Schaeffler for Energy Efficiency

Schaeffler turned its attention to energy efficiency in manufacturing at the Dortmud maintenance trade fair with the Power-Adapt system

When the word efficiency echoes from these desks, one tunes in to the frequencies of chamber fuel optimisation and thermodynamic efficiency. Schaeffler also has the declination of efficiency in the area of industrial maintenance in its ropes. Participants at the maintenance exhibition, which ends today in Dortmund, were able to experience this first-hand. The comprehensive range of products, services and solutions in the areas of energy and condition monitoring, assembly and lubrication.

Schaeffler and efficiency. A link that also runs through Power-Adapt

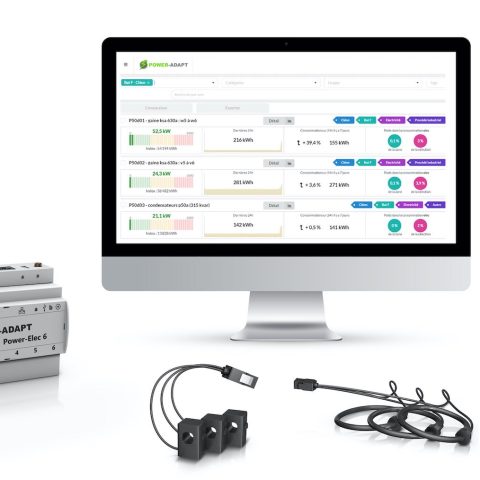

With its Power-Adapt energy monitoring solution, Schaeffler keeps a close eye on energy consumption, including electricity and other resources. Power-Adapt offers flexible application options: it can be integrated into new installations as well as seamlessly incorporated into existing energy management systems or combined with other solutions such as facility management systems. In addition to measuring electricity, gas, and water consumption, sensors can also track environmental variables such as temperature, humidity, and CO₂ concentration. By monitoring baseline loads and peak values, Power-Adapt generates notifications that enable swift responses to abnormal consumption patterns. Furthermore, the system aggregates data from multiple devices to analyze process and infrastructure efficiency. Ultimately, these tools help normalize energy consumption and prevent costly peaks—both in terms of CO₂ emissions and financial impact—particularly in a period of rising gas prices.

A practical example comes from Smurfit Westrock, a global leader in paper-based packaging. Headquartered in Dublin, the multinational has installed Power-Adapt in 20 facilities to monitor and analyze energy consumption. Schaeffler’s contribution to Smurfit Westrock’s energy efficiency has reportedly led to a 57% reduction in electricity consumption outside production hours. The company now plans to implement Power-Adapt in seven additional facilities in France in the near future.

Together with Siemens for AI

Schaffler collaborates on efficiency with Siemens in the field of artificial intelligence.

“Digitalization is one of Schaeffler’s key topics,” says Klaus Rosenfeld, CEO of Schaeffler. “The use of AI-based solutions is a decisive factor for making production processes more innovative, agile, and efficient. With Siemens, Schaeffler has a strong industrial partner at its side to accelerate the development and implementation of generative AI solutions in a targeted manner and to generate added value for its customers.”

Cedrik Neike, Member of the Managing Board of Siemens and CEO Digital Industries, added, “Siemens and Schaeffler are pioneers on the path to highly-automated and digital factories. With the ‘Siemens Industrial Copilot’, we are bringing the capabilities of generative AI to the Schaeffler shop floor,”