Delta Electronics and Texas Instruments together to develop advanced EV power systems

Delta, a global leader in power management and a provider of IoT-based smart green solutions, announced the establishment of a joint innovation laboratory with Texas Instruments.

Delta, a global leader in power management and a provider of IoT-based smart green solutions, today announced the establishment of a joint innovation laboratory with Texas Instruments (TI), a global semiconductor leader. With TI’s innovative technologies and ample experience in digital control and gallium nitride (GaN) and Delta’s core competence in high-efficiency power electronics, the joint lab will not only deepen the long-term relationship between the two companies, but also enhance the power density and performance of Delta’s own EV power systems, to ultimately strengthen its core competitiveness in the field of electric vehicles (EV).

James Tang, Executive Vice President of Mobility at Delta and Head of its Electric Vehicle Solutions Business Group, stated, “Delta has been developing high-efficiency automotive power products, systems and solutions since 2008 to help reduce transportation-related carbon emissions. Through the establishment of this joint innovation laboratory with Texas Instruments, Delta intends to leverage TI’s abundant experience and advanced technology in digital control and GaN to enhance the power density and performance of our EV power systems. With more leading-edge product development and design capabilities, we aim to achieve closer technology exchange and collaboration to accelerate product development and improve product safety and quality. We look forward to furthering our technology leadership and creating a win-win situation in the rapid developing electric vehicle market.”

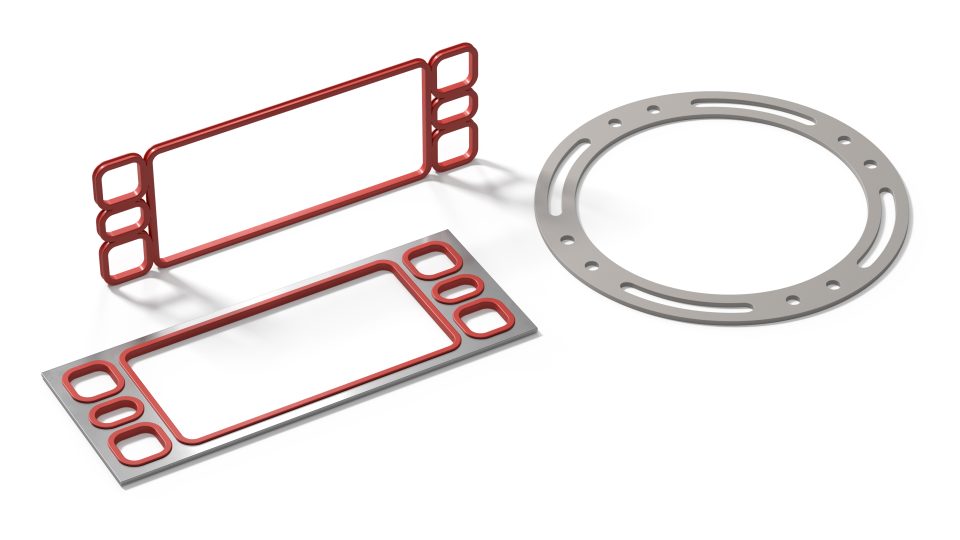

“The transition to electric vehicles is key to helping achieve a more sustainable future, and through years of collaboration with Delta Electronics, we have a solid foundation to build upon,” said Amichai Ron, senior vice president for Embedded Processing at Texas Instruments. “Together with Delta, we will use TI semiconductors to develop EV power systems like onboard chargers and DC/DC converters that are smaller, more efficient and more reliable, increasing vehicle driving range and encouraging more widespread adoption of electric vehicles.”

In response to the era of software-defined vehicles (SDV), Delta has built up joint labs with several international semiconductor companies that focus on automotive power electronics and digital control, to meet the future innovation and higher requirements for power efficiency and safety in next generation EVs. The joint innovation lab with TI is expected to accelerate development and full validation of Delta’s automotive products to help international car manufacturers develop key architectures and layouts for next-generation EVs with better product quality than the competitors.