Vanzetti Engineering: new cryogenic centrifugal pumps

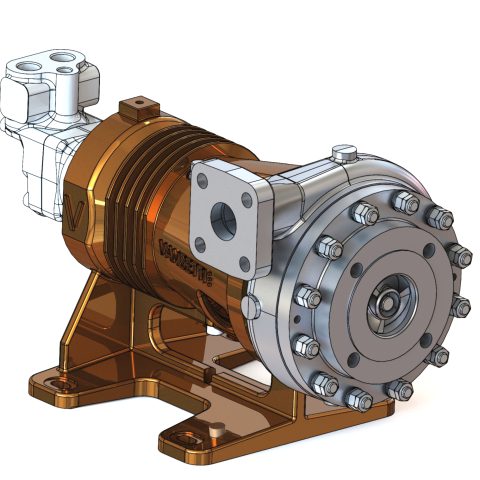

Vanzetti Engineering has developed the new HDM series to expand its range of cryogenic centrifugal pumps on board tanker trucks.

With the new HDM series, which joins the already existing HGM series, Vanzetti Engineering completes its range of on-board cryogenic centrifugal pumps. Thanks to this expansion of the range, Vanzetti Engineering is now able to meet any type of requirement for the loading and unloading of mobile tankers.

The cryogenic centrifugal pump on board a tanker truck has the function of transferring the LNG from the truck to the tank of the refueling station, allowing to compensate for the pressure differential existing between the tank being loaded and the tank of the heavy vehicle. The HDM (Hydraulic Direct Motor) series pumps, unlike those HGM (Hydraulic Gearbox Motor), have a direct connection hydraulic motor as they do not have a gearbox. This feature allows you to limit costs, without sacrificing performance. The new HDM pumps have a particularly robust structure and offer a maximum operating speed of 7500 rpm, with a maximum flow rate of 320 lpm (liters per minute).

This new type of pump, which includes the HDM 185 and HDM 200 models, offers important advantages: the low weight allows to maximize the payload and the particular compactness allows it to be installed even in limited spaces.

“The introduction of this new series allows Vanzetti Engineering to be even more competitive on the market, offering an additional type of cryogenic centrifugal pumps on board tanker trucks that transport LNG to refueling stations”, explains Luca Gazzera, LNG industrial & automotive sales manager at Vanzetti Engineering. “With the new HDM series we are also able to meet the needs of those who need a cost-effective solution, while maintaining the high level of performance and reliability that has always characterized all Vanzetti Engineering products.”

HDM pumps represent an ideal solution for: unloading road trailers, storage/iso-container (loading and unloading); process and backup operations in applications for the petrochemical industry; special applications with different head and flow rate according to customer needs.