Parker Prädifa unveils sealing solutions for safety of electrolyzers and fuel cells

The Prädifa Technology Division of Parker Hannifin has developed a wide range of sealing solutions tailored to the special requirements of electrolyzers and fuel cells – especially to the bipolar plates used in the cell stacks.

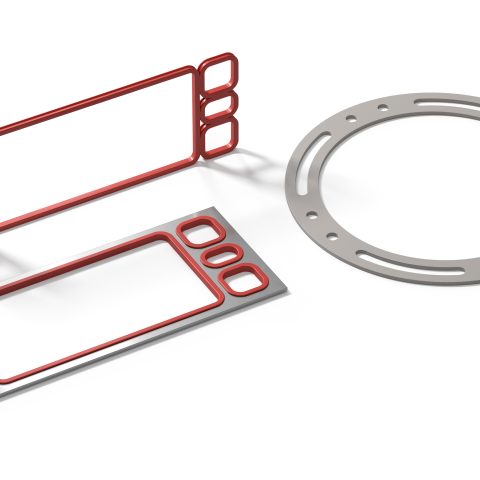

The Prädifa Technology Division of Parker Hannifin has developed a wide range of sealing solutions tailored to the special requirements of electrolyzers and fuel cells – especially to the bipolar plates used in the cell stacks. The portfolio extends from rubber frame seals to injected composite seals to PTFE seals that are available even in XXL dimensions.

Electrolyzers and fuel cells play a key role regarding the sustainable production and use of hydrogen. They are systems that are closely related to each other in terms of technology. Their composition and functional principle are basically similar but the functional principle of a fuel cell is inverse to that of an electrolyzer. Electrolyzers and fuel cells can differ in terms of size, cell chemistry, and operating parameters, and partly entail different requirements, depending on their technology. Irrespective of the specific technical design, the stack that is responsible for the chemical reaction is always central to the system. It consists of various components including – among other things – the electrochemical heart of the fuel cell or electrolyzer: the membrane electrode assembly (MEA).

In turn, the bipolar plates are a central element of the stack. They serve as connecting elements between the individual cells and enable the transportation of gases and liquids between the electrodes. In addition to gas distribution and cooling of the stack, they are responsible for sealing the stack against the outside. Reliable sealing of bipolar plates poses one of the greatest challenges to designing fuel cell or electrolyzer systems. Inadequate sealing can lead to gas leaks or electrolyte loss, which may impair system performance, or to safety issues. The seals used are crucial for efficiency and safety of the total system and both reliable sealing against the outside and effective separation of the process gases within the system are essential to optimal performance of fuel cells and electrolyzers.

Aside from suitable materials, that calls for a simple, reliably operating, and easy to install seal design enabling cost-efficient and reliable mass production. Parker Prädifa has developed an extensive portfolio of various sealing solutions in a wide variety of sizes and shapes for that purpose. It extends from elastomer frame seals to composite solutions with seals that are connected to carrier frames or directly to the bipolar plate or other components of the stack (e.g., mounting frames, gas distribution structures, or membranes). For harsh application conditions and particularly high service life requirements, PTFE sealing solutions are available as well.

Read also: Parker announces new test rig for fuel cell technology