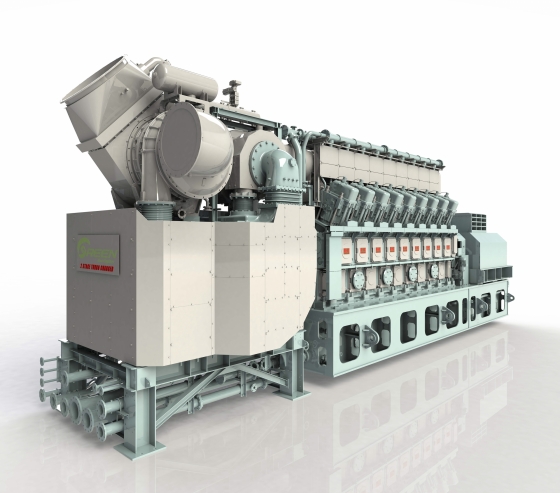

Two-stage Ecocharge turbocharging system for highest efficiency

Kawasaki Heavy Industries’ new type KG-18-T gas engine, equipped with PBST’s two-stage ‘Ecocharge’ turbocharging system has recorded the world’s highest class power generation efficiency of 51 percent with Japanese standard city gas. The KG-18-T’s Ecocharge solution consists of one PBST TCX23 and one PBST TCA66 turbochargers that have improved its power-generation efficiency by 1.5 percent […]

Kawasaki Heavy Industries’ new type KG-18-T gas engine, equipped with PBST’s two-stage ‘Ecocharge’ turbocharging system has recorded the world’s highest class power generation efficiency of 51 percent with Japanese standard city gas.

The KG-18-T’s Ecocharge solution consists of one PBST TCX23 and one PBST TCA66 turbochargers that have improved its power-generation efficiency by 1.5 percent compared to the previous generation of the engine, delivering a world-best class 51.0 percent in its output class. According to the engine manufacturer, both engine and turbochargers have passed a durability test and are now ready for serial production.

The principle of the Ecocharge turbocharging system

The Ecocharge principle optimally combines a low-pressure turbocharger – usually a TCT, TCA or TCR – with a high-pressure stage for which the newly developed TCX series was designed.

The increase in turbocharging efficiencies, in comparison to single-stage turbochargers, is mainly related to the intercooler – positioned between the low-pressure-stage and high-pressure-stage turbochargers – that significantly reduces the energy required to compress the intake air to high pressure. The resulting, higher efficiencies have an instantaneous impact on the engine by advantageously increasing the air pressure over the cylinder during the scavenging process.

Highest class efficiency in this output range

«Our new KG-18-T gas engine raises high expectations. This engine is the latest and most-efficient addition to our Kawasaki Green Gas Engine Series. The design is based on its previous models KG-18-V and KG- 18, which count more than 180 sold units since their introduction ten years ago. The newly developed two-stage turbocharging system improves power generation efficiency significantly resulting in the world’s highest class efficiency in this output range. Consequently, we are keen awaiting to continue this engine’s success story», commented Mr. Sakai, Senior Manager Four-stroke Engine Department and Head of Design Department at Kawasaki Heavy Industries.