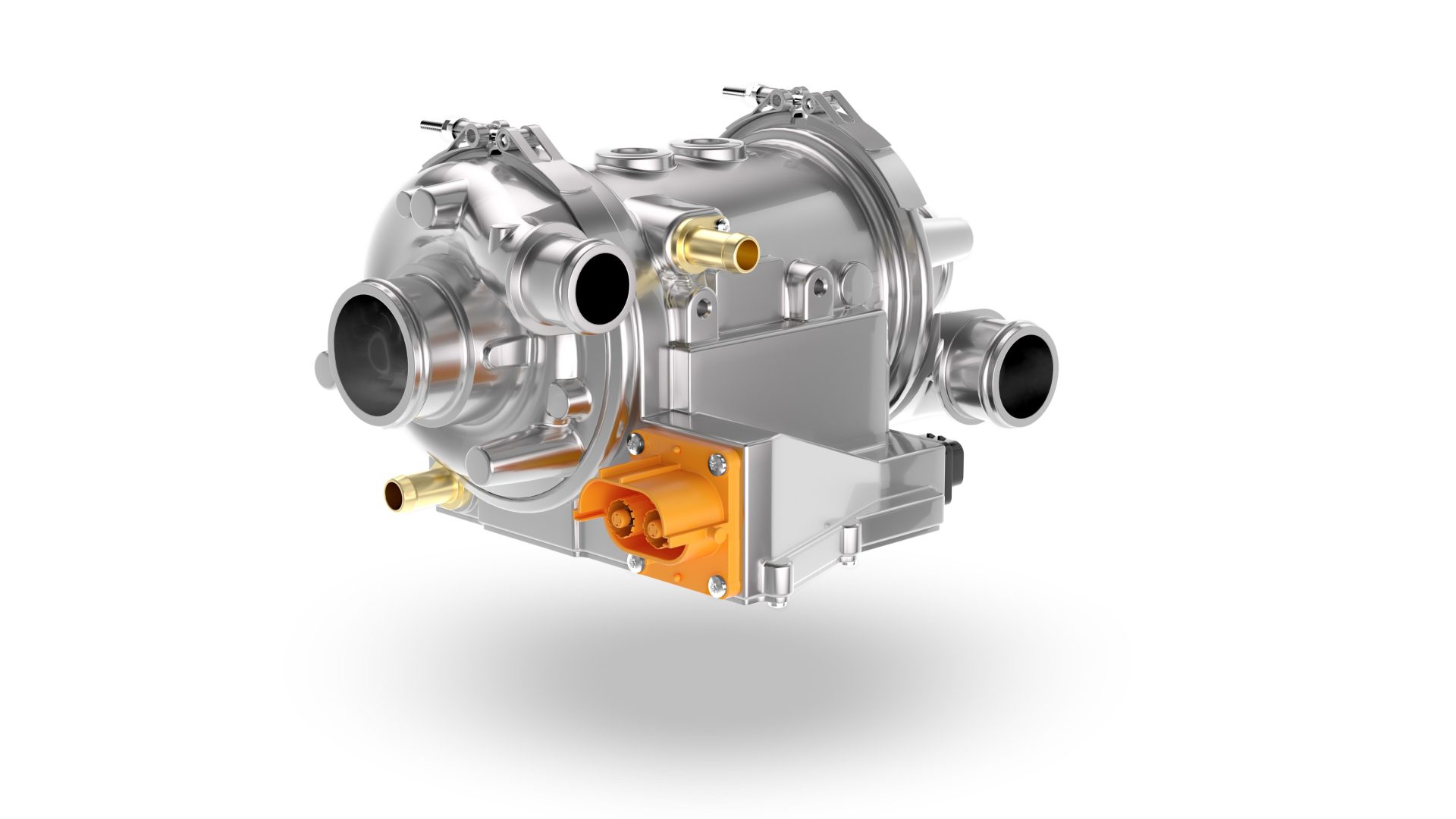

At IAA ZF presents Hydrogen Recirculation Blower for FC-powered commercial vehicles

Shown for the first time at the IAA, the ZF Hydrogen Recirculation Blower works in conjunction with ZF’s Fuel Cell Air Compressor to optimize the efficient operation of fuel cell systems.

At the IAA Transportation 2024, ZF Commercial Vehicle Solutions (CVS) division unveiled its latest addition to its e-mobility portfolio, a new Hydrogen Recirculation Blower. Designed to optimize hydrogen levels for fuel cell-powered vehicles, ZF’s Hydrogen Recirculation Blower recirculates unused hydrogen to improve hydrogen consumption and performance. Highly efficient, the system draws minimum power from the fuel cell system to reduce hydrogen usage.

The Hydrogen Recirculation Blower works in conjunction with ZF’s Fuel Cell Air Compressor, which was announced in April 2023 (above). The compressor supplies air to the fuel cell stack, facilitating the chemical reaction between hydrogen and oxygen, and uses turbo technologies for improved efficiency. Together, these products form part of ZF’s growing Balance of Plant (BoP) portfolio, supporting the efficient operation of fuel cell systems in commercial vehicles. Similar to the Fuel Cell Air Compressor, the Hydrogen Recirculation Blower is built to be durable, throughout the lifetime of the commercial vehicle, helping to reduce its Total Cost of Ownership (TCO).

“ZF has applied its extensive expertise in system integration and air bearing systems to develop these innovative products,” says Christian Brenneke, Head of Innovation & Development at ZF’s Commercial Vehicle Solutions Division. “The newly unveiled Hydrogen Recirculation Blower, combined with our fuel cell air compressor, is part of our expanding full-flex e-mobility portfolio. These innovations demonstrate how our products for fuel cell systems are driving decarbonization in a technologically open manner alongside our growing range of decarbonized technologies.”

The Hydrogen Recirculation Blower, based on the turbomachinery concept, is compact, lightweight and optimized for efficiency. Its ultra high-speed electrical motor can reach up to 100,000 RPM, using air bearing technology to eliminate the need for lubrication and prevent contamination of the fuel cell stack. This ensures optimal efficiency and high media mass flows. Additionally, the system also includes an integrated inverter that supports 800 V high voltage systems.

Hydrogen recirculation is vital for the longevity and efficiency of the fuel stack. Leading in the industry, ZF’s Hydrogen Recirculation Blower solution efficiently manages water and inert gases in the anode path. Thanks to the use of the patented electric media-gap motor technology, the water separator will be integrated directly in the device, and the need for active cooling is eliminated. This offers great advantages in packaging and less complexity in the system assembly.

Read also: ZF and Freudenberg announce fuel cell drive partnership