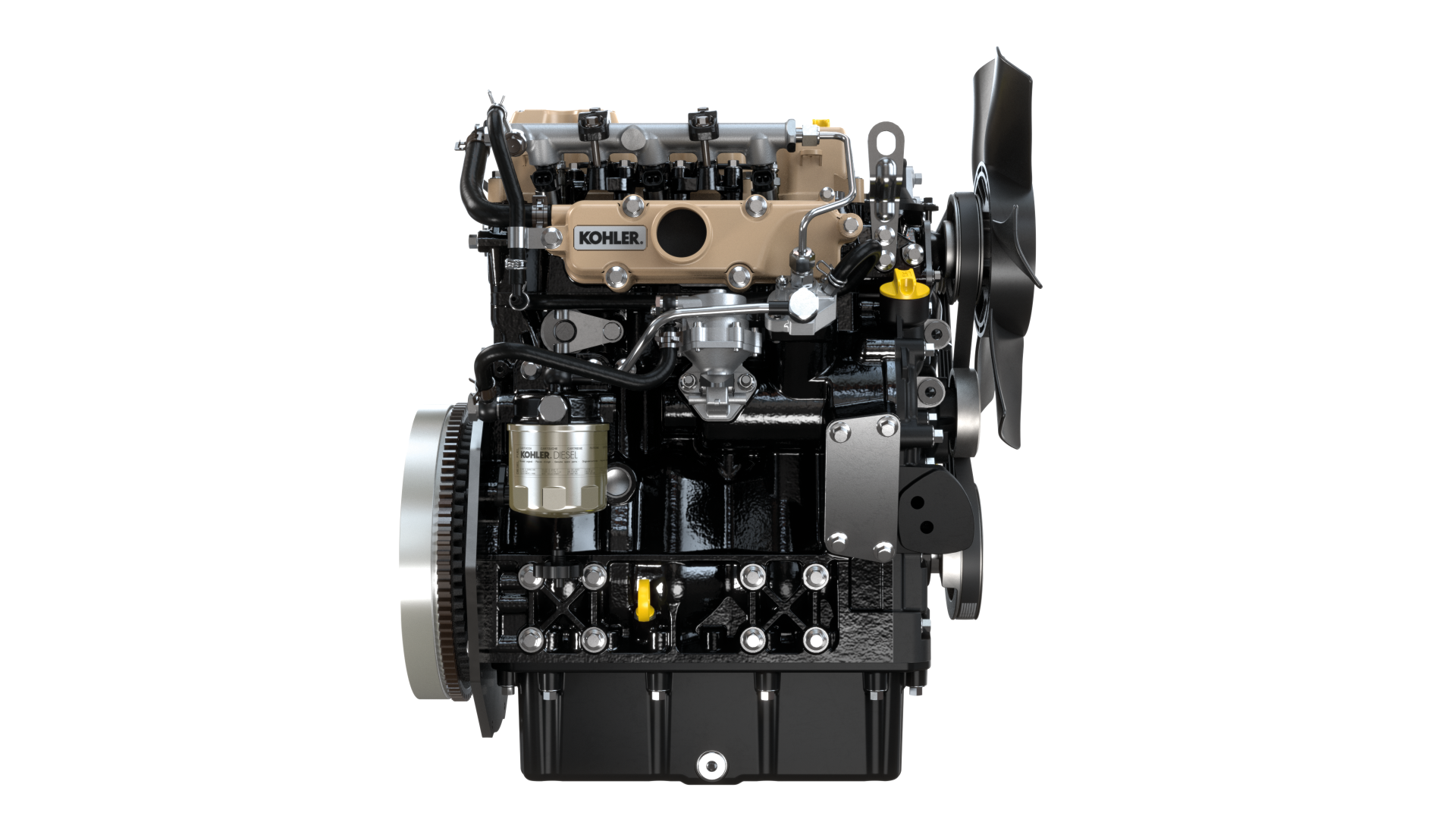

[Diesel of the Year] Kohler KSD 1403TCA: clean, efficient ICE

Mauro Mancuso, Senior Product Manager, Diesel Engines, of Kohler comforts us on the relevance of the Diesel cycle. The KSD has been conceived according to the needs of the OEMs, guaranteeing an entirely “plug & play” formula: the engine is at the service of the first to the last instant of service.

Kohler ’s KSD is Diesel of the Year 2022. Where and how the design of an endothermic with a displacement so exposed to “electric” disturbances begins. We hear directly from Mauro Mancuso, Senior Product Manager – Diesel Engines Marketing.

“In recent years, the need to reduce emissions to address environmental issues has not only affected the automotive world but also the off-highway. Significant changes are expected in the next decade especially in emission regulations, and Kohler is certainly ready to address them and invest in clean energy sources. However, we must not forget that the different OEMs we interface with have different needs. Every application and every industry have many variables to consider, and Kohler has always aimed to go against every need, studying solutions for everyone. That is why we have developed the new Kohler KSD family, which promises to be suitable for all geographical areas, compliant with all regulations worldwide, and compatible with all types of machines. It is the result of a totally market-oriented approach and built together with customers, not for customers. We involved them from the very beginning, listening to their needs, and studying a variety of tailor-made solutions that made it possible to optimize the KSD for multiple different applications”.

I am a small manufacturer of skid steer loaders and professional lawn mowers. My customers work mainly in construction sites and urban gardens, so I would like to rely on a full electric solution. How do you convince me to use the Kohler KSD?

Whatever the industry, the demands of OEMs are always the same: more power, less fuel consumption, better exhaust emissions, engine durability – the latter also connected to a low total cost of ownership. With the KSD, we have developed an engine that can meet all these needs but choosing a compact design. The Kohler KSD offers efficiency and work consistency, has a low total cost of ownership, long service intervals, and provides for extended engine life. In the case of professional lawn mowers, the operator mainly needs power for cutting, and therefore more torque. The KSD has exceptional low-speed torque, which allows the machine to be operated at low rpm to save fuel, while still maintaining very high performance. At the same time, comfort is not left aside: noise and vibration are minimized thanks to NVH analysis. Certainly, electric applications are making important strides and are a special watch. With respect to these, the KSD offers continuity of work, i.e. very long intervals of machine operation, which can be translated into efficient and consistent duty cycles without battery recharging interruptions.

What are the benefits of the work you have done to reduce CO2 emissions and fuel consumption?

By reducing fuel consumption, we not only reduce the expense to the user, but also reduce emissions, going to hit all the regulations in different parts of the world. In fact, emission regulations are constantly changing, and we adapt by meeting our customer needs. Kohler engines comply with the most stringent off-highway regulations, which now correspond to EU Stage V, US Tier 4 Final and, at the end of this year, also China Stage IV.

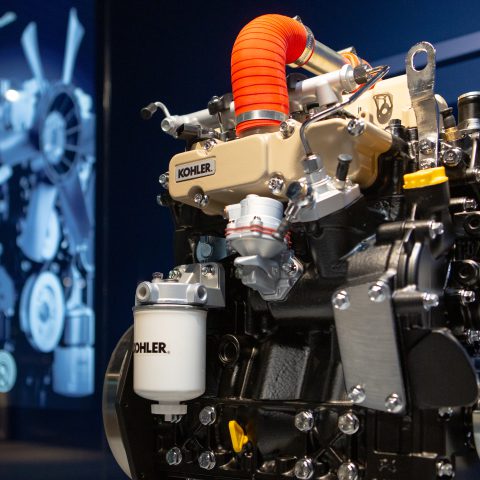

An engine so efficient that it breaks free from the dimensional and functional restrictions of EGR and after-treatment systems. An engine that looks to the future while drawing inspiration from the past. It sounds like a paradox but it is the picture of the Kohler KSD, isn’t it?

Engine efficiency is the result of the design, both the engine itself and the production process, created from a blank sheet of paper, using the best existing technologies so that efficiency and performance are maintained at the highest quality standards. All this is supported by the innovative electronic system that we can call a “back to the future” with a cinematic term.