Mann-Filter for future filtration requirements

Driving concepts from Mann-Filter, Automechanika Mann+Hummel has decided to put into practice its decades of experience in the field of filtration to meet the new requirements of alternative vehicles. The group showed the new solutions at Automechanika 2018. «Regardless of which driving technology will prevail in the future, or even if the future will be based on […]

Driving concepts from Mann-Filter, Automechanika

Mann+Hummel has decided to put into practice its decades of experience in the field of filtration to meet the new requirements of alternative vehicles. The group showed the new solutions at Automechanika 2018. «Regardless of which driving technology will prevail in the future, or even if the future will be based on the coexistence between different technologies, the filters will still be used» said Uwe Hartmann, vice president of Marketing Automotive Aftermarket at Mann+Hummel. Below the group’s proposals regarding the innovation of filtration solutions.

Particulate filter for brake dust

Even in the case of electric vehicles, the wear of the brake disc and the bearing produces dust at each braking. A significant part of that dust consists of small particles that are harmful for human health and the environment due to their small size. The new particulate filter for brake dust proposed by Mann is able to reduce the particulate generated during braking by up to 80 percent.

Thanks to the robust housing located directly next to the brake caliper, the filter acts directly on the production point to prevent the release of fine dust into the environment, especially in situations like urban traffic that require frequent braking. The filter material is resistant to temperature and corrosion, thus allowing efficient filtration based on the different particle sizes.

Filtration of fine particles in movement

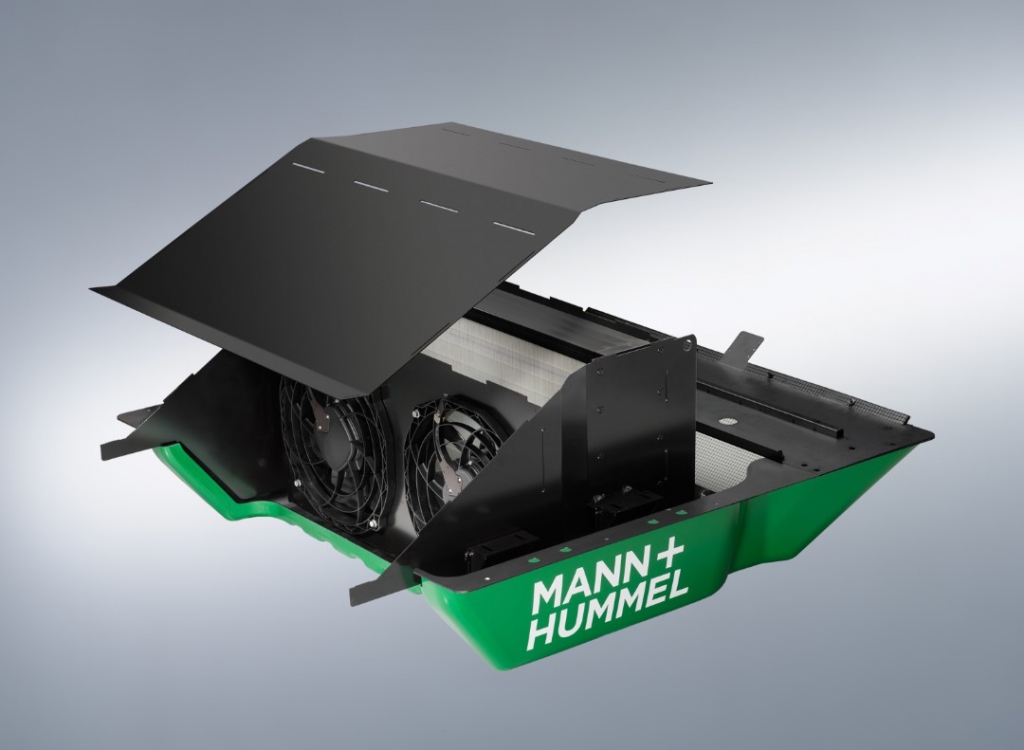

To reduce pollution caused by fine particles in urban concentrations, Mann+Hummel developed a fine dust filter, tested during field studies since the middle of last year.

For example, installed on the roof or at the bottom of a vehicle, the filter can remove fine dust from the air. The particularly low flow resistance of the filtering element used allows the maximum possible volume flow and a high separation capacity. For this purpose, the fans draw air from the environment to the filter, which means that vehicles can filter thin dust from the surrounding air even when the vehicle is stationary.

MADE IN GERMANY: FROM HANOVER TO FRANKFURT

Depending on the prevailing conditions, an electric vehicle can operate at neutral emissions through the use of a fine particle filter. As for the general balance of driving operations, this means: no carbon dioxide (CO2), no nitrogen oxide (NOx), no noise and no fine dust.

Filter for transmission fluids for E-axle

Where power electronics, electric motor and transmission are combined to form a so-called “E-axle“, this requires not only the cooling of the fluid, but also the lubrication.

The Mann+Hummel transmission fluid filter ensures clean oil for lubrication and cooling of the toothed wheels, and other components in the transmission, for vehicles with electric drive. The high efficiency filter, with a completely synthetic filter material, has a low differential pressure, high chemical and thermal resistance and it is designed to last over time. Thanks to the folding technology, a large amount of filter material can be installed in a very small space.

Battery ventilation device

Another important component for electric vehicles is the battery ventilation device, for which Mann+Hummel has already started mass production for purely electric hybrid vehicles. The core of this device, which is mounted on the battery compartment, is a gas-permeable membrane that ensures the necessary permanent compensation of the pressure between the battery system and the environment, retaining dust and water. For example, if an overpressure occurs due to a malfunction in the battery system, the device quickly relieves it to prevent the compartment from bursting.