MAN Truck & Bus, green light to the site for the production of the diesel engine

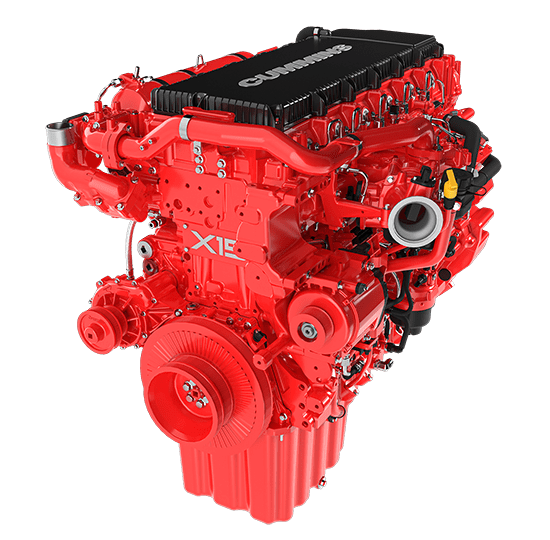

With an investment of 170 million euros, the new 23,000 m2 building is one of the largest projects within the MAN site in Nuremberg. The new 13-litre diesel engine will be developed for all Traton Group brands.

With an investment of 170 million euros, the new 23,000 m2 building is one of the largest projects within the MAN site in Nuremberg: the new 13-litre diesel engine will be developed for all Traton Group brands.

With the inauguration ceremony of the area intended for the production of the new diesel engine, the Nuremberg plant added another milestone to its transformation. The event, which was attended, among others, by the mayor of Nuremberg Marcus König, the CEO of MAN Truck & Bus Alexander Vlaskamp and the site manager Ulrich Zimmer, concluded the 15-month construction phase.

MAN, the new Nuremberg diesel factory

With an investment of approximately 170 million euros, the new building is one of the largest projects within the MAN site in Nuremberg: more than 160 highly skilled jobs will be created on approximately 23,000 m2.

The employees, divided into three shifts, will produce the main components of the new 13-litre diesel unit of the Traton Group which will be used jointly by all brands. The structure and the production line are designed according to the most recent energy efficiency systems without forgetting factors such as ergonomics and accessibility which will make the common spaces an attractive and sustainable work environment.

From 2024, the new 13-litre engine of the Traton Group will be produced in the Nuremberg plant right alongside the production of batteries that will power the new MAN electric trucks. In the course of this technological transformation, both conventional and conventional propulsion systems in the future electrified will be side by side on the Munich production line: thus Nuremberg will supply vital components for both types of propulsion.

The new diesel engine, developed in close cooperation between the brands of the Group, bridges the gap between the internal combustion engine and the electrified transmissions of the future. With its significantly lower fuel consumption than the previous engine, the new unit will set new standards.