Alfa Laval fights Sox and NOx

PureSOx Connect brings customers further compliance security Alfa Laval tames the ‘bad’ chemistry upgrading the devices against oxidation. In a nutshell, scrubber vs sulphur and Egr vs nitrogen. PureSOx is the leading scrubber solution for meeting SOx emissions limits, including the 2020 global sulphur cap. With PureSOx Connect, a growing portfolio of data-driven services, PureSOx […]

PureSOx Connect brings customers further compliance security

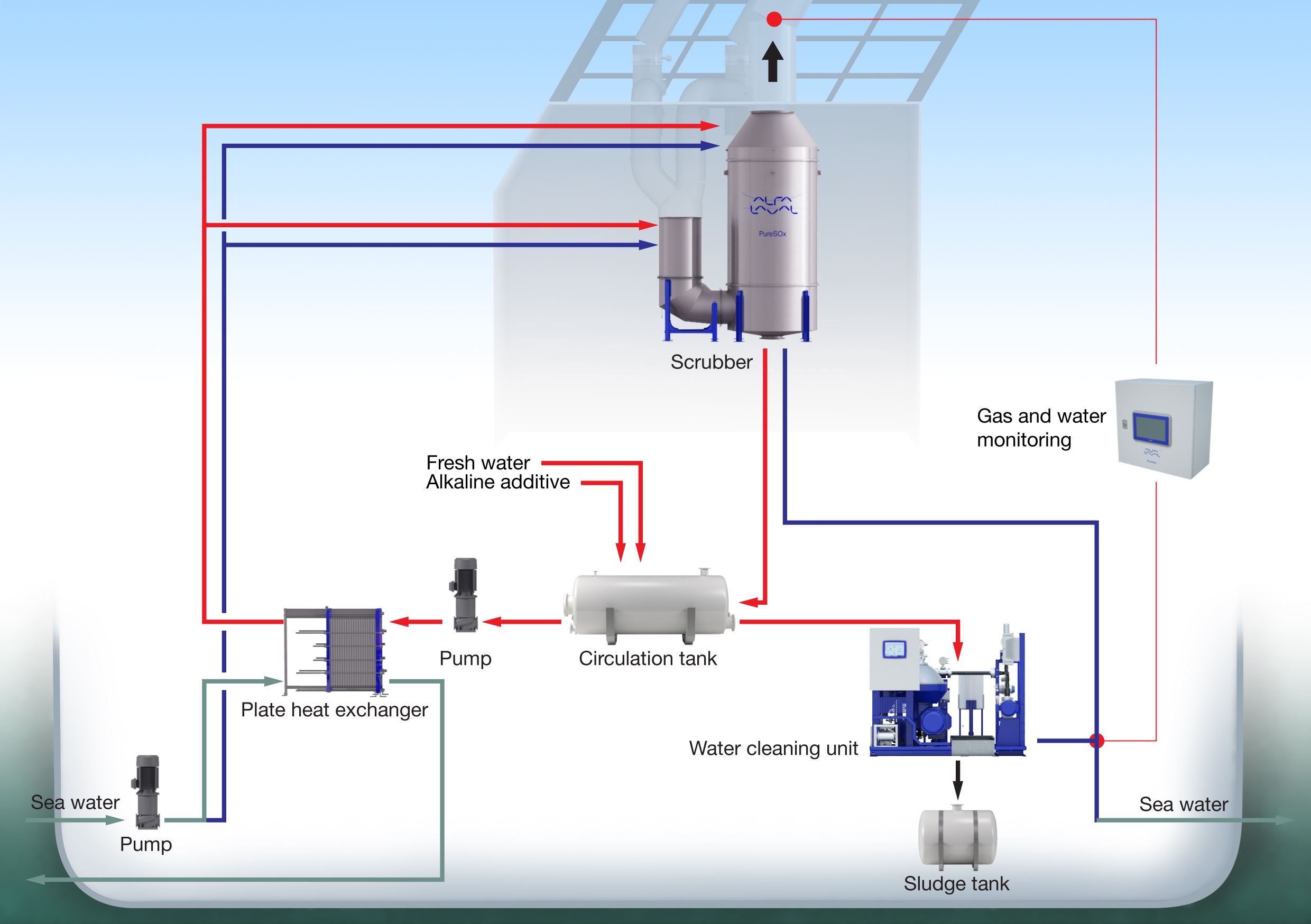

Alfa Laval tames the ‘bad’ chemistry upgrading the devices against oxidation. In a nutshell, scrubber vs sulphur and Egr vs nitrogen. PureSOx is the leading scrubber solution for meeting SOx emissions limits, including the 2020 global sulphur cap. With PureSOx Connect, a growing portfolio of data-driven services, PureSOx becomes even more comprehensive and future-proof.

«PureSOx Connect provides a wide range of benefits for PureSOx customers, whether they have a system installed on a single vessel or installations throughout their fleet», says Olaf Van Heerikhuizen, Manager Service Gas Systems at Alfa Laval. «PureSOx Connect can save time for crews today, plus help customers predict maintenance needs and reduce operating costs over time».

The services in the PureSOx Connect portfolio are built on the Alfa Laval Remote Emission Monitor (ALREM), a data reporting and storage device. The ALREM is part of all new PureSOx orders and available as a retrofit package.

«Connectivity is not something reserved for new PureSOx installations,» says Van Heerikhuizen. «The technology is readily available and easy to incorporate into existing PureSOx systems. The ALREM itself is only the foundation. It’s the PureSOx Connect services that really make the difference for customers, drawing on the diagnostic and operational data that the ALREM provides».

The most basic service, creating user-friendly compliance reports for direct handover to authorities, is available to all PureSOx customers through the Alfa Laval Touch Control system on board. But far greater possibilities are offered via the PureSOx Connect online portal, which is available on a subscription basis for a monthly fee. Using the portal, customers can review the data for a single vessel or their entire fleet at once – from anywhere in the world.

Greater EGR economy at different fuel sulphur levels

Alfa Laval PureNOx technology has long been the choice for water treatment in Exhaust Gas Recirculation (EGR), one of the main strategies for Tier III NOx compliance. Soon it will be channelled into two differentiated systems, PureNOx LS and PureNOx HS, optimized according to fuel sulphur level and the updated specifications of engine manufacturer MAN Energy Solutions.

«By taking advantage of the new EGR specifications, we will provide optimized and more compact water treatment systems that lead to more cost-efficient EGR,» says Ayla Körlof, Global Business Manager, Alfa Laval PureNOx. «The centrifugal separator module, which will be identical for PureNOx LS and PureNOx HS, will be 50% smaller than that of today’s PureNOx Prime.»

«When PureNOx HS is used with a closed-loop or hybrid scrubber system, the EGR bleed-off water will be processed by the SOx system’s own water cleaning unit,» says Körlof. «This means added peace of mind for customers who choose EGR with PureNOx and exhaust gas cleaning with Alfa Laval PureSOx. Not only is the PureSOx water cleaning unit the most effective on the market, customers will get a complete, tested and approved setup with smoothly cooperating systems from a single supplier.»

A further benefit of both PureNOx LS and PureNOx HS will be the ability to support operation in Eco EGR mode. Eco EGR is an additional engine mode in which EGR is used for Tier II as well as Tier III compliance. When Eco EGR is employed for Tier II, the EGR system will both reduce NOx formation and result in substantial fuel savings.

«For Eco EGR mode to work, the water treatment system must be able to operate continuously,» says Körlof. «PureNOx LS and PureNOx HS have been tested and proven in round-the-clock operating conditions, which means customers will have reliable access to Tier II fuel savings.»

Alfa Laval is optimizing the entire fuel line to address 2020 fuel challenges

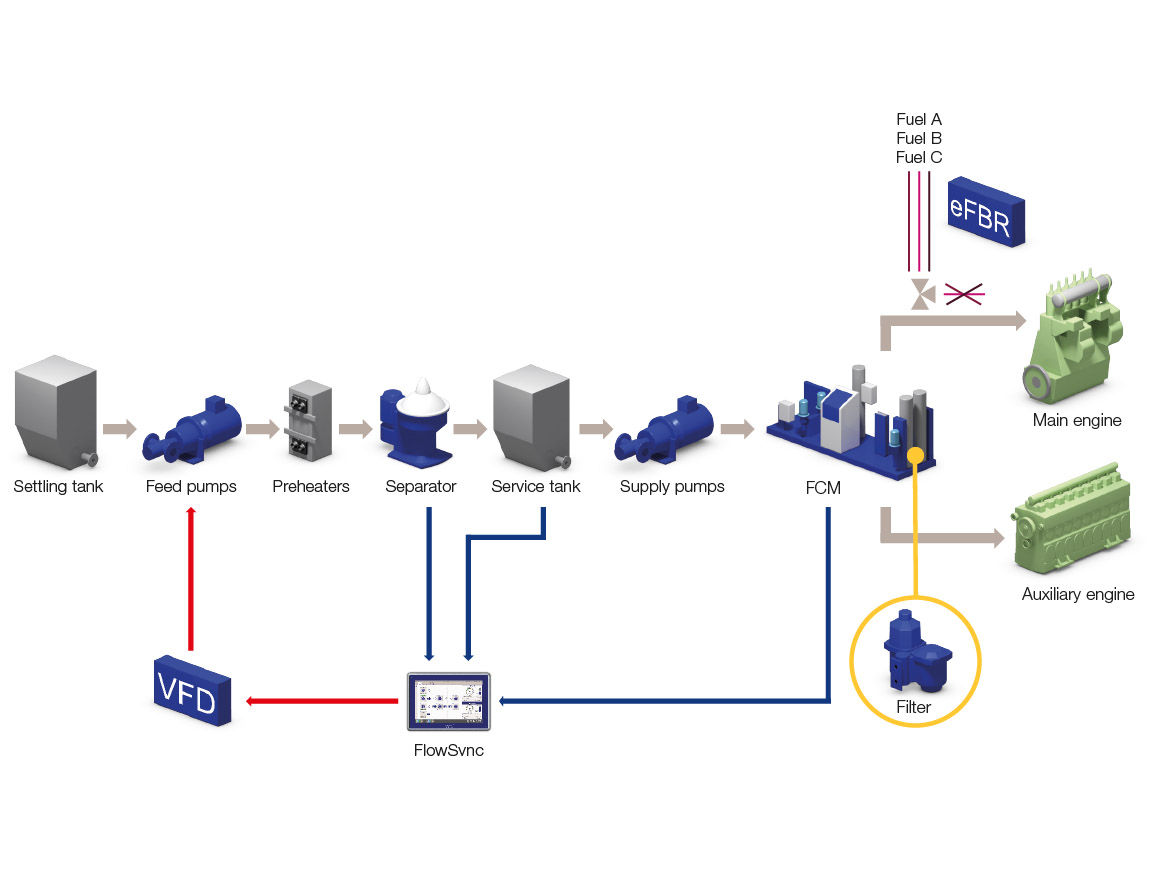

«There will be many options for compliance and every vessel will have to choose the route that makes most sense for their operation,» explains Serdar Sengun, Global Sales Manager Marine Separation, Alfa Laval. «No matter what customers choose, it will have dramatic implications for the fuel line. But Alfa Laval is taking a complete and forward-thinking approach to fuel line optimization.»

A number of new fuels and fuel blends have already entered the market, and more are likely to appear once the global sulphur cap is in place.

«As refineries recalibrate for lower sulphur content, we also anticipate a continued increase in the proportion of cat fines in marine fuel oils,» adds Sengun. «Already, we have seen a huge rise in cat fines, which cause major problems if not separated from the fuel before it reaches the engine.»

«Matching the separator feed to engine load is critical to achieving the highest efficiency and engine protection, as field tests have clearly shown,» says Sengun. «After separation, matching the fuel to the maker’s specifications is critical for the engine, its injection systems and the safety of the vessel. All of these processes have to occur smoothly and safely, no matter what fuel is used.»

«As the market’s only supplier offering solutions and expertise for the entire fuel line, we are helping customers adapt today to the changes that are coming tomorrow,» says Sengun. «No matter how vessels decide to meet the global cap, Alfa Laval technology will bring them the protection, efficiency and performance they need.»