At IAA Accelera launches new endurance braking system for commercial electric vehicles

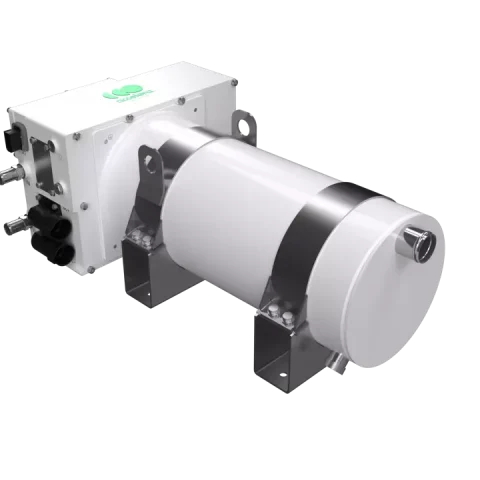

Accelera by Cummins, the zero-emissions business unit of Cummins, unveiled its new integrated brake chopper resistor (iBCR) at this year’s IAA Transportation in Hannover, Germany. The iBCR includes robust cyber security features with improved performance and reliability.

Accelera by Cummins, the zero-emissions business unit of Cummins, unveiled its new integrated brake chopper resistor (iBCR) at this year’s IAA Transportation in Hannover, Germany. The iBCR includes robust cyber security features with improved performance and reliability.

“Our new iBCR transforms traditional electric drive systems by integrating enhanced efficiency, safety and cost-effectiveness,” said Brian Wilson, General Manager of eMobility at Accelera. “By harnessing regenerative braking and optimizing energy management, we’re driving innovation while shaping a cleaner, greener mobility landscape.”

Leveraging the technology from the Accelera ELFA 3 inverter series, the iBCR is a versatile system designed to address two critical aspects of electric commercial vehicle performance—electrical endurance braking and energy efficiency. Acting as an electrical equivalent of a mechanical retarder, the excess energy generated from braking is redirected to the liquid-cooled resistor, where it dissipates as heat. This innovative approach ensures efficient energy management and improved braking performance.

Key features of the IBCR

- Enhanced regenerative braking: Electric commercial vehicles benefit from regenerative electric braking, where the electric motor acts as a generator during braking. The iBCR captures surplus energy and converts it into heat, which can be used to heat the vehicle’s cabin or to temper the battery system. This not only enhances efficiency, but also contributes to overall energy savings.

- Cost-effective compliance: By integrating with a liquid-cooled resistor, the compact iBCR offers an economical solution to meet the UN ECE R 13 European regulatory standards. It helps optimize battery size and avoids the need to carry buffer capacity. The iBCR also helps relieve strain on friction brakes to enable improved durability and reduce maintenance efforts.

- Safety improvements: The iBCR has increased responsiveness and provides immediate room for uninterrupted endurance braking, with the ability to dissipate excess energy as heat up to 150-kilowatt (kW) output power. This makes it suitable for heavy-duty applications that require endurance-braking ability. The iBCR plays a crucial role in maintaining safety within electric drive systems, providing reliable performance in demanding scenarios.

Accelera is displaying several of its next-generation technologies at IAA, including a modular 300kW hydrogen fuel cell engine, compact high-power eAxles, next-generation batteries and efficient traction systems. Many of these products can be easily integrated into existing commercial vehicles or paired with other Accelera products, providing a seamless transition to lower- or zero-carbon applications for customers.