Bonfiglioli Evox: after EVO another (almost homonymous) milestone

Bonfiglioli Evox. On September 23rd, we attended, telematically speaking, a double presentation by Bonfiglioli: Evox and Axiavert – a coaxial gearmotor and frequency inverter respectively. In 2019, Bonfiglioli (HERE our catch-up at Agritechnica) had the highest ever turnover, with 973 millions euros and invested in order to enhance its portfolio and became a complete specialist. Said […]

Bonfiglioli Evox. On September 23rd, we attended, telematically speaking, a double presentation by Bonfiglioli: Evox and Axiavert – a coaxial gearmotor and frequency inverter respectively. In 2019, Bonfiglioli (HERE our catch-up at Agritechnica) had the highest ever turnover, with 973 millions euros and invested in order to enhance its portfolio and became a complete specialist. Said Fausto Carboni, Bonfiglioli’s CEO: «Starting from June 2020, the order intake has been significantly higher, and in August the total company performance was 13% higher than August 2019. All countries have set a remarkable turnover recovery in the month of August; China has increased its growth rate to more than 60%, India reached a 10% growth, while western economies, despite much better results, are still struggling, with the exception of Germany, up by 40%.»

The 5 pillars of Bonfiglioli Evox

Now we approach Evox. The pilosophy that leads the Evox project is based onto the same pillars: simplicity, efficiency, versatility, flexibility performance and IoT readiness.

Probably the most important need was moving from a subassembly logic to a component based logic. To Bonfiglioli they can say: ‘mission accomplished’. According with International Energy Agency 40 percent of the global electricity consumption in basically generated from electric motor driven systems. What does it mean? Easy: there is room for improvement in efficiency and Bonfiglioli has understood this.

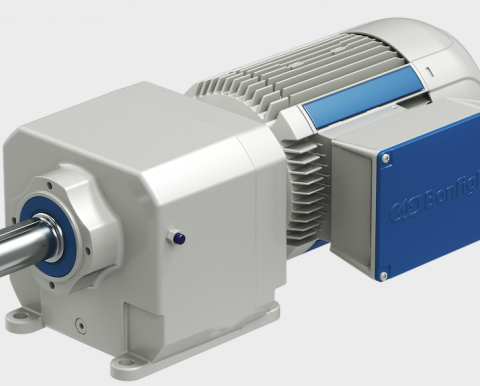

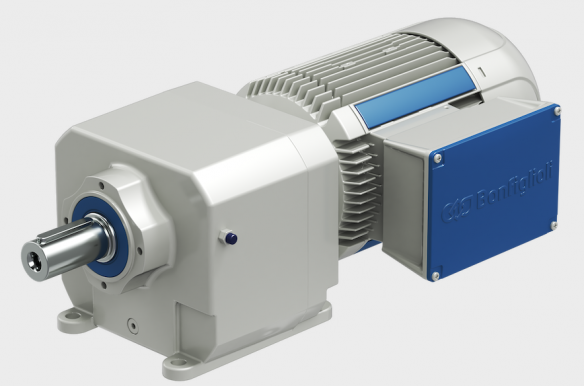

The official reports that “Bonfiglioli – the Italian drive specialist – is announcing Bonfiglioli’s new geared motor platform that sets an innovative approach for the geared motor market. Efficiency, reliability, modularity and performance were the drivers behind the development of the EVOX geared motor platform. Thanks to an enhanced modularity concept, EVOX represents a step forward for Bonfiglioli’s product range, with solutions for a wide spectrum of applications. The uncompromised selection of commercial components, the broad use of gear grinding processes, and specific ‘low noise’ gear design make EVOX a benchmark product in terms of reliability and efficiency. The first products of the EVOX geared motor platform are the new Helical In-Line Gearmotor CP combined with the new Asynchronous IE3/NEMA premium high efficiency electric motors. The synergies between these two new concepts create an efficient, strong, small and simple gearmotor ecosystem. The in-line gear units will be first released in 6 different sizes: 55, 100, 200, 335, 500, 650 Nm with motor power between 0.12 and 15 kW IE3. The EVOX Platform is characterized by a new simple and clean design, suitable for any application environment furtherly featured by optional C3/C4 surface protection or by ATEX rating (explosion proof protection).

So good for higher precision demanding applications

The EVOX CP gear unit is ideal also for higher precision demanding applications, thanks to the reduced backlash configuration available in the standard catalogue. EVOX CP also helps eliminate any customer experienced friction, thanks to an innovative lubrication concept that allows the gearmotor to be used in any mounting position, thus overcoming the need of changing oil level and oil plugs configuration. This will give our customers the freedom and flexibility to use the product in any orientation. The geared motors will be available both in compact and IEC flanged versions, allowing customers to choose between a standardized motor and a dimensionally optimized configuration. BXN motor, the IEC standard, and MXN motor, the compact version, share most of the configuration and options, including dynamic brake, incremental and absolute encoders, thermal sensors and switches. The new standard motor terminal box is shaped with its 9 PIN connectors, for up to 8 different voltages at 50Hz or 60Hz power supply with a single winding, making it suitable for the EU, US, Indian and Australian market. Further 6 windings cover the rest of the world. Bonfiglioli research and development team designed the entire EVOX platform to enable condition monitoring and predictive maintenance, both sensored and sensorless. During the development of the EVOX CP gearmotor, a complete mathematical model relating thermal behaviors of the gearmotors to the electrical variables has been developed. This will enable effective sensorless condition monitoring and predictive maintenance directly managed by our AxiaVert Inverters acting as an edge computer. In the near future, the EVOX Platform will include other product range extensions.”