Cummins to advance engine performance with two-stage turbocharger

Commercial engines need advanced technology to be efficient and meet strict emissions standards. Therefore, Cummins offers various turbo technologies, like fixed, variable, and two-stage turbos, all designed to improve efficiency and reduce costs.

Cummins Turbo Technologies (CTT) has been developing and testing turbocharger technologies with a special focus on medium-heavy duty engines. For the past, several decades Cummins Components and Software has delivered durable and reliable turbocharger solutions with the Holset brand.

Commercial engines need advanced technology to be efficient and meet strict emissions standards. Therefore, Cummins offers various turbo technologies, like fixed, variable, and two-stage turbos, all designed to improve efficiency and reduce costs.

What is a two-stage turbocharging system?

Turbochargers give engines more power by pushing extra air into the cylinders, making the fuel burn more efficiently. They do this by using energy from the engine’s exhaust gas to spin a turbine. The turbine is connected to a compressor by a shaft and as the turbine spins, it also spins the compressor, which forces more fresh air into the engine.

A single-stage turbocharger uses one turbine and one compressor. If the turbocharger is large, it provides higher torque at high engine speeds, giving good peak power performance. However, it may not deliver as much power at low speeds. On the other hand, a smaller turbocharger is better at providing power at low speeds but may struggle to give enough boost for peak power at high speeds.

A two-stage turbocharger uses both a small and a large turbo. The smaller turbo spins up quickly to deliver an instant boost, improving torque and responsiveness at low speeds or in high-altitude conditions. The larger turbo then kicks in to provide smooth, consistent power at higher speeds. This setup allows for better performance across a range of conditions, not just at low or high speeds.

In a two-stage system, exhaust gases are managed by bypass systems called “wastegates”. These wastegates adjust based on engine speed to optimize the performance of the turbocharger. With rising fuel prices and stricter emissions standards, engines need to be more efficient. Two-stage turbochargers provide a strong solution by balancing low-end torque and peak power, offering better performance at higher altitudes, and enhancing overall fuel efficiency.

How does a Cummins’ two-stage turbocharger work?

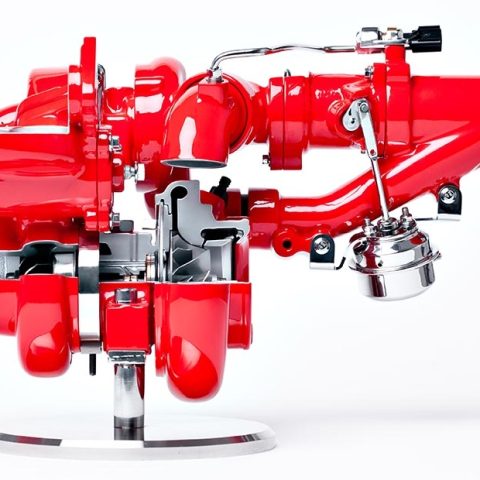

A two-stage turbocharger system uses two turbochargers positioned along the exhaust path. The one closer to the engine is the high-pressure (“HP”) turbo and the one farther away is the low-pressure (“LP”) turbo. Each turbocharger has a compressor and a turbine.

The system’s efficiency and performance come from the balance of hot exhaust gases and fresh air moving through both the HP and LP turbochargers.

Hot exhaust gases from the engine enter the HP turbine first, where energy from the high-temperature gas is extracted, causing the turbine blades to spin. The spinning of the turbine blades powers the HP compressor, which further compresses air that has already been pressurized by the LP compressor. This compressed air allows for higher pressure ratios and more air in the engine’s combustion chamber. The remaining energy in the exhaust gases then drives the LP turbine, which in turn powers the LP compressor to pressurize more air for the HP stage.

Bypass valves regulate the exhaust gases. At low speeds, the valves stay closed to direct more energy to the HP turbo. As speed increases, some exhaust gas bypasses the HP turbine, redirecting more energy to the LP turbo.

Two-stage turbochargers offer better “turbo matching,” which improves transient response, peak torque and peak power, making them highly efficient across the engine’s torque curve. This makes them ideal for high-power engines, engines with high air demands (e.g., hydrogen internal combustion engines) and applications that operate at high altitudes.