BeyondBattRec project: 7.45 million EU funding for pre-processing of Lithium-ion batteries

Coordinated by Aalborg University in Denmark, BeyondBattRec unites a total of 12 leading partners, including VARTA Microbattery, Siemens, Accurec Recycling, Andaltec, UVR-FIA, Shift Materials, University of Jaén, EurA, Coventry University, ACIB, and Tes AMM, from seven European countries to develop groundbreaking technologies for battery recycling.

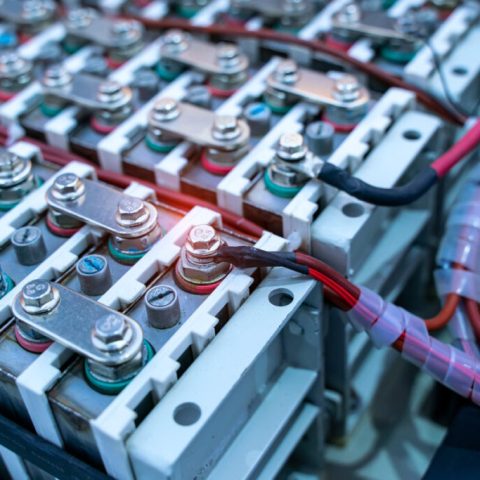

Despite the importance of Li-ion batteries in achieving the EU’s climate ambitions, the inefficiency of current recycling practices limits the recovery of valuable materials, perpetuating dependence on imported resources and creating significant environmental challenges. The BeyondBattRec project is poised to change this by integrating advanced technologies that align with Europe’s circular economy goals. By recovering up to 95% of critical metals like cobalt, nickel, and copper, and 70% of lithium, the project aims to drastically reduce waste and emissions while strengthening Europe’s resource independence.

Coordinated by Aalborg University in Denmark, BeyondBattRec unites a total of 12 leading partners, including VARTA Microbattery, Siemens, Accurec Recycling, Andaltec, UVR-FIA, Shift Materials, University of Jaén, EurA, Coventry University, ACIB, and Tes AMM, from seven European countries to develop groundbreaking technologies for battery recycling. Running for 48 months, BeyondBattRec aims to enhance battery recycling in Europe, making it more efficient, sustainable, and economical by developing innovative pre-processing technologies and protocols for recycling both metallic and non- metallic components of lithium-ion batteries

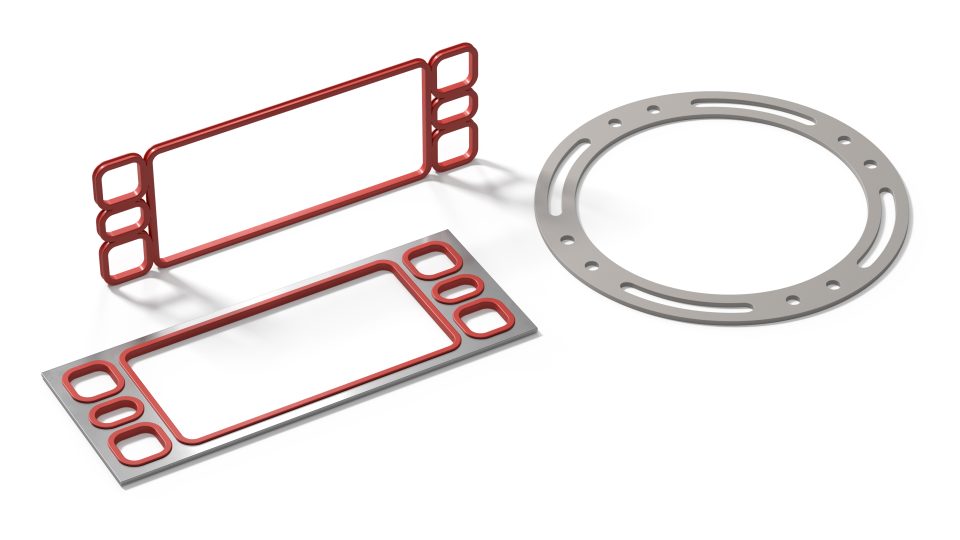

At the core of the project is the development and validation of innovative technologies for sorting, deactivating, dismantling, and recovering battery components. These technologies will enable the high-precision recycling of materials such as anodes, cathodes, electrolytes, solvents, binders, and strategic metals. BeyondBattRec will also evaluate the techno-economic feasibility of these processes, ensuring they are both practical and scalable for industrial adoption.

The project aims to establish Europe as a leader in innovative battery recycling technologies, building a circular value chain that drives both industrial growth and societal benefit. By enhancing the EU’s industrial resilience and resource independence, the project directly supports the objectives of the European Green Deal, facilitating the sustainable transformation of the energy and transport sectors.