Nuvola SafeCoat ™ Direct Deposition Separator

Nuvola SafeCoat Direct Deposition Separator product is a drop-in solution for lithium-ion batteries that replaces conventional film separators

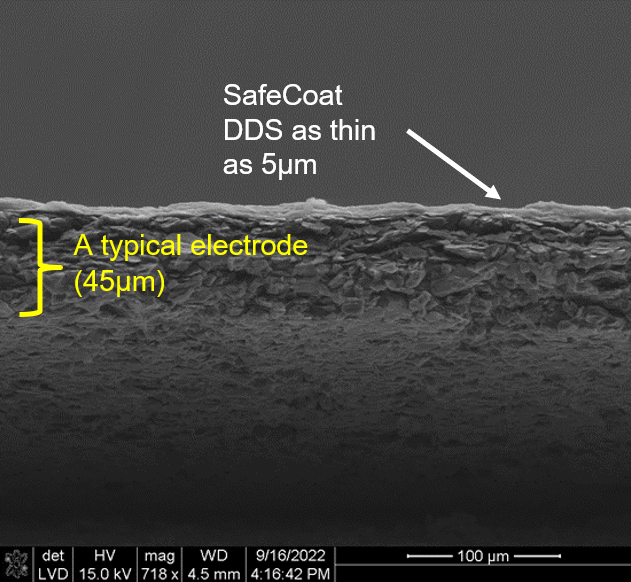

The SafeCoat ™ Direct Deposition Separator (DDS) product by Nuvola Technologies is a drop-in solution for lithium-ion batteries (LIB) that replaces conventional film separators with a porous polymer coating sprayed directly on the entire electrode surface. SafeCoat DDS is compatible with manufacturing techniques used in LIB factories worldwide. The Nuvola separator is battery chemistry agnostic and designed to work with conventional and emerging electrode chemistries. Porosity, wettability, ionic conductivity, temperature range, and other key specifications are highly competitive with premium separator materials in the market today. Unlike traditional film separator material, with SafeCoat DDS, battery performance-critical characteristics are each precisely tuned to the manufacturer’s battery chemistry, electrode material, and application requirements.

Electrification and Nuvola SafeCoat according to GlobalData

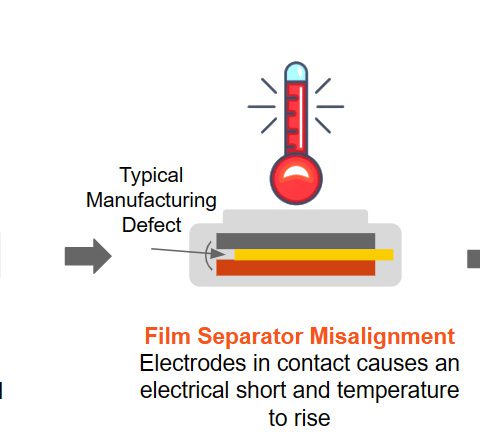

Nuvola Technology’s SafeCoat Direct Deposition Separator is a product designed to address hazards associated with thermal runaways in batteries. Thermal runaways can occur when batteries reach extremely high temperatures, leading to violent cell venting, smoke, and even fire. These events are not only dangerous but can also cause damage to the batteries and surrounding equipment. The SafeCoat Direct Deposition Separator aims to prevent internal shorts, thermal runaways, and fires in batteries. It achieves this by acting as a barrier between the battery’s positive and negative electrodes, thereby minimizing the risk of short circuits. Short circuits can cause rapid and uncontrolled energy release, leading to the hazards mentioned earlier. By using this separator technology, Nuvola Technology aims to enhance battery safety and reliability, making batteries safer for various applications, including electric vehicles, consumer electronics, and renewable energy storage systems.

Rupayan Chakraborty, Automotive Analyst at GlobalData

“However, producers confront a few hazards in exploiting these opportunities, such as thermal runaways in batteries that arise at extremely high temperatures, violent cell venting, smoke, and fire. To address this issue, Nuvola Technology has introduced a new product, SafeCoat Direct Deposition Separator, that aids in the prevention of internal shorts, thermal runaways, and fires in batteries. Looking at the situation, it is apparent that this new product will undoubtedly influence the actions of battery makers. The product is claimed to increase manufacturing yield as well as safety. So, if the product passes the battery makers’ trial tests, we can expect new batteries with this novel separator. However, from a manufacturing standpoint, the problem is that if this product raises battery-making costs, it will be ineffective. However, if it provides cost leverage to the battery makers, it will undoubtedly conquer the market and replace existing traditional separators. As per the estimates by GlobalData, the electric vehicle (EV) market, which includes BEVs and hybrid vehicles (HEVs), is expected to reach 62.74 million units by 2030, with a compound annual growth rate (CAGR) of 16% from 2022 to 2030. Approximately, 5000-9000 battery cells are required for EV batteries depending on battery capacity. As its new product will be used as a cell separator, Nuvola Technology has a big chance of becoming a market leader in battery material manufacturing, if they can reduce manufacturing costs as well.”