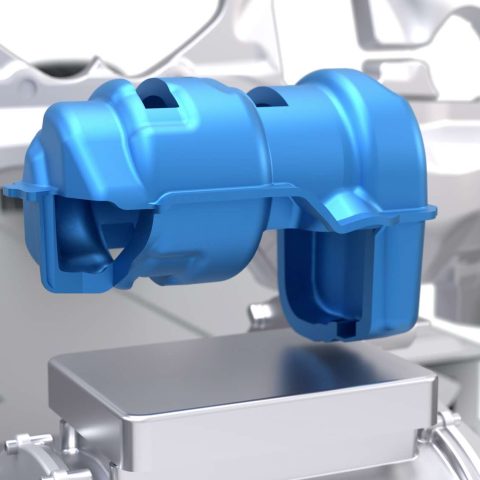

Acoustic encapsulation by Hutchinson

Hutchinson made a step forward in acoustic encapsulation for electric & hybrid vehicles components

To tackle the acoustic challenges of electric vehicles, Hutchinson has created an NVH (noise, vibration, harshness) encapsulation solution that features both acoustic and thermal properties, effectively reducing the noise from cooling compressors and e-motors.

Hutchinson takes care of noise for both BEVs and PHEVs

The advent of electric vehicles has also brought with it some acoustic issues, both for BEV and PHEV. Cabin noises can originate from various sources and occur whether the vehicle is moving, stopped, or parked, especially during fast charging. Previously, noises from powertrains and electric compressors were masked by combustion engines, but they are now more noticeable. Consequently, OEMs and equipment suppliers are seeking new methods to address noise pollution while adhering to new insulation regulations. This encapsulation solution provides a combination of vibration attenuation and absorption, particularly at high frequencies (>1000 Hz), reducing the noise from e-compressors and e-motors. Hutchinson’s high-end material expertise enhances the performance of e-compressors and the active cooling systems for e-motors with optimal thermal insulation properties. When combined with an NVH bracket, it delivers the best damping solution for e-compressors and e-motors.

About testing

Hutchinson conducts various acoustic tests, including sound absorption, transmission, insertion loss measurement, corrosion resistance, resistance to automotive fluids, and vibration. These tests are performed on the cover, lid, and their components, along with numerical modeling for thermal efficiency. Hutchinson adapts the design to the available space in the vehicle and the required technical constraints.

UFI FILTERS AND THERMAL MANAGEMENT

“The challenge was to find the best balance between comfort, noise reduction, mass minimization, industrial feasibility, and durability to ensure that the solutions meet the highest standards of performance and reliability. Through this system, we provide an effective response to environmental challenges and customer expectations,” explained Luis Lafuente, technical leader in Vittoria, Spain.