ZF: CeTrax lite begins series production

CeTrax lite electric central drive is rolling off ZF’s assembly line in Friedrichshafen, Germany. It is a tailor-made solution for light-duty commercial vehicles for emission-free urban and inner-city transportation world-wide. The first applications will take to the road with Isuzu in its new ELF EV.

ZF ’s Commercial Vehicle Solutions (CVS) division has announced that its new CeTrax lite electric central drive has entered series production. Using synergies from ZF’s development and production of passenger car drives, the new driveline is adapted to use in light commercial vehicles. Designed as a highly integrated electric drive, CeTrax lite provides significant advantages for manufacturers worldwide, particularly supporting emission-free urban and “last mile” deliveries. The technology has already received orders from Asia and the Americas. The production started in Friedrichshafen, using the Group’s competence coming from passenger car technology.

“As an electric central drive, CeTrax lite allows our customers to electrify their existing vehicle platforms. This proves our technical approach and further demonstrates the trust customers are placing in our electric solutions,” said Winfried Gründler, Head of Product Line for Driveline Systems with ZF’s Commercial Vehicle Solutions division.

“Designed for silent, emission-free inner-city and ‘last mile’ freight delivery, CeTrax lite provides leading levels of performance and efficiency. As such it represents an important new milestone in our ‘Next Generation Mobility’ strategy and reinforces our commitment to decarbonization of the industry,” added Gründler.

CeTrax lite: a highly integrated eMobility solution from ZF

Providing a smart “turn-key” solution to support the needs of light-duty commercial vehicles, ZF’s CeTrax lite technology supports the architectures of conventionally fueled vehicles as well as manufacturers’ electrification strategies. Leveraging in-house developed components and wider eMobility system synergies including sharing test benches in Friedrichshafen.

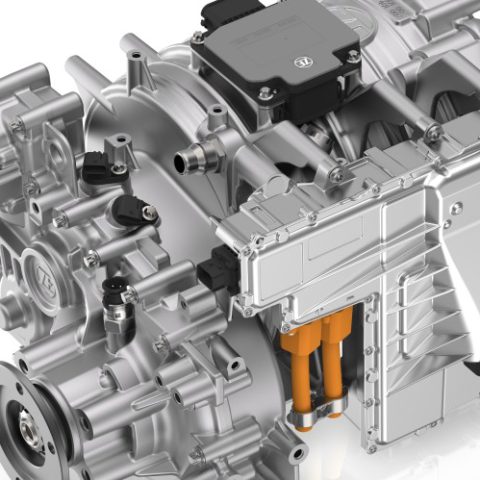

Designed for light commercial vehicles up to 7.5 tons, CeTrax lite has a peak performance of 150 kW and a torque of 1,500 Nm. The optimized compact design of CeTrax lite helps maximize space for electric components and batteries. The module is a fully integrated system, housing the electric motor as well as a 1-speed transmission stage and power electronics. In addition to its enhanced flexibility, the system offers a light-weight design at around 120 kg.

One of the first customers, the Japanese manufacturer Isuzu will install the drive in its new ELF EV.