Liebherr at Bauma 2025: new electric machines for off-highway applications

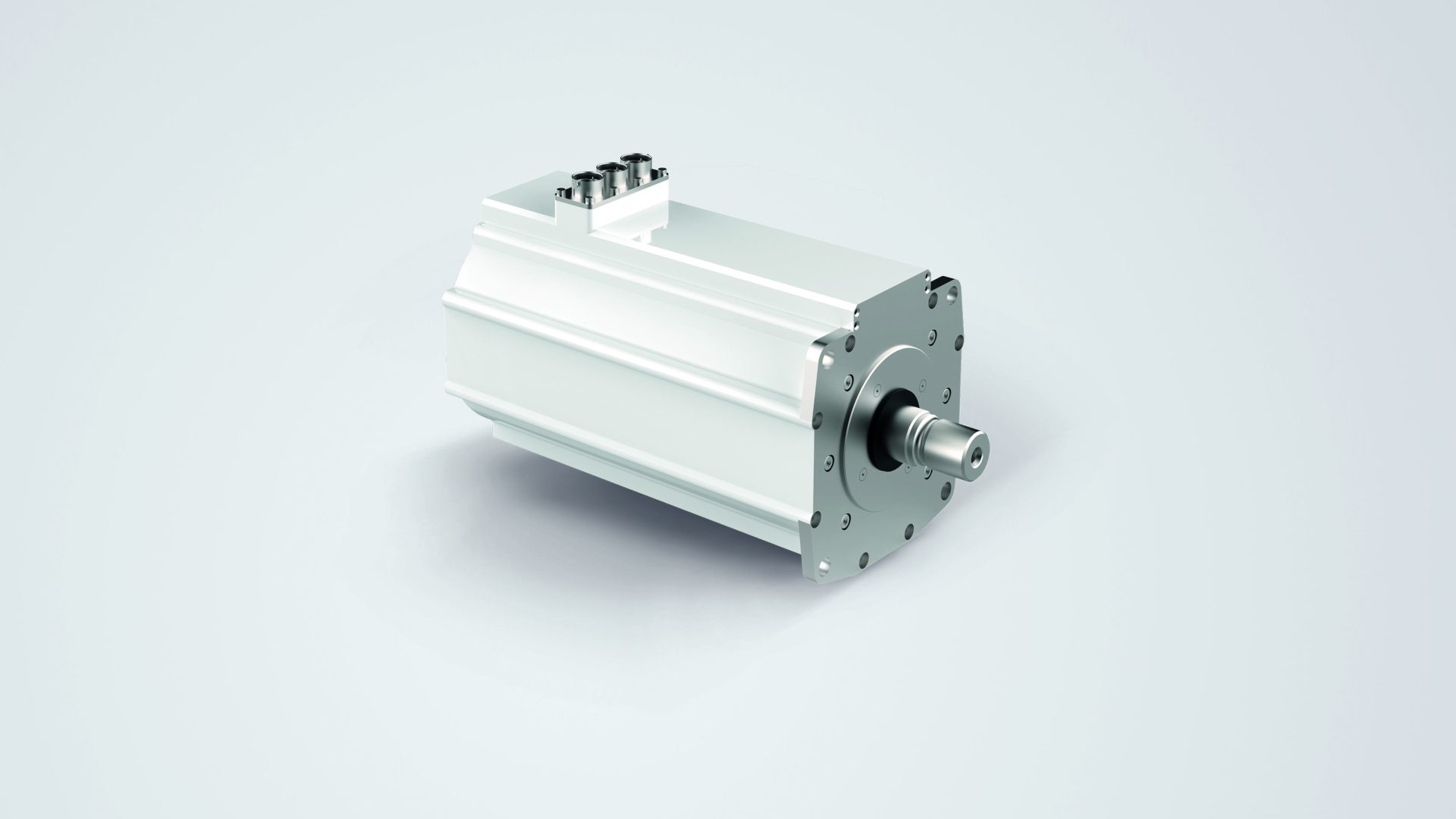

At Bauma 2025 we will see the newly developed electric machines by Liebherr for off-highway applications. With the same power density of hydraulic motors, they provide for a significantly higher efficiency of an application.

At Bauma 2025 we will see the newly developed electric machines by Liebherr for off-highway applications. With the same power density of hydraulic motors, they provide for a significantly higher efficiency of an application.

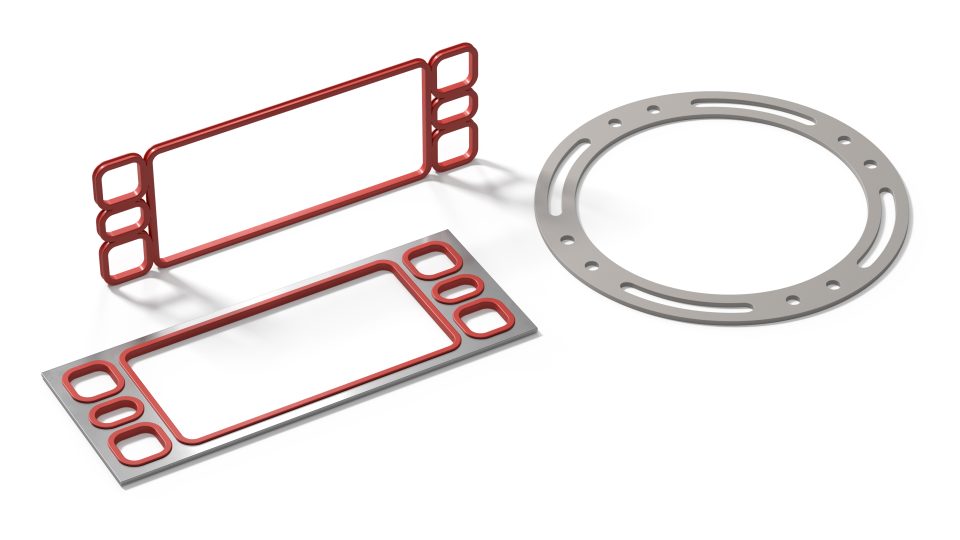

When it comes to mobile machinery, operational reliability, robustness, durability and efficiency along with compact designs have always played a vital role. Until now, hydraulic motors were able to offer a power density that met the high demands of mobile applications, such as excavators, wheel loaders and telehandlers. The new design of the permanent magnet machines now comes with the same power density, but without the effort and risks caused by the extensive piping systems of hydraulic.

The direct oil-cooled electric machine, which has been specially developed for battery and diesel-electric traction drives, enables quick and easy installation, as well as the electrification of existing hydraulic drive concepts. Thanks to moderate pressures in the cooling circuit, the risk of leaks is significantly lower, which results in higher safety. In addition, there is no further risk of emissions, contamination or accidents because of burst pipes. The permanent magnet machine is the sustainable alternative that makes applications future-proof.

The innovative design of the motor significantly reduces maintenance efforts. This results in less downtime and lower maintenance costs. In addition, the high torque in relation to the speed ensures a longer service life of the machine and an increase in the MTBF (mean time between failures) in the system due to the reduced number of gear stages. Liebherr’s permanent magnet machines are ideal for mobile applications, in which compact installation space as well as the reduction of emissions and contamination are crucial.

With an efficiency of 94 to 96 %, a permanent magnet machine is far more effective than a hydraulic motor (approx. 50 %), and therefore consumes significantly less energy. Even though the acquisition costs of an electric motor are generally higher than those of a hydraulic one, the new electric machines prove to be more cost-effective over the entire service life of an application, when the operating costs are taken into account.

Read also: Bauma 2025, alternative drives to decarbonize the construction site