Scania and Regroup to launch autonomous mining truck fleet

“This is a historic moment for both Scania and the mining industry,” says Manfred Streit, Managing Director of Scania Australia. “Partnering with Regroup to launch the first global order of our autonomous trucks in Australia is a great achievement. This project demonstrates the potential of autonomous vehicles in one of the world’s most demanding environments.”

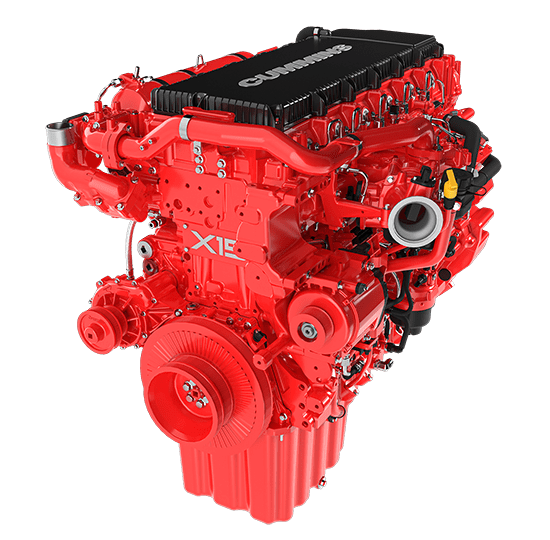

Scania is partnering with Australian mining services provider Regroup to launch its first fleet of autonomous in-pit mining trucks in commercial operations. These autonomous rigid G 560 8×4 tippers will begin operations at Element 25’s Butcherbird Mine in Western Australia’s Pilbara region by late 2025.

Read also: MAN and Scania work with U.S.-based Plus on autonomous truck development

This fleet of 11 autonomous trucks will transport manganese ore, marking a milestone for Scania and Regroup, and for the global mining industry. The announcement follows the recent opening of Scania’s order book for commercially available autonomous trucks. “With this fleet order, we bring to commercial reality the concept of an autonomous fleet working at scale in demanding real-world conditions. We anticipate the Regroup fleet deployment will be the first of many, as operators around the world see the safety, productivity and ease-of-use benefits of Scania’s technology,” says Peter Hafmar, Head of Autonomous Solutions, Scania.

Scania Australia has collaborated with local mining industry partners to refine its autonomous truck programme over the past years. The upcoming fleet represents a breakthrough, combining advanced technology with operational expertise to enhance efficiency and reduce the environmental footprint of mining operations.

“This is a historic moment for both Scania and the mining industry,” says Manfred Streit, Managing Director of Scania Australia. “Partnering with Regroup to launch the first global order of our autonomous trucks in Australia is a great achievement. This project demonstrates the potential of autonomous vehicles in one of the world’s most demanding environments.”

Regroup’s vision for a sustainable future

Regroup, a civil, mining, and bulk haulage contractor, views this partnership as a crucial step toward a future of autonomous, electric mining fleets. The introduction of autonomous trucks is the first phase of this transformation.

“We’re aligned with Scania in our commitment to innovation and sustainability,” says Michael Still, Managing Director of Regroup. “This project will revolutionise mining operations by integrating autonomous solutions, eventually leading to fully electric vehicles.” In addition to the autonomous fleet, Regroup has also ordered a battery-electric Scania 8×4 truck to be used as a water cart at the Butcherbird site, reinforcing its goal of reducing environmental impact. Although the initial fleet will operate on diesel engines, both companies are committed to an electric future.