BorgWarner: Viper and inverters

BorgWarner inverters strategy found in Viper family an excellent support. P3 hybrid drive module will be powering some European AWD SUVs

BorgWarner investment in the inverters follows the product diversification with a view to electrification. The company has secured a contract with a major OEM to supply high voltage inverters for battery electric vehicle (BEV) platforms including a variety of passenger cars and trucks. The business award marks the company’s largest major silicon carbide based (SiC) inverter win and the first silicon carbide based inverter win in North America.

BorgWarner to produce inverters from 2024

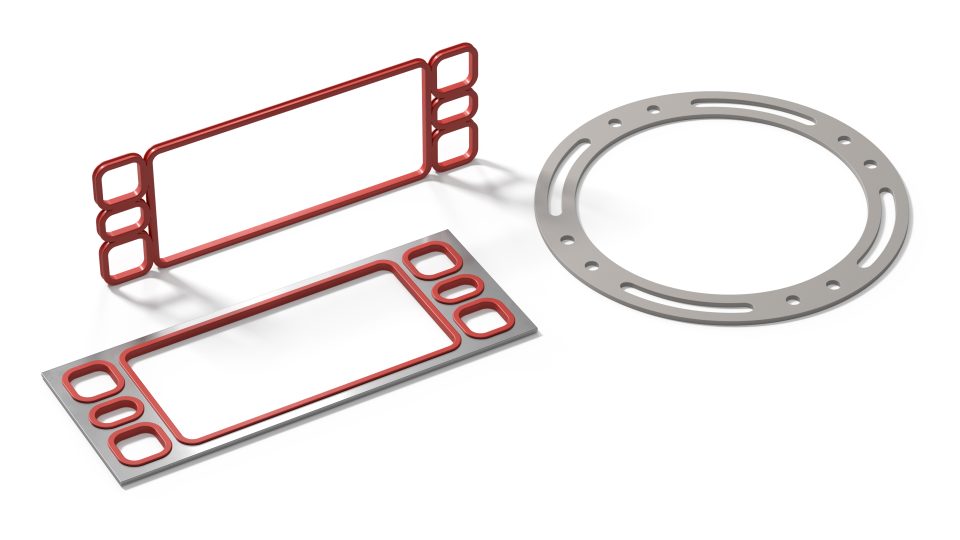

The inverters leverage BorgWarner’s Viper family of scalable power modules, manufactured with SiC materials for superior efficiency. These specific features allow for a higher voltage operation and higher current densities compared to traditional inverter technologies. BorgWarner’s inverter performance and scalability, cost, size optimization and global manufacturing footprint contributed to securing the business win. The launch of the inverter is slated for 2024.

U.S. Department of Energy Award for High Power-Dense Inverter

The American company received $4.97 million from U.S. Department of Energy (DOE) Award for the development of a Scalable Ultra Power- dense Extended Range (SUPER) inverter. This research and development project is one of 24 university and industry-led projects that collectively were awarded $60 million in an effort to reduce CO2 emissions from the transportation sector.BorgWarner is leading this 39-month project and working with Infineon Technologies Americas Corp., PolyCharge America, Inc., the National Renewable Energy Laboratory and Virginia Tech as partners to bring the SUPER inverter to fruition. Wolfspeed, Inc. will be a key supplier. “For this project, we will be leveraging our experience with our unique and high-performing 800V Viper silicon carbide based inverter, advancing the concept with a building block approach and increasing component integration to achieve higher performance targets and ultimately expand its commercial potential,” said Stefan Demmerle, President and General Manager, BorgWarner PowerDrive Systems. “We expect the number of high-voltage EVs to sharply increase in the coming years and this scalable, high power density inverter will help expedite adoption.”

P3 hybrid drive module

Fully integrated P3 hybrid drive module will soon be powering a variety of front-wheel and AWD SUVs for a major European performance based OEM. The unique, power-packed P3 solution enables significant fuel economy gains, CO2 reduction and was entirely custom-designed inhouse by BorgWarner, featuring a motor, power electronics, gears and water cooling, all integrated within one unit. Among the key features of BorgWarner’s latest drive module is the permanent magnet motor and complementary inverter that BorgWarner built from the ground up for this application. The electric motor features BorgWarner’s patented and proven S-wind wire forming process for electric motors and alternators, and the system is capable of peak power up to 25 kW and enables a substantial reduction in CO2 emissions. The P3 module also encompasses disconnect and energy regeneration capabilities.