ZF technology enables Tevva to develop more efficient regenerative braking system

ZF’s EBS has been adapted by Tevva engineers to work with the British electric truck maker’s regenerative braking. The system thus recovers up to 4 times more energy than a traditional pneumatic braking system

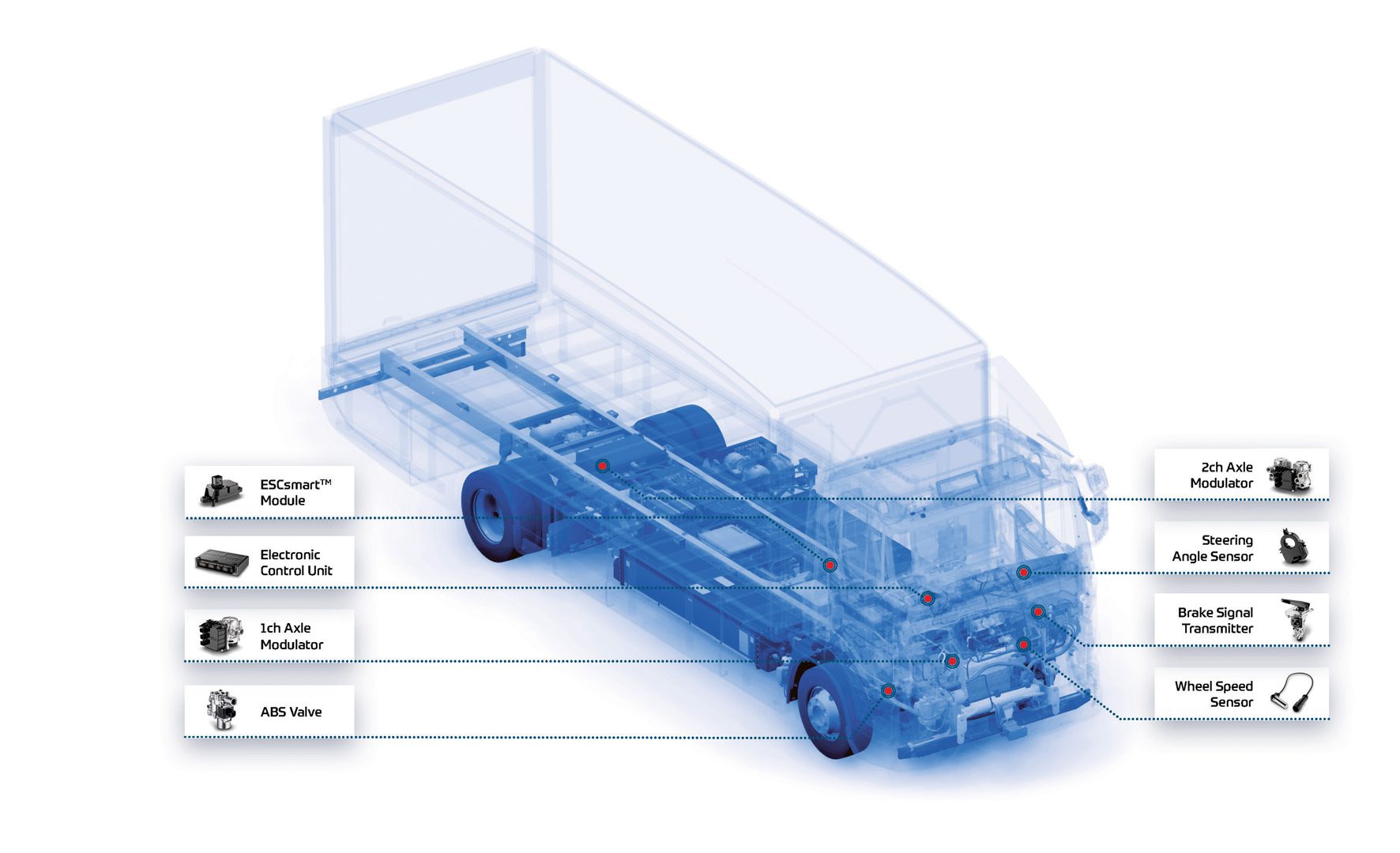

As a preferred supplier and development partner, ZF successfully worked with British electric vehicle manufacturer Tevva on the development of the regenerative braking system on its 7.5t battery-electric truck. Part of this, involved ZF closely collaborating with Tevva engineers to integrate its Electronic Brake System (EBS) for use in zero-emission Tevva electric trucks.

ZF’s Heiko Eggers, Head of EMEA Application Engineering for Braking and ADAS in the Division Commercial Vehicle Solutions, said: “Our broad product portfolio and systems competence, including ZF’s standardised Electronic Braking System, enables faster time-to-market for new, innovative market players such as Tevva. Their commitment and agile engineering expertise allowed us to meet our stringent safety requirements and complete our project. We look forward to seeing the first Tevva trucks on the road.”

Tevva’s Uzair Jilani, Lead Engineer, Drive and Brake Systems, said: “We have worked hard to secure a ringing endorsement from arguably one of the world’s most significant Tier 1 suppliers. Working with ZF is a crucial step in the momentum we are building as a truck manufacturer. The system has been adapted for use with our regenerative system; when the brake pedal is pushed, most of the ‘braking’ is handled by regenerative, meaning that the drive system slows the vehicle down. The conventional braking system is still needed to bring the truck to a complete stop, but this double layer of safety is an excellent aid to more efficient driving. It also means that the hardware undergoes less strain to extend the braking system’s life in the long run.”

Tevva’s engineers successfully met a range of stringent testing criteria for the company’s truck, working on fine-tuning the electric truck’s vehicle control unit (VCU) and enhancing compatibility with the EBS. The result is a system that recuperates up to four times more energy than a conventional compressed air brake system, optimising the range of the Tevva truck. The implementation of EBS allows for a safe incorporation of regenerative braking up to 180 kW, whereas the traditional air brake system had limited passive regen to around 40 kW due to safety considerations. Testing of the adapted system, which took place at the ZF test track in Jeversen, Germany, involved a variety of conditions, gradients, and surface types.

Technological advancements allow a modern EBS system to control the blending of friction braking with the e-motor, reducing brake wear and tear. The system transfers the driver’s deceleration request electronically to all braking system components to shorten response time, balance brake forces and provide ease of braking and efficient brake management.

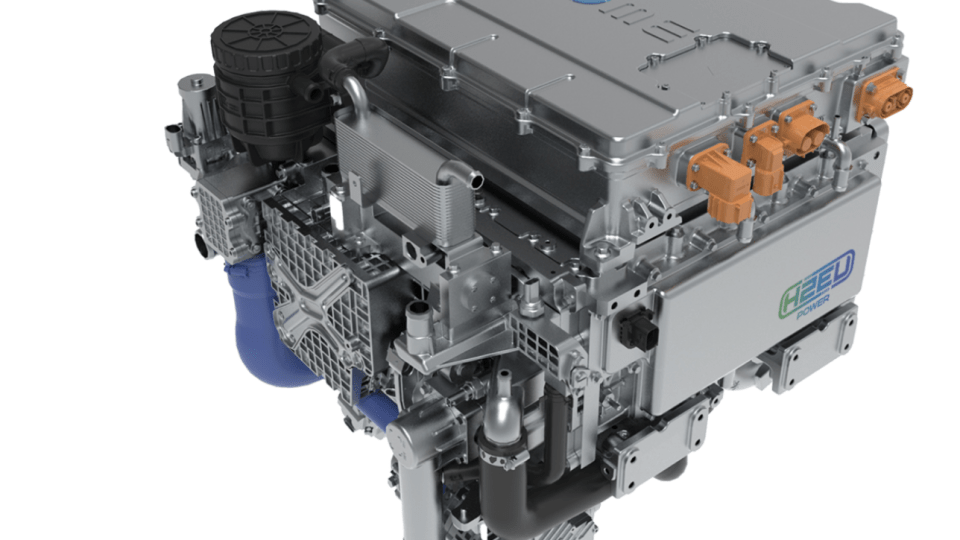

Tevva’s 7.5t battery-electric vehicle (BEV) has begun mass production at the company’s London facility this year. This will be followed by a 7.5t hydrogen-electric truck, which benefits from a hydrogen range-extender that enhances vehicle range to 354 miles (570 km). The Tevva BEV offers up to 140 miles (227 kilometres) from its 105-kWh battery on a single charge and is ideal for last-mile and urban delivery fleets.