Deutz towards volume production of hydrogen engines. With Mahle

Deutz chooses automotive supplier Mahle to supply hydrogen engine components. Full production for stationary application will start in 2024.

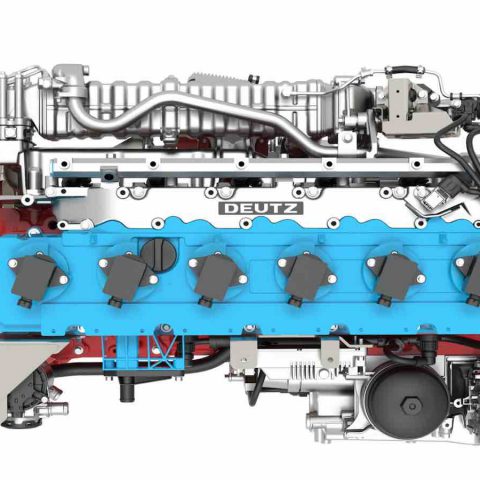

Deutz is taking a major step toward volume production of hydrogen engines for the commercial vehicle sector with its decision to source components from Mahle in future. The automotive supplier has been awarded a volume contract to develop and deliver power cell units. These will be built into the production engines scheduled to enter the market at the end of 2024. The Deutz engines will initially be used in stationary applications such as generators, with plans in place to extend their use to mobile applications in the future.

Sebastian C. Schulte, CEO of Deutz: “We need a range of technical options in order to keep the world moving. It remains uncertain what a carbon-neutral excavator or combine harvester might look like. Drive systems that are constantly in use and move large loads could be based on a number of different technologies. One of them is the hydrogen engine, and the success of our pilot projects shows their potential for use in commercial vehicles. In Mahle, we have a strong partner at our side who will help us to start volume production of our hydrogen engines at the end of 2024.”

The design of the hydrogen engine is based on conventional combustion engine technology, but it runs on hydrogen instead of fossil fuels. As the hydrogen combustion process does not generate any CO2, the engine meets the EU’s zero-emissions requirements.

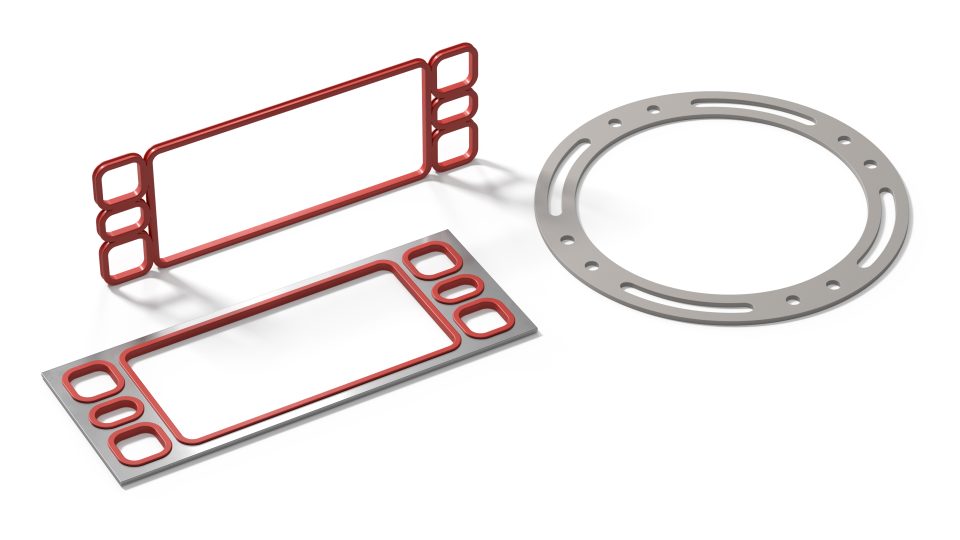

Mahle has been working on components for hydrogen engines for many years and has considerable expertise in combustion engines and alternative fuels. The power cell units consist of a piston, piston rings, and piston pin, which the Stuttgart-based technology company has adapted from conventional diesel technology. The components have already proven their reliability in the company’s own test center for hydrogen applications.

“We believe that hydrogen is a key element of sustainable mobility, especially in the commercial vehicle sector. This project with Deutz is both a milestone and a beacon, as it shows that there are technological alternatives to electrification for achieving climate neutrality,” says Arnd Franz, CEO and Chairman of the Management Board of the Mahle Group.

Both companies are united by the belief that mobility can only be transformed through innovation and an open approach to new technologies. Using hydrogen to make the combustion engine more climate-friendly unlocks the potential of all available technologies.