Rotary Power for the next generation of multi-terrain vehicles

Rotary Power has collaborated with Agile Vehicle Technologies to develop a motor for the first of its kind, all-terrain vehicle

How can the roughest terrain be tackled without jeopardizing the powertrain? (Here Aidro and additive manufacturing). According to Rotary Power. “Five years ago, Agile spotted a gap in the market for an industrial-grade, hydrostatic vehicle that could operate on any terrain whilst maintaining manoeuvrability, speed, robustness, value for money and a heavy load capacity.

Rotary Power cares the ‘hydraulic side of the moon’

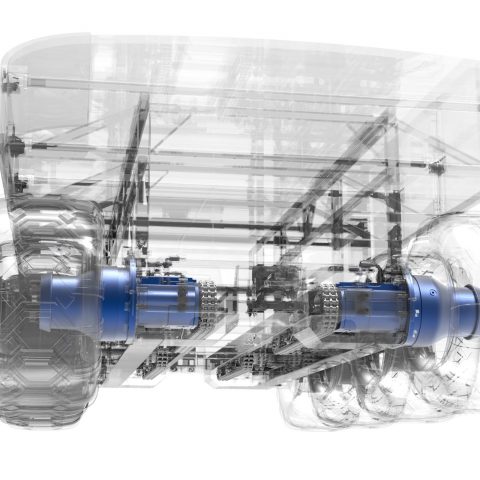

Previous multi-terrain vehicles have been notoriously expensive and have issues with durability. Other vehicles, such as tractors, have a tendency to struggle on more challenging terrains due to their mechanised drive system. Keen to work with British suppliers, Agile contacted North East based hydraulic motor manufacturer, Rotary Power. The challenge was to develop a hydraulic motor that could power each wheel independently, whilst driving additional wheels using an internal chain drive system. This would provide the vehicle with a compact, powerful drive system with an ultra-low centre of gravity. The solution, a bespoke motor with a unique through shaft that allows the motors to be attached to the vehicle’s chain drive system, as well as the wheel hub. The motor’s two-speed feature allows the vehicle to reach speeds of 40 km/h, whilst providing 4000Nm of torque and 96% efficiency level.

The Agile’s voice

Stuart Sowray, Chief Designer at Agile, said: “As a start-up, we were working to a really tight budget so it was important to get the design right first time. Laura, one of the Design Engineers at Rotary Power, took a lead on the detailed design work for the motors, which was particularly impressive since this was her first major engineering project. She has been fantastic, she’s really thrown herself into the challenge and it’s been brilliant to watch her develop as an engineer“.

“The willingness of Rotary Power to engage with a start-up like us on the technical challenge we presented has been really refreshing. This made a huge difference as made it easier for us to gain funding for our ideas. Their introduction to other manufacturers such as Related Fluid Power, enabled us to access expertise that would have otherwise been difficult to come by. What we’ve achieved collectively is really exciting and it’s been great to bring together innovative engineering companies to develop a ground-breaking product.”

For any terrain

The resulting eight wheeled vehicle provides an unparalleled solution that combines a fully sealed water-tight body with a 1.8 metre wide, three-way tippable load bed and two tonne capacity. The vehicle’s ultra-low ground pressure means it can function on any terrain without causing damage. The underlying hydraulic base can be reconfigured for a variety of applications including firefighting, agriculture, recreation, sport and forestry.

Laura Parnaby, Design Engineer at Rotary Power, said: “It has been a great learning experience collaborating with the customer on this project. I have had the opportunity to visit them at several locations to carryout data acquisition and witness the vehicle successfully operating in extremely challenging conditions. Seeing our motors performing in the field was so rewarding and gathering ‘real life’ application data was invaluable”.