Liebherr and the new LiGO injection systems for alternative fuels

With LiGO injection systems, the Liebherr components product segment introduces innovative injection solutions for climate-friendly fuels, such as hydrogen, methanol, ethanol and ammonia.

With LiGO injection systems, the Liebherr components product segment is launching an innovative product family specifically tailored to the demands of the mobility transition. The platform consolidates all new injection solutions for climate-friendly fuels under one roof. Thereby, LiGO represents Liebherr’s renowned quality and technological excellence. The “Li” symbolises Liebherr’s tradition and reliability, while “GO” stands for progress – towards sustainable, future-ready propulsion concepts.

Liebherr LiGO injection systems are the answer to the increasing importance of climate-friendly fuels, such as hydrogen, methanol, ethanol and ammonia. With a broad portfolio, the product family offers solutions for single-fuel and dual-fuel applications. The existing engines also allow retrofitting to meet the requirements of various applications.

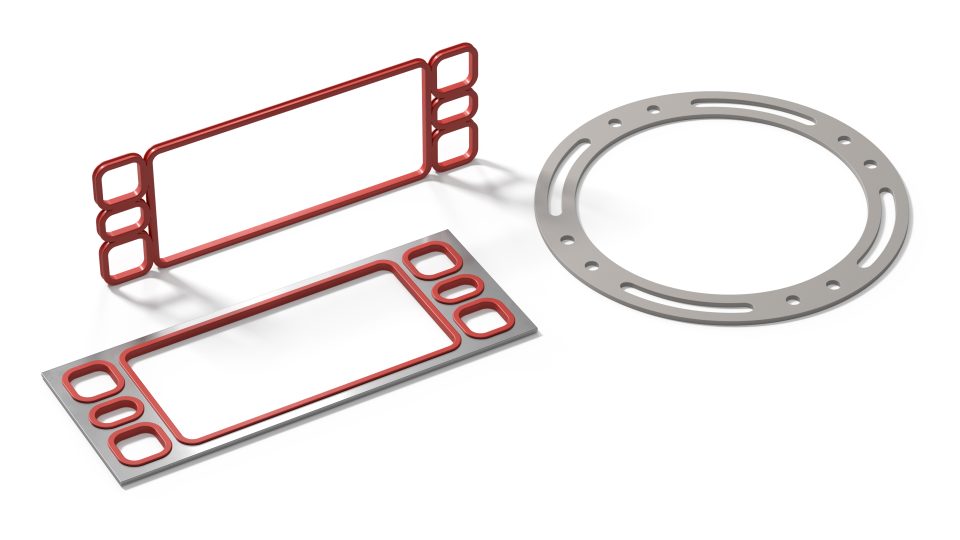

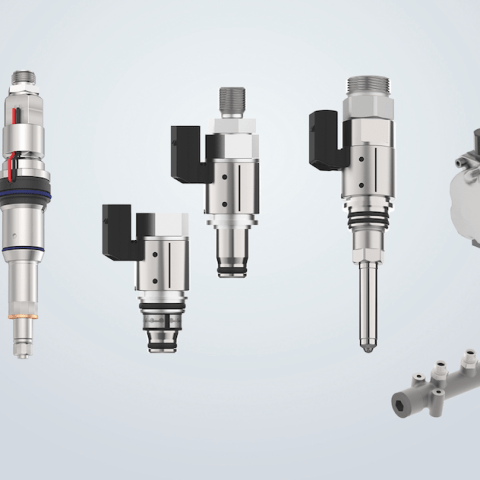

LiGO offers port fuel and direct injection systems with a standardised platform design. This enables efficiency and flexibility in upgrading engines for different combustion concepts, since fewer different parts are used, which simplifies production and maintenance. A highlight of the portfolio is the single-fuel solutions with 100% hydrogen for spark-ignited combustion concepts. The LPI hydrogen injector for port fuel injection and the LDI hydrogen injector for direct injection operate with different injection pressures and offer performance characteristics similar to those of diesel engines.

The LiGO family for hydrogen includes the LPI injector specially designed for port fuel injection at pressures from 2 to 15 bar. It made its debut in an innovative Liebherr wheel loader prototype, the L 566 H, which was presented for the first time in 2024. Another member of the family is the LDI injector, developed for direct injection with pressures of 5 to 30 bar. It is ideal for high-performance applications with a driving behaviour similar to diesel engines. Finally, the LiGO family counts the H2 rail and the LRM control block, which are used for the stabilisation of pressure and fuel quantity control. On top, they are equipped with comprehensive diagnostic and safety functions. The modular platform design allows for easy adaptation of components to different engine concepts and applications.

LiGo for alternative fuels

For liquid alternative fuels such as ammonia, methanol and ethanol, LiGO injection systems offer solutions that retrofit existing diesel engines or enable new engine concepts. The port fuel injector for liquid fuels is based on the design of the hydrogen injector. With its high flow rate, it is particularly suitable for high-performance engines. The portfolio is complemented by an independent, electrically driven fuel pump currently designed for methanol.

One of the members of the LiGO family for ammonia, ethanol and methanol is the LPI injector for liquid alternative fuels, which was developed on the basis of the hydrogen injector platform for the pressure range from 5 to 30 bar. The family also includes an electrically driven fuel pump that allows packaging independent of engine design.

Read also: Liebherr at Bauma 2025: new electric machines for off-highway applications