EGR and MAN, a New Step Forward

New EGR Technology by MAN EGR strikes back. In accordance with the principles of the German school (thermal balance and TCO reduction, by the restraint of consumption of AdBlue), MAN takes a step forward in terms of ERG in the OEM context. MAN Energy Solutions has launched its new EGR (Exhaust Gas Recirculation) electrical turbo […]

New EGR Technology by MAN

EGR strikes back. In accordance with the principles of the German school (thermal balance and TCO reduction, by the restraint of consumption of AdBlue), MAN takes a step forward in terms of ERG in the OEM context.

MAN Energy Solutions has launched its new EGR (Exhaust Gas Recirculation) electrical turbo blower, designated ETB40, at a ceremony in Shanghai attended by some 120 industry guests and hosted by its two-stroke licensee, CSSC-MES Diesel Co. Ltd (CMD).

Simultaneously, CMD announced that it has placed the first order for the new blower in connection with the construction of several MAN B&W two-stroke 7G60ME-C9.5 main engines for newbuilding vessels. Individual ETB40 units will be installed aboard each vessel as part of their main-engines’ integrated EGR system.

Ralph Klaunig, Vice President and Head of Turbocharger and Exhaust Gas Systems Sales, MAN Energy Solutions, said: «Our development of the ETB series is a strategic decision and a significant addition to our existing, proven EGR technology that will play an important role in maintaining IMO Tier III emission standards. This will enable customers to achieve sustainable value creation in the transition towards a carbon-neutral future. In taking this step, we are making use of our in-house turbocharger technology that features a significantly higher thermodynamic efficiency than previous designs».

MAN IMO TIER III SOLUTIONS. HERE WE ARE!

About the MAN ETB

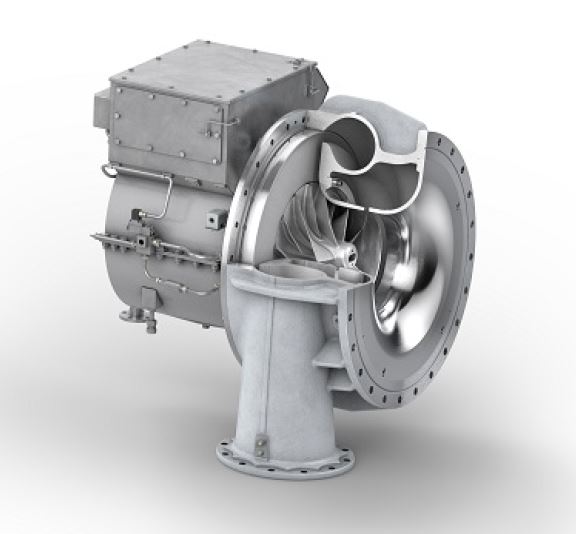

Specifically designed for EGR systems, the MAN ETB’s active control plays an important role in enabling these systems to reach IMO Tier III emission standards.

The blower is a core component of MAN Energy Solutions’ high-pressure EGR system that raises the exhaust-gas pressure in order to overcome the pressure difference exhaust gas and scavenging air receiver. The desired EGR operating conditions are achieved by using a high-speed electric motor, directly coupled to the compressor wheel and speed controlled by a frequency converter.

The MAN ETB features a highly-efficient blower wheel, optimised for the low-pressure ratios found in a two-stroke diesel engine and whose materials are designed to withstand corrosive agents. High blower availability (even during continuous operation) and variable-speed operation ensure IMO Tier III compliance in emission-controlled areas (ECAs), and potentially also in IMO TIER II mode with the new Eco EGR feature (officially acknowledged by DNV GL).

Since May 2015, 2 × ETB18 prototypes have run successfully on an 82,000-dwt bulk carrier equipped with an MAN B&W 6S60ME-C 8.2 Tier III engine. The ETB40 pased its FAT (Factory Acceptance Test) on October 17th.

MAN’s EGR System

As an alternative to the SCR method within MAN Energy Solutions’ Tier III programme, the Exhaust Gas Recirculation method is regarded as a very efficient means by which to reduce NOx in combustion engines.

As such, the MAN ETB EGR-blower is suitable for high-pressure EGR engines of all fuel types and in all application ranges. In contrast with SCR systems, Exhaust Gas Recirculation systems are integrated with the engine and of a significantly smaller size.