OXON Technologies launches products that cut emissions in combustion engines

When these OXON products are blended into liquid fuels at refineries, central fueling stations or vehicle tanks, they modify the fuels to accelerate and transform combustion.

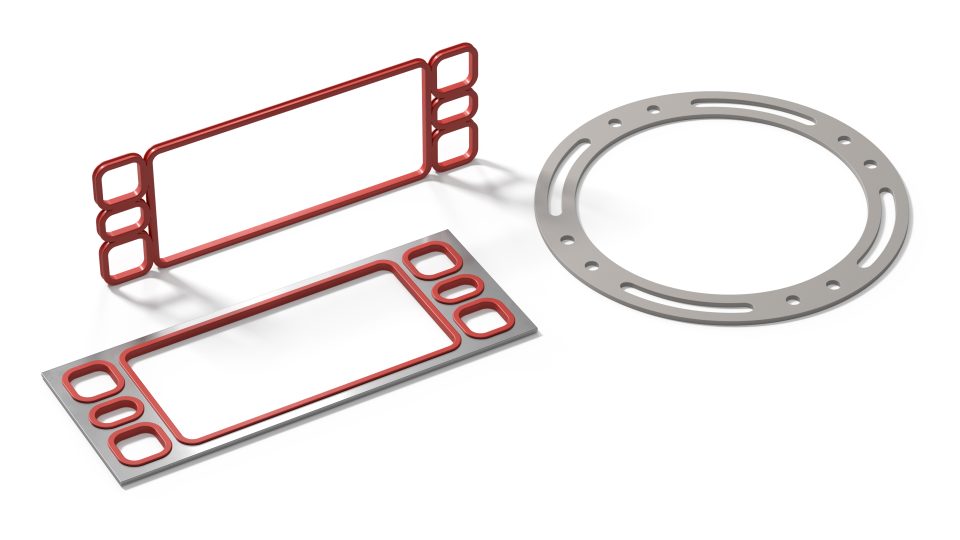

OXON Technologies launches OXON Drive and OXON Build products based on its patented OXONtech process that dramatically cuts emissions and fuel consumption for combustion engines. By reducing the activation energy required for combustion in liquid fuels, OXONtech products enable cleaner and more efficient combustion directly cutting carbon emissions by over 20% and fuel consumption by over 10%.

With tens of thousands of vehicles already using OXONtech products, the firm is now scaling production to meet demand globally. OXONtech is a patented method for inducing permanent dipoles (molecular charges) into proprietary OXON products. When these OXON products are blended into liquid fuels at refineries, central fueling stations or vehicle tanks, they modify the fuels to accelerate and transform combustion.

How it works

OXON products introduce nano-micelles (charged micro-clusters of organic molecules) that disperse amongst the hydrocarbon molecules of fuel. OXON nano-micelles contribute free radical particles that create cascade reactions with lower energy activation barriers thus promoting faster combustion and reducing fuel consumption. OXON nano-micelles also create complexes with oxygen. During combustion, these minimize heat absorbing oxygen-nitrogen collisions, thus reducing NOx emissions which are harmful to air quality and human health.

Addressing the environmental impact of internal combustion engines, OXONtech powered fuels have a transformative effect on the emissions profile of engines which emit up to 90% less particulate matter, 60% less NOx emissions, and 21% less CO2e emissions.

OXON products are easily integrated into existing fleet fueling operations. With over ten million hours of run time globally in 2024, OXON customers have displayed an average of 10% less fuel consumption and 97% less engine downtime from emissions faults when using OXON products.

Now scaling to meet global demand, OXON Technologies is currently supporting fleets that operate over 260,000 vehicles across the United States, Europe, and Africa in sectors including logistics, commuter transportation, mining, and construction.

One customer, NYSE listed Sterling Infrastructure Inc.’s portfolio businesses Petillo, has used OXONBuild on 330 heavy vehicles in its fleet and demonstrated a 10.5% average fuel reduction over the course of 2024. Other customers include some of the world’s largest transport and construction fleets.

Chief Executive of OXON Technologies, Andrew Lowenstein said: “We have created the building block for a new generation of cleaner fuels. Our patented technology modifies hydrocarbon fuels at the molecular level to enhance combustion, and our drop-in products are already transforming the role of internal combustion engines in the mix for decarbonization, efficiency improvement and fleet optimization. Once broadly adopted, OXON products each year could prevent 1.7 bn tons of carbon from being emitted across the globe, reduce spending on fossil fuels by $525 bn and contribute towards saving millions of lives currently lost to fine-particulate matter (PM2.5) & NOx pollution.”