NAWA improves materials

Nawa Technologies hits production milestone as manufacturing of nano-based energy storage material begins

NAWA Technologies knows that the quality of materials plays a crucial role in power density and energy storage capacity. The company revealed the start of manufacturing of Vertically Aligned Carbon Nanotube (VACNT) material.

NAWA and Vertically Aligned Carbon Nanotube

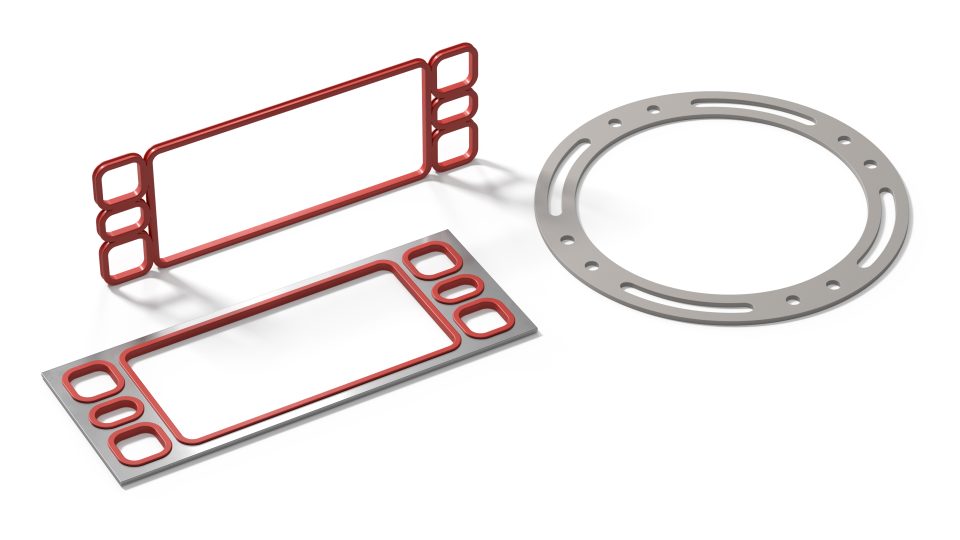

NAWA’s success demonstrates, for the first time, that VACNT can be grown simultaneously on both sides of a substrate – a process that is fully scale-able. Offering multiple global uses, NAWA’s key applications for VACNT include its Ultra Fast Carbon Electrode which brings a quantum leap in the performance of any battery, to its next-gen ultracapacitors, NAWACap, which boast up to five times more power capability than conventional technology, and its NAWAStitch advanced reinforced composite innovation. From a dedicated production line located at its Aix-en-Provence facility in southern France, NAWA’s initial production ramp-up demonstrates that, for the very first time, VACNT can be grown simultaneously and homogeneously on both sides of a substrate at Atmospheric Pressure using a Chemical Vapour Deposition (APCVD) process, in a roll-to-roll manner.

Over 200 micrometer

The process has demonstrated the ability to grow up to over 200 micrometer long VACNT double-sided simultaneously on a 30 cm wide aluminum foil, and to selectively grow VACNT on the foil, essential for revolutionary electrodes designs and production efficiency. This development process is just the start of a scale-up in terms of foil width and roll-to-roll productivity.

A highly flexible and modular manufacturing system, its specific design makes it very compact compared to conventional coating equipment resulting in a footprint in a factory environment that is minimized, while the highly-efficient process means that the production cost of NAWA’s VACNT material can achieve parity with that of a current electrode at future mass production levels.

Straight from NAWA headquarters

Pascal Boulanger, Founder, Chairman of the board, CTO and COO of NAWA Technologies said: ““We are delighted to announce that, today, a major milestone has been reached after only eight years, with the start of production of our Vertically Aligned Carbon Nanotube (VACNT) material. I would like to say thank you to our team, they are to be congratulated for achieving this fantastic goal and what a birthday cake made of 100 billion candles (VACNT) per cm2, as we pass our eighth birthday!”

Ulrik Grape, CEO, NAWA Technologies, said: “Based on the superb work carried out by our talented team and the support of our stakeholders, we have entered the first exciting industrialization phase and are on track to rapidly scale up with mass production set to begin in 2022. The potential for our VACNT innovation is massive in energy storage – from bringing about a quantum leap in the performance of electrodes in any battery system, to our next-gen ultracapacitors – and also in reinforced composites. What’s more, we are bringing this unique material to market in an environmentally friendly manner too.”