Carraro at Bauma: from the real to the virtual world

In line with the digital transformation process started over two years ago, Carraro Group has decided to take another step forward, also in how it narrates its products at trade fairs, starting from Bauma, and in remote relations with its partners.

In line with the digital transformation process started over two years ago, Carraro Group has decided to take another step forward, also in how it narrates its products at trade fairs, starting from Bauma, and in remote relations with its partners.

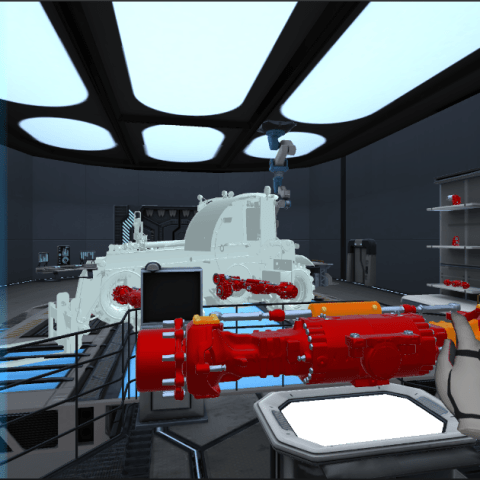

Carraro’s stand at Bauma is at the heart of this process, with an evolved Virtual Reality Room for visitors to tour a number of meta-environments where they can interact with Carraro’s products and solutions.

Besides offering an all-round immersive experience, thanks to special visors, the room opened up new frontiers and users could also engage remotely with Carraro staff, connected in real time from the R&D Centre at the headquarters in Campodarsego (Italy).

During this truly unique experience, MetaBrowsers were able to choose their journey themselves, directly interacting with products in 3D, playing videos and virtually visiting some locations of the Carraro plants.

More specifically, this year Carraro showcased three drivelines at Bauma, that perfectly exemplify the application needs of light construction equipment, in both hydrostatic and electric versions: one driveline for telescopic handlers, one for compact loaders and one featuring a versatile configuration – ideal for acompact excavator, or telescopic handler or compact loader.