Dana and Bosch join forces for manufacturing key components of fuel cell stacks

Dana has signed a long-term cooperation agreement with Robert Bosch to mass produce metallic bipolar plates for fuel-cell stacks. Dana's licensed intellectual property will serve as the foundation for the companies to co-develop and co-produce the next generation of metallic bipolar plates and drive excellence across manufacturing processes.

Dana has signed a long-term cooperation agreement with Robert Bosch to mass produce metallic bipolar plates for fuel-cell stacks. Dana’s licensed intellectual property will serve as the foundation for the companies to co-develop and co-produce the next generation of metallic bipolar plates and drive excellence across manufacturing processes. Dana’s metallic bipolar plates are an integral component in the fuel cell stack and deliver improved cost, performance, and seamless assembly, aiding OEMs in realizing commercialization of fuel-cell-powered mobility.

Dana and Bosch: plates for fuel cell stacks

«Dana has innovated a game-changing metallic bipolar plate technology that is helping customers deliver zero-emission, fuel-cell powered vehicles at a cost that enables market adoption today», said Antonio Valencia, president of Dana Power Technologies and Global Electrification. «This agreement demonstrates our ability to deliver a market-ready metallic bipolar plate that eliminates the traditional cost, complexity, and performance barriers, which is a crucial step for the growth of the fuel-cell market».

The highly durable bipolar plate is designed to meet the extreme demands for sealing, coating, and absolute precision of the extra-fine embossing structures. Dana’s metallic bipolar plates are indeed an integral component in the fuel cell stack.

Potrebbe interessarti

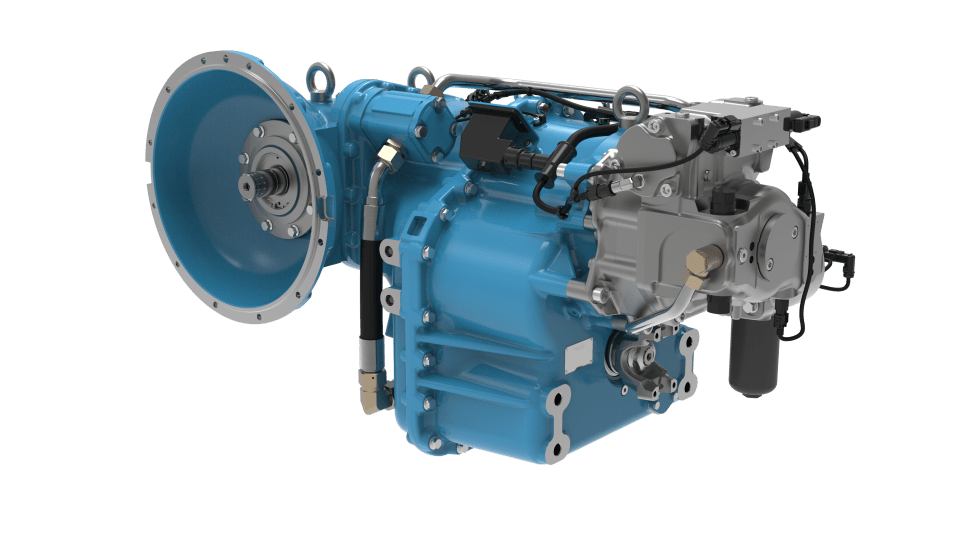

Dana introduces new Spicer HVT1 transmission for agriculture telehandlers

The plates are expected on the market in early 2022

The Bosch overall fuel cell stack system know-how will enable both companies to further improve the bipolar plates design for further generations with regards to cost competitiveness and performance. Furthermore, Bosch contributes strong process competence in mass production, especially on laser welding, testing, and automation concepts. This will support a successful launch of the serial production of bipolar plates.

To address increasing market demand, the total production volume will exceed 100 million metallic bipolar plates for Europe, Asia Pacific, and North America. The plates are expected to support fuel-cell powertrains for commercial-vehicle applications beginning in 2022.