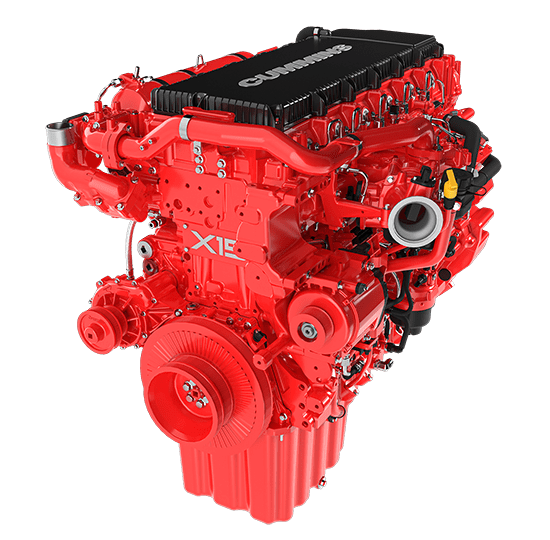

MAN “ignited” the D30 Diesel engine

Some features regarding MAN D30 13L Diesel engine: 250 million euros invested in Germany – production with 160 employees in Nuremberg. D30 engine with improved fuel efficiency jointly developed in the TRATON GROUP

With the D30, MAN remains loyal to its tradition and raises the bar for internal combustion engine technology. However, I would like to hold the horses. We quote the exact words of the press release. ”It will be the last completely newly developed diesel commercial vehicle engine at MAN – there are no plans for a successor generation.”

MAN D30, the Last Knight

In short, from the cradle of the Diesel Cycle comes news with a bitter-sweet taste. On the one hand, it raises the table on energy efficiency, starting from its most well-established expression. That applied to the alchemy of the combustion chamber, with the appropriate upstream and downstream adjustments. On the other hand, the company states that it will be the last intervention on an ICE platform. It is significant that in spring the battery series production in the same plant in Nuremberg will be opened in parallel. We assume this means one thing: there will be no more blank-sheet engines and upgrades will be made to sensitive components, fuels and hybrid units. It is the largest standard engine in the portfolio, which is mounted in the 40-tonne MAN TGX and TGS semitrailer tractors. We assume that, like its forerunners, the MAN D30 will also find application on yachts and, most likely, in off-highway and power generation. Production capacity is estimated at around 50,000 units per year. The Man D30, available in six power levels from 380 to 560 hp (2,100 to 2,800 Nm), will progressively replace the D26 and D15 series, 6-cylinder 12.4L and 9 L. Focusing on MAN’s core application, the truck, in combination with the PowerLion transmission, claims an average fuel saving of 5% compared to a TGX with the previous generation of driveline

Listening to the MAN CEO

MAN CEO Alexander Vlaskamp commented on the opening of the manufacturing line in Nuremberg: “By 2030, every second vehicle we deliver to our customers is to have an emission-free drive. However, this also means that we will still need very efficient combustion engines for a long time on the road to the transformation to electromobility. In Nuremberg, we are therefore investing in both technologies, making the location future-proof and putting it on two strong legs. This is how we secure employment. And in Bavaria, we can count on the support of the Bavarian state government so that we can continue on this course.”