Feintool and SITEC announce partnership with Impact Coatings

Feintool and SITEC announced their latest production partnership with industry-leading Swedish coating specialist Impact Coatings. This cooperation further strengthens their capability to provide customers with the entire process chain in the production of ready-to-install metallic bipolar plates and interconnects for fuel cells and electrolyzers – from early development to high-volume production.

As leading manufacturers of metallic high-precision components for fuel cells and electrolyzers, Feintool and SITEC are continuously enhancing their manufacturing processes to address the needs of the hydrogen industry. With Swedish Impact Coatings they cooperate with a proven, reliable, and globally present specialist to further evolve their state-of-the-art development and production capabilities.

Impact Coatings’ expertise lies in physical vapor deposition (PVD), a clean coating process for the modification and enhancement of surface properties with minimal environmental impact.

Fuel cells are electrochemical energy converters that generate electricity from hydrogen and oxygen. They emit only water vapor. This is how fuel cells power electric vehicles and, for example, emergency power generators. They offer a clean alternative to fossil fuels and thus contribute to a greener future. Electrolyzers use the same principle as fuel cells in reverse to store energy in hydrogen.

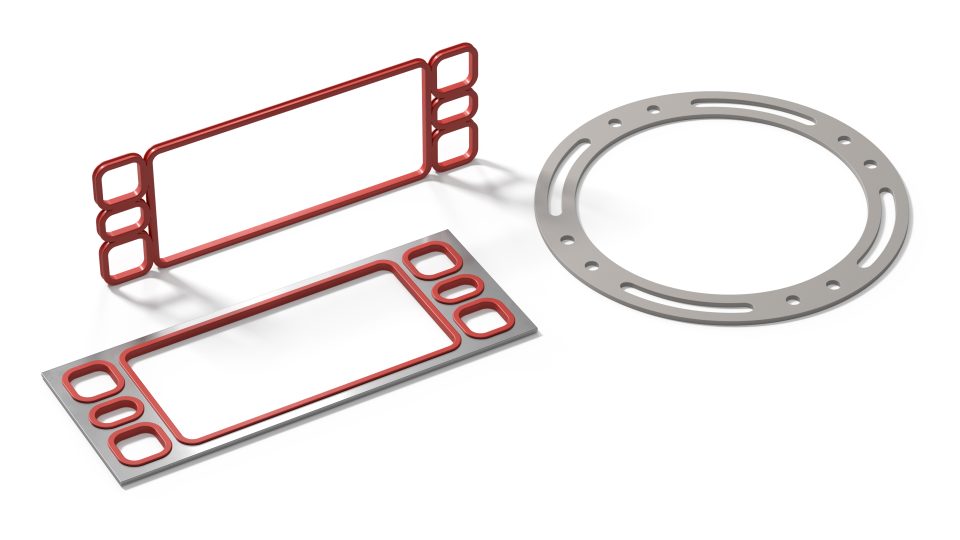

The metallic bipolar plates and interconnects constitute the cores of fuel cells and electrolyzers. These high-precision components enable efficient gas flow, cooling and electrical connection at low production cost. Several hundred plates are layered to form the fuel cell or electrolyzer stack.

Feintool and SITEC’s strategic goal is to become one of the world’s leading suppliers of metallic bipolar plates and interconnects.