Improving lithium-ion battery production. With the help of Mitsubishi Electric

The future of the lithium-ion battery sector is incredibly bright. As demands grow, so does the pressure on manufacturers. How can they effectively scale-up and improve their operations to turn the challenges that they face into opportunities? Klaus Petersen, Director Automotive & Lithium Battery Industries, Mitsubishi Electric, explores the factors holding battery manufacturers back and how they can be overcome. We report here a long essay on this subject.

The future of the lithium-ion battery sector is incredibly bright. Over the approximately three decades since the technology made the transition from labs to production lines it’s gone from strength to strength and now stands poised to become a key factor in a global transportation revolution. As demands grow, so does the pressure on manufacturers. How can they effectively scale-up and improve their operations to turn the challenges that they face into opportunities? Klaus Petersen, Director Automotive & Lithium Battery Industries, Factory Automation EMEA at Mitsubishi Electric, explores the factors holding battery manufacturers back and how they can be overcome.

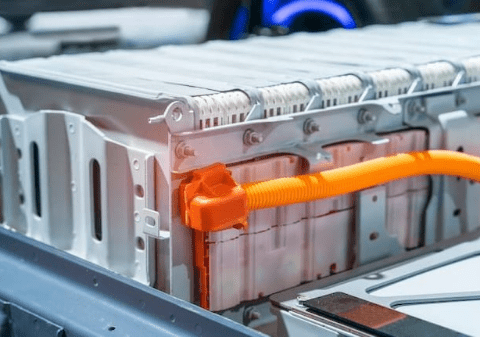

Lithium-ion batteries require expensive raw materials and undergo a particularly complex production process with high scrappage rates. If manufacturers are going to be able to scale up their operations and help EVs take their place at the heart of the transport sector, they need every possible advantage they can find.

One approach that can help deliver this advantage is digitalisation – the implementation of digital technologies to harvest and process the vast quantities of data produced in modern manufacturing, delivering insights to realise tangible benefits to the production process.

Meeting rising demand

It is very hard to overstate just how dramatically the lithium-ion battery sector is set to grow over the coming decade. Rising demand from the EV sector has already helped the global market expand from around US$40 billion in 2018 to more than US$60 billion in 2022, and this growth rate is only projected to accelerate. By the end of the decade, it’s predicted that the market will be worth more than a quarter of a trillion dollars.

However, the sheer scale of this expansion presents several challenges. Not only is competition set to grow incredibly fiercely, but the raw materials used to create lithium-ion batteries are set to become even more expensive as demand rises. Lithium, cobalt and nickel all need to be mined and processed before being used in manufacturing, and the IEA predicts that the total demand for the minerals required for EV production will increase 30-fold between 2020 and 2040.

If the manufacturing sector is going to meet the increasing demand for EVs, it’s vital that production is made as efficient as possible. However, one of the key challenges currently facing the battery sector is implementing effective quality control and tackling high wastage rates.

Despite being made from valuable materials, a typical plant can expect to see about 10% of finished products fall short of the minimum standards and end up as scrap. In many cases, this rate can climb as high as 30%. This high level of scrappage is incredibly expensive, and is one of the reasons why the battery typically represents up to 60% of the total cost of an EV. This isn’t due to carelessness or irresponsible behaviour on behalf of manufacturers. Rather, it is because the manufacturing process itself makes it extremely hard to implement traditional quality control measures.

The challenges of lithium-ion battery manufacturing

Lithium-ion battery manufacturing begins with the creation of ribbons (or foils) of metal – copper for the anode and aluminum for the cathode. The size of these ribbons can vary widely, depending on the design and specifications of the batteries being produced, but they are typically several hundred meters long – often stretching over a kilometre at larger manufacturing sites – and anywhere from a few centimeters to over a meter wide.

To turn them into batteries, the ribbons are coated in a thin film of active material slurries. The cathode typically uses materials such as lithium cobalt oxide, lithium iron phosphate, or other lithium metal oxides, while the anode is coated with graphite or silicon-based materials.

Regardless of the materials used, the thickness of these coatings has a major impact on the finished battery’s energy capacity and ion transport efficiency. Thicker coatings can store more active material, potentially increasing the battery’s overall energy storage capacity. However, this benefit comes with a trade-off, as overly thick coatings may impede the movement of lithium ions between the electrodes, reducing the battery’s charging and discharging speeds.

This balance between thickness for increased energy storage and the need for efficient ion transport is critical, as it directly impacts the battery’s performance, especially in EV applications that demand rapid energy delivery. If a coating is too thick or too thin, large sections of a ribbon may not be suitable for use in a finished product. Though the ideal thickness will vary depending on a manufacturer’s exact requirements, cathode coatings are typically in the range of 100 to 200 μm while anode coatings tend to be slightly thinner, usually around 70 to 120 μm. This is, coincidentally, roughly the range of thickness expected from a human hair.

Unsurprisingly, maintaining a consistent film this thin across an area measuring up to hundreds of square meters is incredibly challenging. Dozens of factors might impact the thickness of the finished product, ranging from the temperature of the film to the humidity inside the plant. Making sense of this complex, constantly changing data is almost impossible for conventional manufacturing setups. However, this is where the correct implementation of digital manufacturing technologies can help companies excel.

Mitsubishi: from raw data to results

Modern manufacturing lines are equipped with a vast array of sensors, generating an enormous volume of data. When this data is analysed effectively, it can be used to make significant improvements in the manufacturing process.

One common application is predictive maintenance. For instance, by analysing data trends, it’s possible to predict when a machine will require targeted maintenance based on the drive drawing slightly more current than usual, or an increase in amplitude of oscillations. This allows operators to deal with the issue long before it starts causing actual problems, preventing unexpected downtime and enhancing efficiency.

Companies can use this same principle to improve the state of lithium-ion battery manufacturing, not just by introducing predictive maintenance, but by working out what factors correlate with cell quality. This can determine which parameters can be controlled to achieve high-quality cells, improving the value of functional batteries and reducing the amount of materials that have to be scrapped.

Mitsubishi Electric has already applied this knowledge to real-world lithium-ion battery production lines, with impressive results. The team focused on the issue of inconsistent film thickness and collected data from 127 different parameters to determine which might be related. With the help of Mitsubishi Electric’s AI-driven MELSOFT MaiLab solution, they found that four were strongly correlated with variations in coating thickness – tension, coating pressure, over temperature, distance from coating opening.

Equipped with this valuable information, the team created a diagnostic rule to detect thickness. They then combined this with industrial automation technology, such as tension controllers, to carefully monitor and modify the parameters to ensure that as much of the ribbon would meet quality standards as possible.

Implementing a digital future: Mitsubishi tools

Implementing the tools, technology and expertise required for a digital manufacturing line isn’t necessarily a complex procedure, nor is it a binary, everything or nothing change that needs to be introduced across an entire production line in one go. However, it is a change that needs to be approached carefully. A successful implementation requires more than just buying the appropriate equipment. It must be addressed from two angles at the same time – technical and operational.

On the technical side, a manufacturer needs access to the right tools. This means ensuring that all machines and sensors have excellent connectivity and are linked to a high-quality data hub using advanced industrial networking solutions. Solutions like the CC-Link IE TSN network and MELIPC industrial computers can enable high-fidelity sampling, which is a must for working with materials as complex and changeable as lithium-ion batteries.

Beyond this, it’s important to invest in excellent visualization and correlation tools, such as those included in MaiLab and the ICONICS GENESIS64 suite. These will allow experts to unlock the insights hidden in any data and enable AI-powered algorithms to churn through masses of information and uncover correlations no human would have ever spotted.

A digital twin tool such as Mitsubishi Electric’s MELSOFT Gemini allows manufacturers to create a virtual replica of the process and trial any changes. However, it’s important not to get caught up in making a digital twin too complicated, especially during the early stages of a company’s digital journey. There’s very little point in trying to model an entire factory when you’re only really interested in one piece of machinery.

On an operational level, digitalisation in lithium-ion battery manufacturing starts with laying a solid operational foundation, essential for harnessing the full potential of new technologies.

Rather than a sweeping overhaul, manufacturers should adopt a gradual approach, initiating pilot projects targeted at specific areas of their operations. These projects serve as a practical first step, helping teams become familiar with the new tools and processes in a manageable context, addressing any issues on a smaller scale, and demonstrating the tangible benefits of digitalisation.

Pilot projects with clear, measurable objectives offer a strategic way to showcase quick wins, securing buy-in from stakeholders and paving the way for broader implementation. This methodical approach allows for the smooth integration of digital manufacturing technologies, reducing risks and enhancing the efficiency and quality of the manufacturing process. By starting small and scaling up based on successes, manufacturers can ensure a more effective transition to digital manufacturing, positioning themselves to meet the evolving demands of the battery market.

Turning challenges into opportunities

The lithium-ion battery sector faces incredible opportunities, but also huge challenges. As the demand for EVs escalates, scaling up production requires not just strategic planning but also an embrace of technology and data to navigate these complexities efficiently.

Here, digitalisation offers a clear path forward. It enables real-time monitoring and analytics, improving decision-making and product quality while reducing waste. The transition towards digitalised manufacturing demands investment and a shift in mindset but promises tangible returns. As the lithium-ion battery industry evolves, embracing digitalisation is not merely an option for those aiming to lead in the sustainable energy transition, but a necessity.

While digitalisation is often obscured by a cloud of jargon and business-speak – ‘Industry 4.0’, ‘smart manufacturing’, ‘Internet of Things,’ etc. – the reality is simple. The heart of digitalisation lies in transforming the analogue into the digital, and then applying engineering knowledge and expertise to deliver improved and optimised processes. It doesn’t need to be any more complicated than that.