ZF: the future of forestry

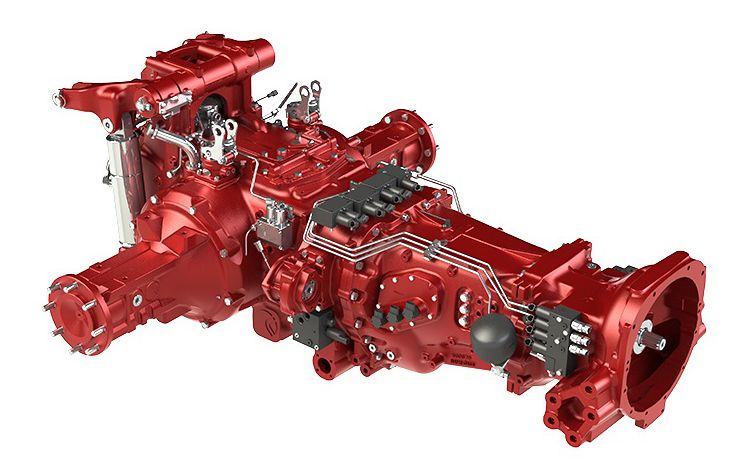

At this year´s ELMIA Wood in Jönköping, Sweden, ZF is presenting future-oriented drive solutions for forestry applications: the cPOWER CVT technology, for higher performance and less fuel consumption, and the Redulus Gearboxes for large shredder power units.

At this year´s ELMIA Wood in Jönköping, Sweden, ZF is presenting future-oriented drive solutions for forestry applications: the cPower CVT technology (the first version was released in 2018), for higher performance and less fuel consumption, and the Redulus Gearboxes for large shredder power units.

With high loads, continuously variable speeds, and therefore comfortable manoeuvring – the ZF cPower power-split CVT technology combines these characteristics with improved fuel consumption of up to 30 percent. Being in series production for forwarders since more than two years now, the fully power-split, continuously variable transmission offers significant consumption benefits and productivity increases for the vehicle owner. It operates at low engine speeds, thus increasing efficiency and driver comfort in forestry equipment like forwarders and skidders even more. The gain in tractive power through the innovative transmission system is particularly beneficial for the user when driving on challenging terrain types, like steep slopes or soft ground.

The continuously variable transmissions clearly demonstrate their benefits in all ranges of the typical forestry machinery operating cycle, i.e., during transporting or loading. In this process, the percentage of hydrostatic power is kept low whereby; an optimal degree of efficiency can be achieved.

Already in the start-up process there is a power split between mechanical and hydrostatic drive. The share of the mechanical power increases with the vehicle speed up to 100%. Even in very short loading cycles, the utility of the CVT technology becomes noticeable in reduced fuel consumption.

The application of an elaborate hydraulic transmission-control unit and transmission-integrated on-board electronic unit optimally completes driving functions. The application of these units is done with reference to sensitivity and driving comfort and realizes an aligned power management.