Argo tractors makes its own transmissions

Argo Tractors has opened in Italy's Motor Valley, in the province of Reggio Emilia, a hub dedicated to the manufacturing of transmissions

Argo Tractors has become more autarchic with the opening of the production facility dedicated to technological development and transmission manufacturing. A captive approach that strengthens the outlook for Landini, McCormick and the other brands owned by the group in Fabbrico (Reggio Emilia, Italy).

Argo Tractors manufactures transmissions in Emilia

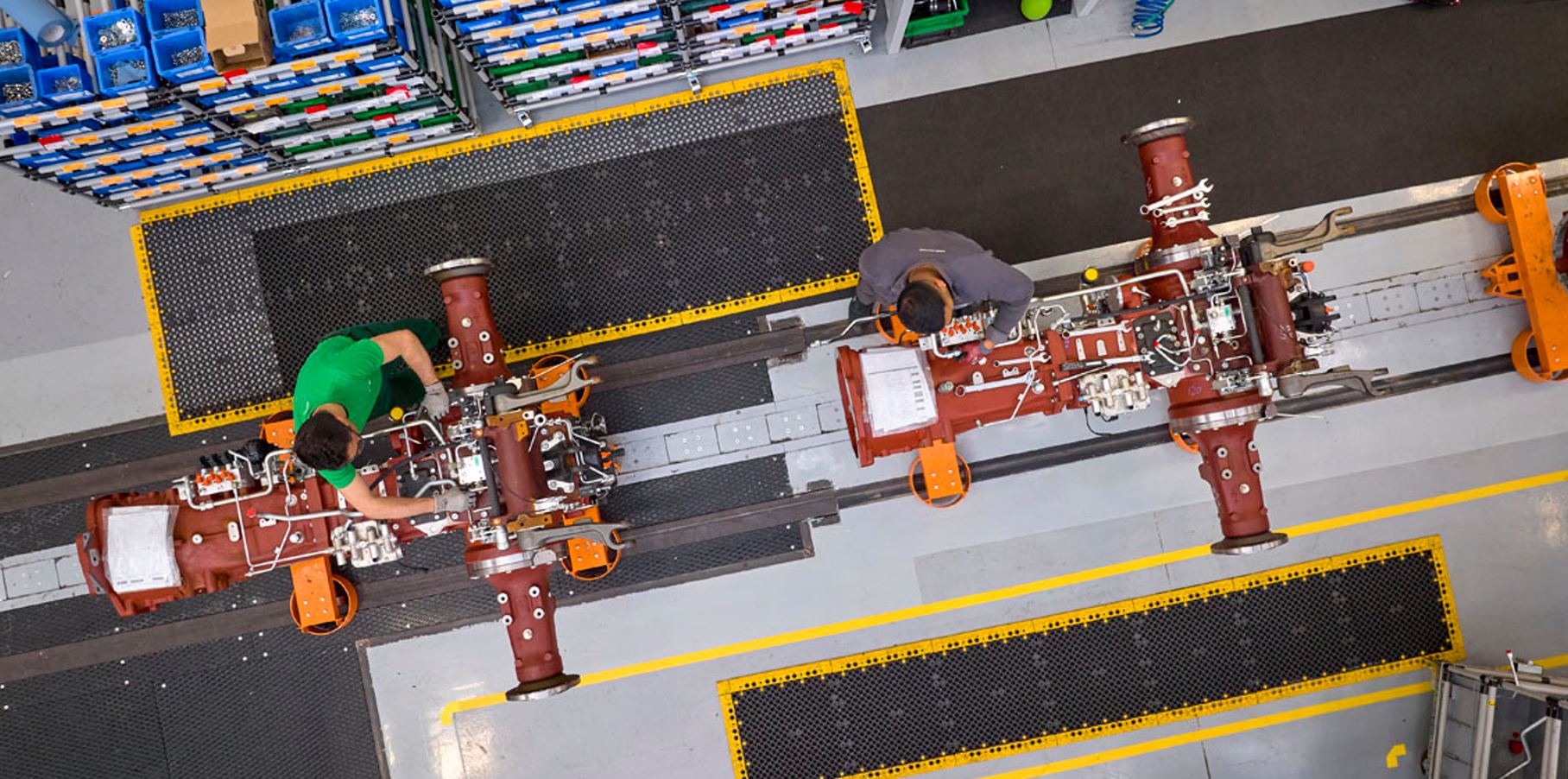

It is a very short distance from the headquarters that Argo Tractors has set up its transmission development centre, with four assembly lines differentiated by power output and range, each of which is supported by satellite pre-assembly areas: Line 1 assembles the transmissions of specialized and light and medium utility tractors; Line 2 assembles the transmissions of tractors destined for the Low Regulated markets; finally, Lines 3 and 4 are dedicated to medium-high power transmissions. Also in the Campagnola plant, as is already the case in the other Argo Tractors plants, the Kaizen industrial production philosophy of continuous improvement is applied, through the application of concepts that over the years have led to the development of lines served by specific and targeted components for each type of product. The new site, which became operational in January 2024, covers an area of 30,000 square metres and employs more than 150 people. The new centre also houses the testing area for the transmissions – mechanical and hydraulic – which, once assembled, are subjected to a punctual control and specific functionality tests.

About it

“It is the strategic component for excellence that makes an important contribution to the value of the tractor, and producing it in the new context means raising the level of specialization and quality control,” commented Alberto Morra, member of the Argo Tractors Board of Management. “Product evolution and innovation at Argo Tractors,” continues Alberto Morra, “has seen a marked acceleration in recent years. Hence the need to introduce a high level of specialization also on transmission assembly lines, through the creation of a dedicated plant, where to concentrate the resources and experience acquired over the years on this primary component, with the goal of achieving maximum production efficiency and the highest quality of the finished product. With the start-up of Argo Tractors‘ Transaxle department,” Morra concludes, “it has been possible to optimise assembly timing, making the cycle constant and regular, with a further overall improvement in quality.”