Liebherr solutions at bauma 2022

At bauma 2022 (24-30 October), Liebherr will offer the visitors an insight into the world of components alongside the latest developments in construction machinery, cranes, material handling and mining.

At bauma 2022 (24-30 October), Liebherr will offer the visitors an insight into the world of components alongside the latest developments in construction machinery, cranes, material handling and mining.

Liebherr: digital solutions at bauma

In order to optimally master the associated challenges, Liebherr offers comprehensive digital solutions to increase the performance, reliability and security of customer applications. The camera-monitor systems and surround vision solutions in the LiXplore product family are based on digital camera technology. The assistance systems feature higher resolution and, therefore, a more detailed view of the working environment outside the cab. For drivers of a mobile machine this is of real benefit in terms of efficiency and work safety.

The integrated digital wear measurement system for optimum monitoring of slewing bearings, Bearing Clearance Monitoring (BCM), the force measurement sensor for hydraulic cylinders and digital condition monitoring for combustion engines also play a role in ensuring improved safety, higher performance and longer machine service life.

Alternative drive concepts

The heterogeneous fields of application typical of construction machinery require the most suitable form of drive for the specific application and site, in order to ensure the greatest possible machine efficiency.

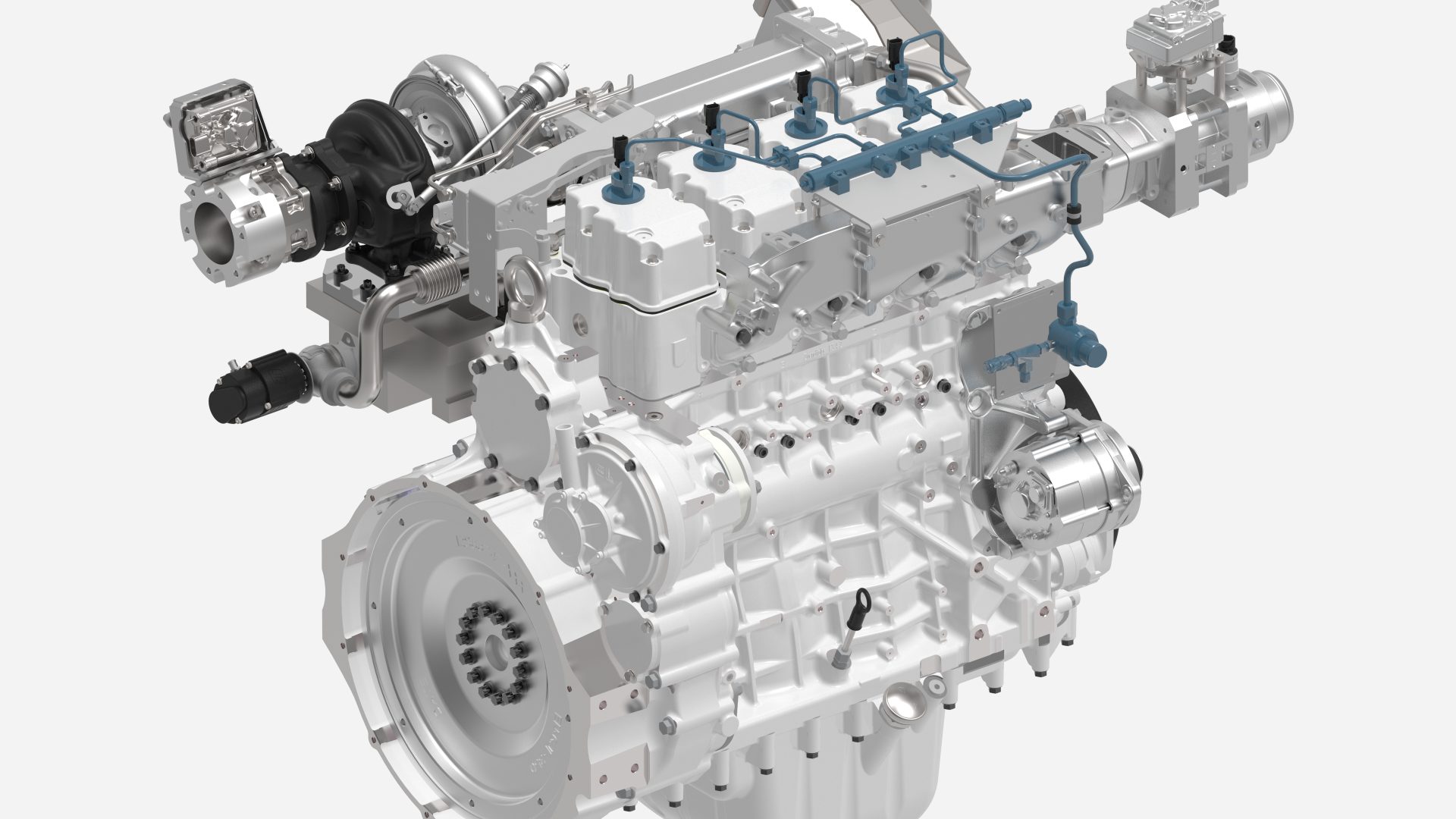

With this in mind, Liebherr offers customers engines with high efficiency and very low NOx emissions with the same service life and maintenance intervals as diesel engines. The first hydrogen engine ever built at Liebherr, the H964, ensures high performance and efficiency at competitive costs and high availability thanks to the large proportion of common parts.

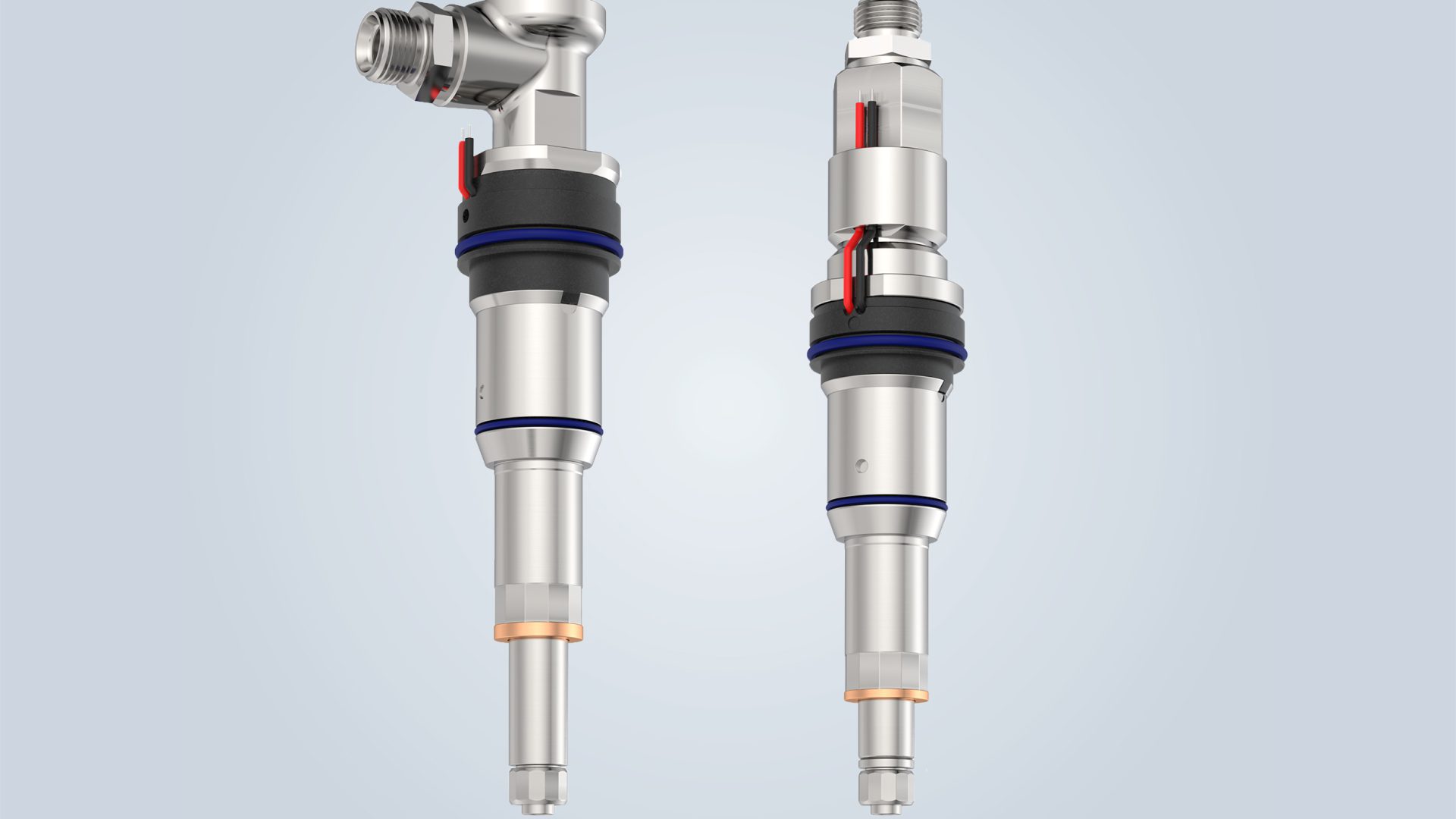

In response to the trend of decarbonisation, Liebherr enhances the internal combustion engine and offers various hydrogen injection solutions. The system approaches for port fuel injection (PFI) and direct injection (LPDI) are based on a common, scalable injector platform. A wide range of applications is possible for medium and heavy-duty engines, as well as large engines in the 7-100 litre displacement range.

To optimise the operating performance of hydrogen-powered commercial and construction vehicles, Liebherr is also developing electric turbochargers. Air compression provides a higher oxygen partial pressure and thus a higher power density.

In the future, Liebherr’s mobile energy storage systems will ensure locally emission-free operation of electrified or hybrid-powered construction sites. The challenge on fully electrified or hybrid-powered construction sites is operating machines at maximum power, charging all machines during break periods, or smoothing power peaks on sites with limited grid supply.

Innovative, efficient and open to technology into the future

Liebherr wishes to create solutions that meet both work and environmental requirements at all times, like the new online configurator for hydraulic cylinders. In future, all products in the standard series can be conveniently configured via the Liebherr website and downloaded as 3D models, for example. All cylinder variants can be requested directly and easily via the configurator – Liebherr ensures a response within one working day.

Hybrid cylinders as part of the fibre composite portfolio ensure greater effectiveness and efficiency of mobile and stationary applications. Thanks to the use of the lightweight components and the inherent weight savings, performance can be increased or fuel consumption reduced.

The axial piston hydraulics also offers flexibility in application. Thus, the LH30VO family with the nominal sizes of 28, 45 and 85 will be extended by the nominal size of 100. It is characterised in particular by a modular system of controllers and a high degree of flexibility for the drive-through concept. In addition, the rated size of 550 (also available as a double pump of 1,100 cm3) complements the selection of open circuit pumps. In the development of this rated size, the focus lied on robustness.

The newly developed combustion engine for off-road applications, the D976, is also suitable for individual customisation options. Its high power density, robust design and wide range of options make it perfect for the harshest environments and provide an ideal solution for a variety of industries and applications. Because the engine is compatible with hydrogenated vegetable oil (HVO), operators can reduce their emissions by up to 90% when filling up with the alternative fuel instead of diesel.