final places in the truck standings. As Exclusive Technical Partner, the brand supported de Rooy FPT teams, led by the drivers Aleš Loprais, Vaidotas Žala and Anja Van Loon. Loprais, from InstaTrade Loprais Team de Rooy FPT, took 3rd place with the well-known IVECO Powerstar model 2024/2025 equipped with FPT Industrial’s Cursor 13 engines, designed to deliver unmatched power, efficiency, reliability, and sustainability in the toughest conditions. Vaidotas Žala, the new entry to Skuba Team de Rooy FPT, and Anja Van Loon (Fried Van de Laar Racing Team de Rooy FPT), who had already experienced the Dakar Rally in 2024 with a first-class performance, conquered the dunes of the stunning Saudi Arabian landscapes with impressive performances across multiple stages, including six podium finishes for Žala and a fourth-place finish for Van Loon. These two drivers finished the rally fifth and eighth respectively, recording their best-ever results in the competition.

This year’s edition – confirmed by the organizers as one of the most challenging ever – featured twelve stages covering a total of 8,000 kilometers from Bisha to Shubaytah, including more than 5,000 kilometers of specials. For eight out of the twelve stages, Aleš Loprais finished in the top three positions, winning five of them. This outstanding result was achieved thanks to an exceptionally high-performance and reliable vehicle and engine, which never let the team down throughout the rally.

Driving through one dune after another, the Dakar route highlighted all the qualities of the FPT Industrial Cursor 13 engines, designed to supply the highest levels of power, efficiency, reliability, and sustainability in the toughest applications. Even for everyday challenges, they represent the best solution for long-distance and heavy-duty trucks of over 16 tonnes Gross Vehicle Weight (GVW), thanks to best-in-class performance and transient response with low fuel consumption. FPT Industrial’s patented HI-eSCR technology – an EGR-free solution – ensures low Total Cost of Ownership (TCO), thanks also to the DPF with passive regeneration and best-in-class oil change intervals of up to 150,000 km. DPF cleaning at up to 600,000 km and reduced oil consumption provide significant advantages in terms of uptime and reduced costs.