Bosch Rexroth at Bauma 2025: how to improve the efficiency and safety of off-highway machines

At Bauma 2025, Bosch Rexroth will demonstrate how electrified off-highway machines can become more productive and safer with scalable digital solution modules and how they can be developed faster, easier and more cost-effectively.

At Bauma 2025, Bosch Rexroth presents new hardware and software modules for automation, electrification, connectivity and efficiency. The scalable and open-technology approach, including new hydraulic solutions from HydraForce, covers different machine sizes, drive types and objectives. This enables OEMs to equip themselves quickly and precisely with economical driving, assistance and work functions and thus set themselves apart from competition.

With Bosch Rexroth as a technology partner for the entire machine fleet, manufacturers can minimize development effort and focus more on machine and driving characteristics. Scalable solution modules relieve OEMs of time-consuming groundwork in order to design machines more efficiently, including functional safety and simplify operation.

Efficient development

One example of simplification in engineering is validated software modules that can be freely modified as part of the Try it First concept. The new BODAS Studio development environment, based on a standardized, open software architecture with a wide range of integration options such as MATLAB and Simulink from MathWorks, saves time when generating code. Young and experienced experts receive qualified answers to development questions via the myBODAS collaboration platform, which also offers a comprehensive knowledge database with AIsupported search and free access to the BODAS software modules.

Software-defined vehicles require Over-The-Air (OTA) services to roll out updates and new functions. BODAS Connect meets this requirement with a solution for OTA mass updates that also includes UDS-compliant controllers in mixed E/E environments. The newly introduced RCU Lite Connectivity Device provides an economic entry to telematics.

Bosch Rexroth at Bauma 2025: easy-to-operate machines

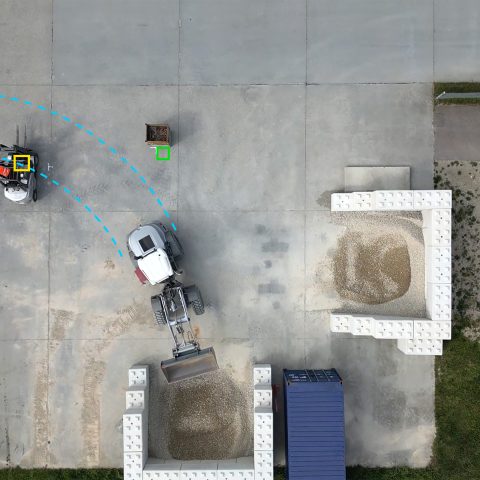

Semi-automated functions and advanced assistance systems enable greater safety and productivity on the construction site, even with less experienced operating personnel, for which Bosch Rexroth offers flexibly adaptable solution platforms. One example is the new Collision Avoidance System (CAS, below), which enables effective collision protection. The easily integrated CAS precisely detects objects and people using radar, ultrasound and smart cameras, warns of impending collisions or decelerates the vehicle until emergency braking. The Kinematic Position Sensing (KPS) in combination with multiple inertial sensors provide the technical basis for semiautomated functions such as weighing, virtual walls or grading on slopes.

More efficiency

Bosch Rexroth covers the entire chain of action from the joystick to the control system and sensors to the travel drive and working hydraulics. Across all drive types and machine sizes, the focus is on efficient solutions – for example drive systems and technologies as well as the eLION electrification portfolio (below), which now also covers the low-voltage range. The joint control platform eLION Power-and-Motion Control for low- and high-voltage on-board electrical systems ensures more efficient operation of electrified construction machinery in addition to cross-model synergy effects.

The enhanced EMP motor-generator series and the new compact MPR Performance Radial piston motor for small machines save valuable installation space, weight and energy. Also new is the modular RM Global valve platform which as a modular replacement for the well-known M4 valve, it covers the lower and medium flow range in a more flexible and efficient manner. The leading Onboard Electronics (OBE) in the agricultural sector have also been adapted for construction machinery.

The load and control valves from Rexroth Compact Hydraulics including the EDG, EDH, E-Valve and H-Valve series complement the innovative solutions from HydraForce, which was acquired in 2023. Highlights include the high-flow and energy-efficient Digital Boom Control Valve EHBL with the user-friendly HF-Impulse 2.0 programming tool and the oil condition sensor developed in collaboration with Tan Delta Systems. This sensor monitors fluid quality in real time, enabling proactive maintenance and helping to prevent unplanned downtime.