BorgWarner, from Waste Heat to Electrical Energy

BorgWarner’s Organic Rankine Cycle BorgWarner’s Organic Rankine Cycle (ORC) waste heat recovery system is the new technology for the commercial vehicle sector. In conventional applications, almost 50 percent of the engine’s fuel energy is rejected to the environment as heat. ORC waste heat recovery presents one of the most effective solutions to this challenge. BORGWARNER […]

BorgWarner’s Organic Rankine Cycle

BorgWarner’s Organic Rankine Cycle (ORC) waste heat recovery system is the new technology for the commercial vehicle sector. In conventional applications, almost 50 percent of the engine’s fuel energy is rejected to the environment as heat. ORC waste heat recovery presents one of the most effective solutions to this challenge.

BORGWARNER AS MARCO POLO GOES STRAIGHT TO CHINA

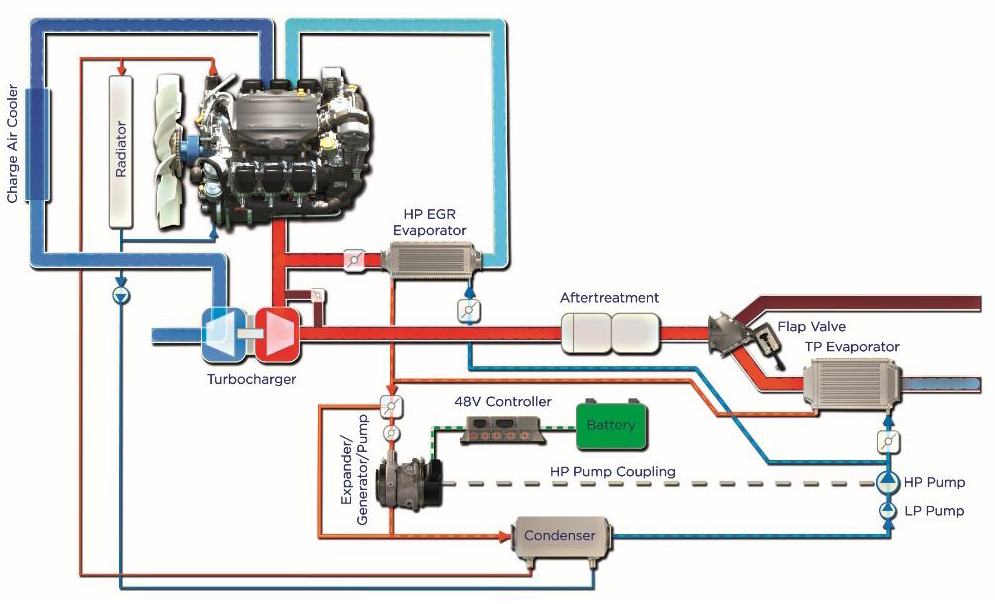

BorgWarner produces and develops a complete system, consisting of tailpipe and EGR evaporators, an exhaust flap bypass valve, a turbine expander as well as power electronics and a condenser. Thus, the company provides its customers with an advanced solution that reduces CO2 emissions, improves fuel economy by 3 to 5 percent and supports mild hybrid commercial vehicles.

About this project, Joe Fadool, President and General Manager of BorgWarner Emissions & Thermal Systems, said: «At BorgWarner, we constantly aim to drive the latest advancements in efficient mobility, by converting wasted exhaust heat into usable electrical energy, we support our customers and protect the environment at the same time».

How does it operate?

BorgWarner’s ORC waste heat recovery system generates electrical energy by converting energy from the fuel that would be typically wasted as heat. The system takes advantage of the phase change characteristics of fluids in a similar way to air conditioning or refrigeration systems. This cycle can be divided into four steps.

First, the cool working fluid from the condenser is pumped to high pressure. Second, the waste heat from the engine heats the working fluid to a superheated vapor, which in turn drives the turbine expander and generates electrical power. Third, the low-pressure vapor is cooled back to a liquid state by the condenser, and fourth, the process repeats itself.

BorgWarner’s evaporators enable improved balance between durability and high performance. The exhaust bypass valve provides a valuable method for controlling the amount of heat entering the waste heat recovery system from the tailpipe exhaust system. The company’s exhaust bypass valve provides a proportional flow control of the exhaust and ensures low backpressure to maximize engine performance.

MORE ON EMISSION REDUCTION: CEMA AND CECE

About BorgWarner

BorgWarner is a global product leader in clean and efficient technology solutions for combustion, hybrid and electric vehicles. With manufacturing and technical facilities in 66 locations in 18 countries, the company employs approximately 29,000 people worldwide. The company reached $9.8 billion in sales at the end of 2017.