Škoda makes engines more efficient through an innovative plasma coating

Škoda Auto has implemented a new processing line for plasma coating by adding an assembly line with two special fixtures for plasma coating at its main plant. Such an innovative concept allows conventional cylinder liners to be replaced with a powder coating that measures just 150 μm (0.15 mm), resulting in a significant reduction of […]

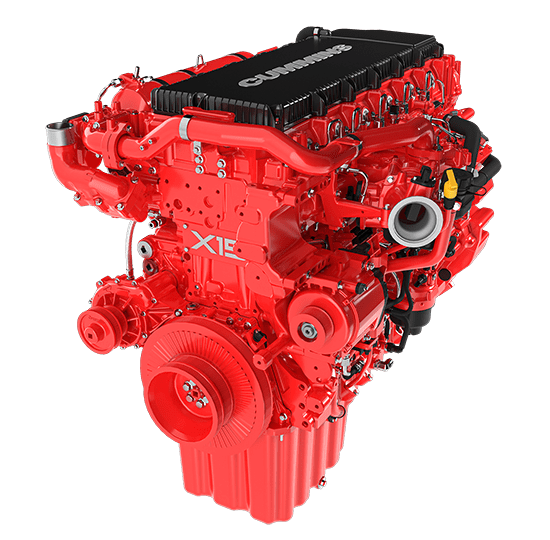

Škoda Auto has implemented a new processing line for plasma coating by adding an assembly line with two special fixtures for plasma coating at its main plant. Such an innovative concept allows conventional cylinder liners to be replaced with a powder coating that measures just 150 μm (0.15 mm), resulting in a significant reduction of internal friction. As a matter of fact, the 1.0 TSI EVO petrol engines will be even more efficient and boast even lower emissions.

Škoda has invested around 29 million euro in preparing and converting its Mladá Boleslav-based headquarters; overall, the Czech carmaker has spent 69.1 million euro on modernising engine production. Those are impressive figures also for the automotive sector.

The innovative Škoda plasma coating: the production process

During the production process, the cylinders are first bored on the machining line. A 1,500-watt laser then abrades the cylinder bores to ensure that the plasma layer will optimally adhere to the surface. This involves the laser beam creating ten grooves per millimetre, each measuring an average depth of 40 μm. This production step takes place in a controlled atmosphere filled with nitrogen to keep the laser’s optics free from contamination and to ensure the necessary level of accuracy.

The plasma-coated engines produced by Škoda at Mladá Boleslav

«The technically highly innovative plasma coating makes our EA211 TSI EVO engines even more efficient. What’s more, this type of coating also allows heat to be more evenly distributed within the cylinders and helps it to dissipate more efficiently, thus optimising the thermal load. We produce the plasma-coated engines at Mladá Boleslav in three shifts and are installing them in the Fabia, Scala, Octavia, Kamiq and Karoq», said Christian Bleiel, Head of Component Production at Škoda Auto.