The role of Parker in the CE market (Part II)

Parker Hannifin has been developing a full range of products designed for the off-road sector. Last week we’ve published the very first part of our interview with Dennis C. Allen, Global Mobile Engineering & Business Development Manager at Parker Hannifin (here’s the post). The following is the second and last part of the interview, particularly […]

Parker Hannifin has been developing a full range of products designed for the off-road sector. Last week we’ve published the very first part of our interview with Dennis C. Allen, Global Mobile Engineering & Business Development Manager at Parker Hannifin (here’s the post). The following is the second and last part of the interview, particularly focused on the products, starting from pumps designed for mobile machines.

Parker pumps for mobile machines

As for pumps, what is the major requirement when designing a product thought for mobile machines? Compactness, power density, easy integration…

From Parker’s Hydraulic Pump and Power Systems (HPS) experience, the key requirements when designing a hydraulic pump for mobile applications are compactness, power density, high-speed and responsiveness.

HPS’ new P1M Series delivers higher speeds and efficiency that increases machine productivity, reduces costs, and extends pump life in a robust, compact envelope. In fact, the P1M Series increased an OEM’s construction equipment’s machine performance on the job resulting in fuel savings, lower emission levels and an improved machine response.

We know that Parker has been paying great attention on the matter of IoT. How difficult is it to explain the benefits of sensorization, smart fleet management and predictive maintenance to manufacturers and users in CE?

The specific value to fleet owners and managers is quite easy to explain. Condition monitoring and alerts, along with increased up time and lower maintenance costs, help fleet assets be managed most efficiently. Mobile equipment OEMs and their customers have immediate access to large and robust collections of data which can be acted upon quickly to improve functional efficiencies, operator wellness and productivity.

The complex mechanical, electronic and hydraulic systems used by mobile equipment and machinery, when supported by digital ecosystems, are ushering in a new era of mobile solution innovation. Today’s motion control enterprises are leading the way toward safer, cleaner, more efficient and more reliable mobile equipment overall as well as catalyzing innovation for the next generations of connected equipment.

Hybrid solutions. Parker is working on…

In your opinion, are hybrid actuation solutions the current and future standard also for off-road machinery? Could you tell us something more about the HAS 500 Series?

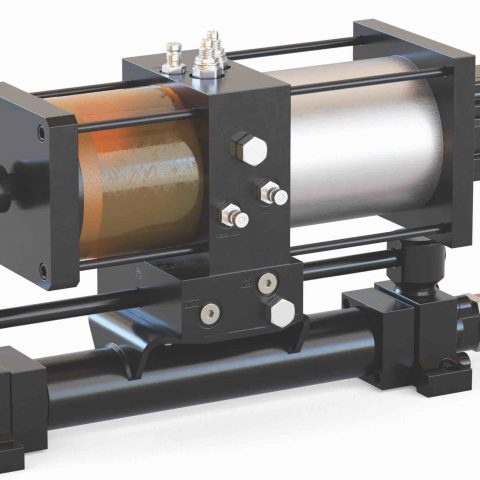

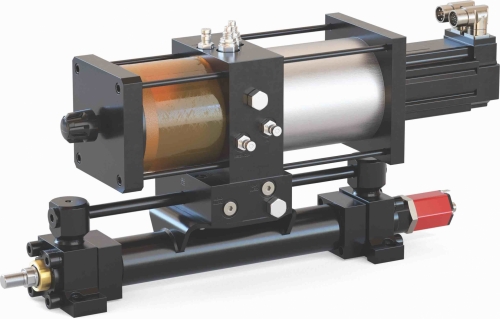

The HAS 500 is a hybrid actuation system that consolidates the entire hydraulic system into a single component integral to the actuation that hooks up to a local control point. This eliminates the centralized power unit with its electric motor, pump reservoir and related valving and removes the need for hoses and tubes connected to the actuator that are often found in traditional hydraulic systems, helping to simplify the design and lower the overall cost of a hydraulic system. The HAS 500 leverages electromechanical (EM) concepts such as using fluid transmission to move the actuator to turn a pump rather than rotating a screw. Since the actuator is hydraulic, it delivers three times the power density of the a comparably sized EM solution.

How is the market for hydraulic applications evolving, given the demands for decarbonisation and M&A, such as that between Danfoss and Eaton Hydraulics?

As we look to the future for hydraulic applications, there is no doubt that technology will play a major role in improving efficiencies and sustainability. Parker team members around the world innovate to develop custom solutions that lead to a better tomorrow: a smarter, safer and more sustainable tomorrow. And that means working closely with customers across many different industries to help solve their own unique challenges.