Cummins and HVO

Here is Cummins' version of the use of HVO. Final focus on gensets

Even according to Cummins HVO is one of those acronyms conjured up as the elixir to escape the death sentence of ICE. Is it really clear to everyone what HVO is and how it can actually be used? Catherine Morgenstern, brand journalist for Cummins, speaks on the topic of alternative fuels.

HVO is part of the Cummins strategy to cross over the fossil fuels

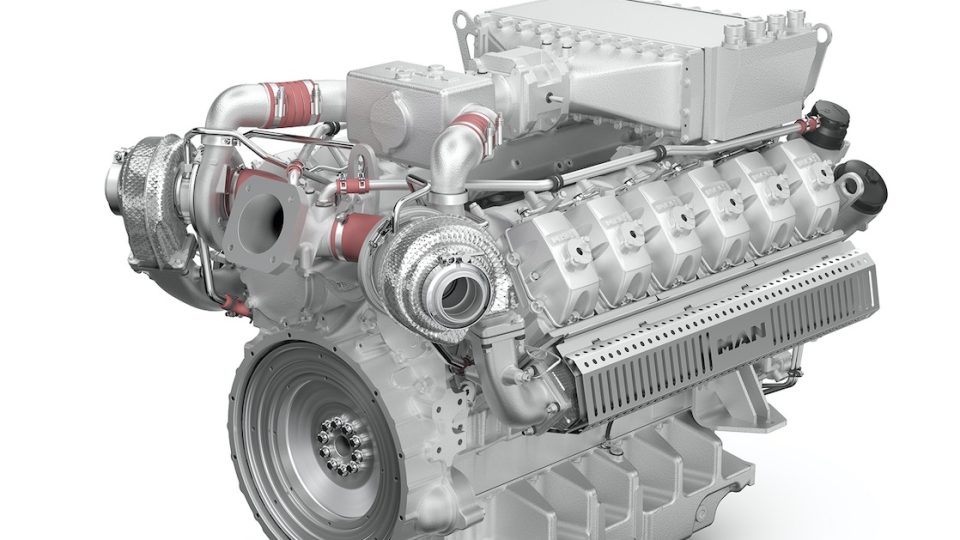

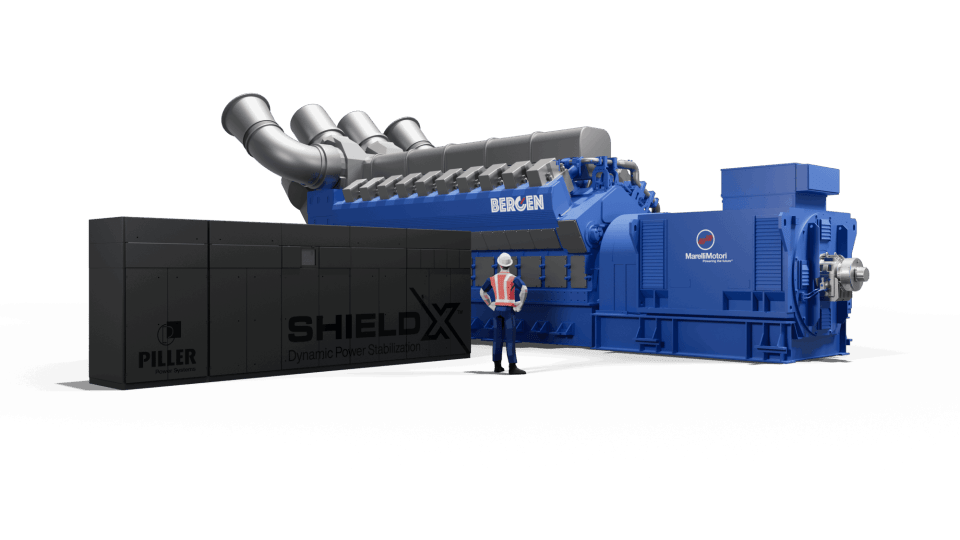

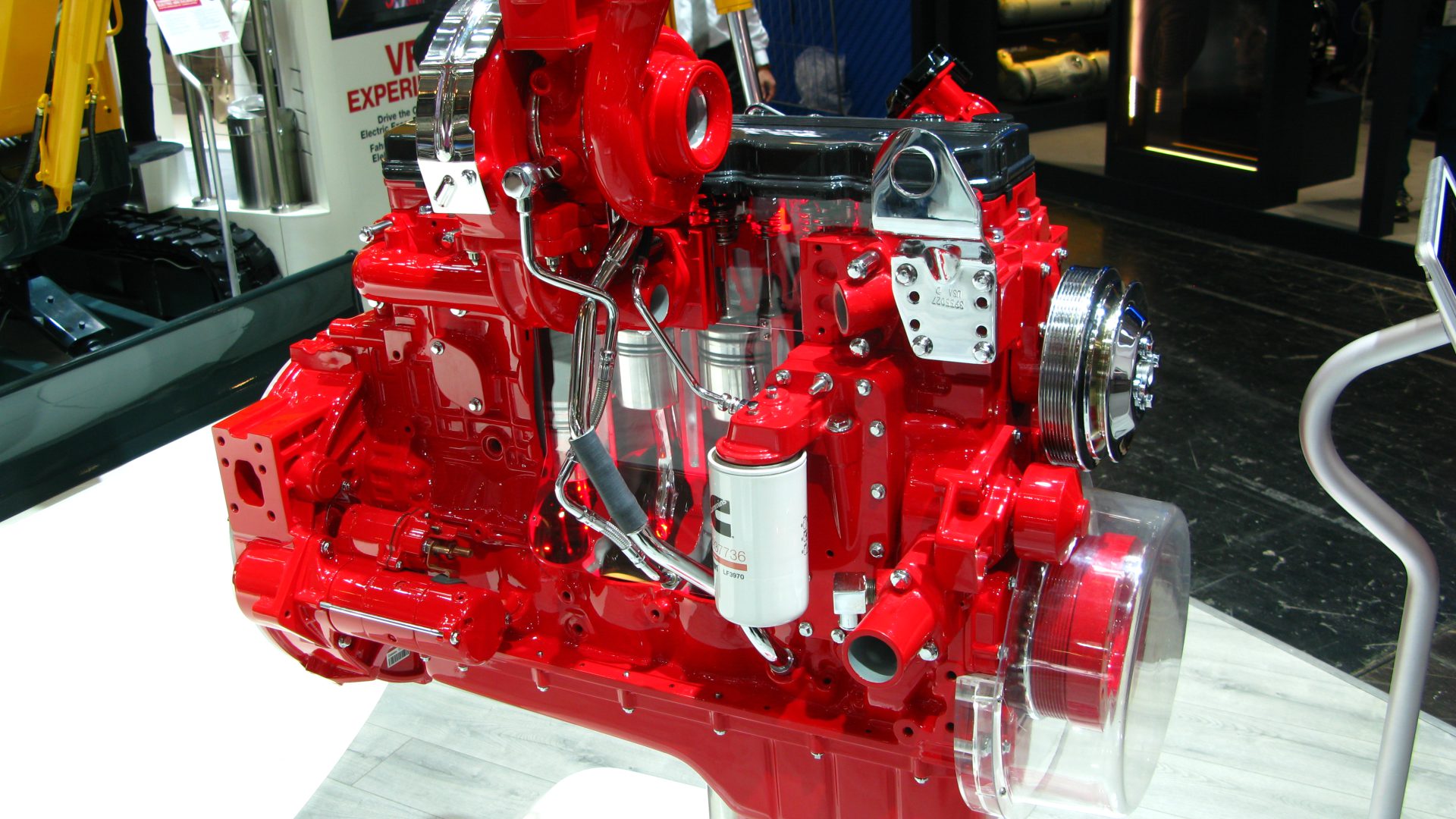

Hydrotreated Vegetable Oil (HVO) is a diesel-like fuel that can be produced without fossil resources by processing renewable waste lipids. Cummins’ entire line of diesel generator sets is approved for use with paraffinic fuels like HVO when used in Power Generation standby applications, providing a simple and efficient alternative to diesel for new or existing fleets of generator sets. This lower-carbon option enables Cummins customers, like Microsoft Corporation, to progress towards their decarbonization goals. “Microsoft is a valued partner, and we are delighted to collaborate with them and support their sustainability goals for cleaner power,” said Vipul Tandon, Executive Director, Global Power Generation at Cummins Inc. “Cummins has over 100 years of experience in integrating proven power system solutions with evolving technologies. This experience has provided us the flexibility to meet and exceed changing global standards, as well as the unique requirements of our customers.”

Paraffinic fuels, HVO and the difference from Diesel

Paraffinic fuels are an alternative to diesel with low sulfur and aromatics. They are derived from a variety of sources, the most common including natural gas, coal, plant oils and animal fats. Sometimes referred to as renewable diesel or green diesel, HVO is a low carbon fuel that is obtained by processing lipids such as vegetable oil, tallow, or used cooking oil, all made of paraffinic hydrocarbon. HVO fuel has chemical and physical properties like those of diesel fuel, however, its fossil-free composition and low carbon content differentiate it from diesel and make it attractive to those seeking a sustainable fuel option. HVO also has approximately 7% less fuel density, limited aromatic and sulfur content, and a higher cetane value versus diesel fuel. But even with these differences, HVO can be blended and used in any proportion with diesel which allows for ease of transition, especially in standby generator set applications where consumption of stored fuel is low. Physically and chemically, these fuels are the same fuel and meet the EN 15940 fuel specification. However, HVO has a lower life cycle carbon emission as compared to GTL fuels, because HVO is produced from renewable feedstocks while GTL fuels are produced from a fossil fuel, natural gas.

Using HVO on gensets

The detailed results of several tests conducted are published in a white paper that outlines the expected generator set performance when running on HVO fuel vs. diesel fuel. In summary, users can expect: no change in start-up and transient performance; up to 5% higher fuel consumption due to the lower energy content of HVO fuel; reduced power output of up to two percent on select generator set models; negligible NOx emissions changes; and significant reduction in particulate matter (PM) emissions and smoke, versus diesel fuel. EPA Tier 2 and TA Luft certifications remain valid with operation on HVO fuel. No changes or modifications to hardware or software are needed to run approved Cummins engines and generator sets on HVO fuels. Further Cummins standard and extended warranties apply on any generator sets approved to run on HVO fuel.

Mater of costs and supply chain

As a relatively new fuel source, the rate of adoption of HVO today is limited by its supply chain and higher cost, with higher adoption in markets where the use of diesel is curtailed. Supply chains are developing to serve these regulated markets, predominantly in parts of North America and Europe. Increasing demand driven by a combination of regulatory and customer ESG targets will drive increased production, which will subsequently lead to increased adoption. According to the IEA Renewables 2020 report, the average output in 2023-25 is anticipated to be 63 billion L, 30% higher than the 2019 level, with over half of this increase attributed to expanding HVO production in Singapore and the United States.