VTA is now standard for MAN 51/60DF

MAN ES is now the first turbocharger manufacturer to make VTA standard for large-bore, four-stroke engines MAN Energy Solutions has announced that VTA (Variable Turbine Area) is now standard on TCA turbochargers for its MAN 51/60 engine type. Marking the first time that this technology has been approved as standard for a large-bore MAN four-stroke […]

MAN ES is now the first turbocharger manufacturer to make VTA standard for large-bore, four-stroke engines

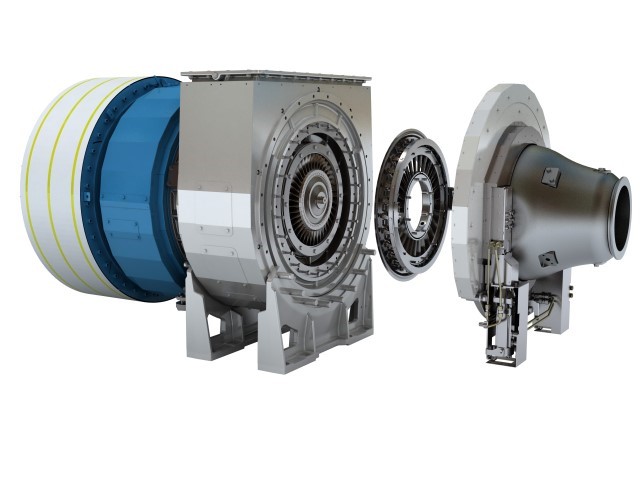

MAN Energy Solutions has announced that VTA (Variable Turbine Area) is now standard on TCA turbochargers for its MAN 51/60 engine type. Marking the first time that this technology has been approved as standard for a large-bore MAN four-stroke engine. In fact, MAN is the only turbocharger manufacturer to offer axial turbochargers with VTA as standard for any large-bore, four-stroke engines.

Stefan Terbeck, Project Manager for the MAN 51/60 engine series at MAN Energy Solutions, said: «High-tech solutions are necessary to meet the market’s demanding requirements and, with this announcement, we have really delivered. VTA turbochargers are becoming more and more important, especially when it comes to gas engines. VTA has already been applied from our licensee, Kawasaki Heavy Industries, who has reported excellent performance and high reliability on their engines. Furthermore, the concept is even now employed commonly in the significant formaldehyde-manufacturing segment».

MAN Energy Solutions data talk about more than 380 references of turbochargers sold with VTA technology, and that it is approved for its TCA turbocharger sizes TCA55 to TCA88, both for marine and power applications. Terbeck added: «We collected more than seven years of operational experience before approving this technology as standard. As a result, our 51/60DF engine is getting a proven, field-tested product».

DUAL-FUEL OPERATION FOR A DREDGER BY MAN 35/44DF

The role of this technology

Under the VTA concept, the volume of charge air can be precisely matched to the quantity of injected fuel at all points in an engine’s load and speed range. This has several benefits, including: fuel savings, improved dynamic performance, smart control management that also means engine adapts itself automatically to get to best possible operating point, range extension that includes elevated ambient temperature without de-rating and peaking balance to handle load fluctuations.

MAN ES reported that the typical payback period for VTA on its engines will be one-and-a-half to two years. Its next step is to make the technology standard for MAN 51/60G engine type. MAN PrimeServ Academy has already increased the VTA training portofolio, due to its rising importance. In particular, a VTA-VacSeal four-stroke course was introduced in September 2018.