Volvo Penta Stage V

Volvo Penta Stage V. It may seem out of place, or out of time, to talk about Stage V just now that the EU moratorium has become official. Yet at Volvo Penta, where the wait for the Big Bang of electrification, scheduled for 2021, hasn’t waned, attention to reducing exhaust emissions is also, and above all, […]

Volvo Penta Stage V. It may seem out of place, or out of time, to talk about Stage V just now that the EU moratorium has become official. Yet at Volvo Penta, where the wait for the Big Bang of electrification, scheduled for 2021, hasn’t waned, attention to reducing exhaust emissions is also, and above all, focused on the endothermic engine. This is what they tell us from Götebörg.

Volvo Penta Stage V: Five ways to reach the goal

Stage V emission legislation is the most stringent regulation to date. As well as reducing emissions, Volvo Penta’s powerful Stage V engine range for off-road applications delivers improved productivity, uptime and total cost of ownership. Here are five ways they can help you to make your operation a success…

Stage V emission legislation requires off-road engines above 560 kW to have a diesel particulate filter (DPF) which captures and stores soot. The soot needs to be burned off to regenerate the DPF and this is normally done while the machine is at a standstill, known as active regeneration. However, Volvo Penta has a ‘Regeneration Zero’ vision which means they’ve minimized the need for active regeneration as much as possible, reducing downtime and keeping customers’ machines operational and profitable. Through an optimized engine and exhaust aftertreatment system that work seamlessly together, the Volvo Penta solution increases uptime by maximizing the use of passive regeneration. Here, the soot accumulated in the DPF is burned off during normal machine operation, without the need for frequent active standstill regeneration.

A reduction of up 5% in fuel consumption

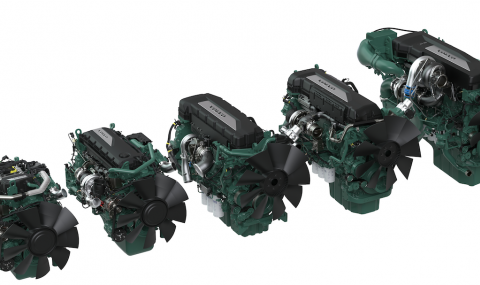

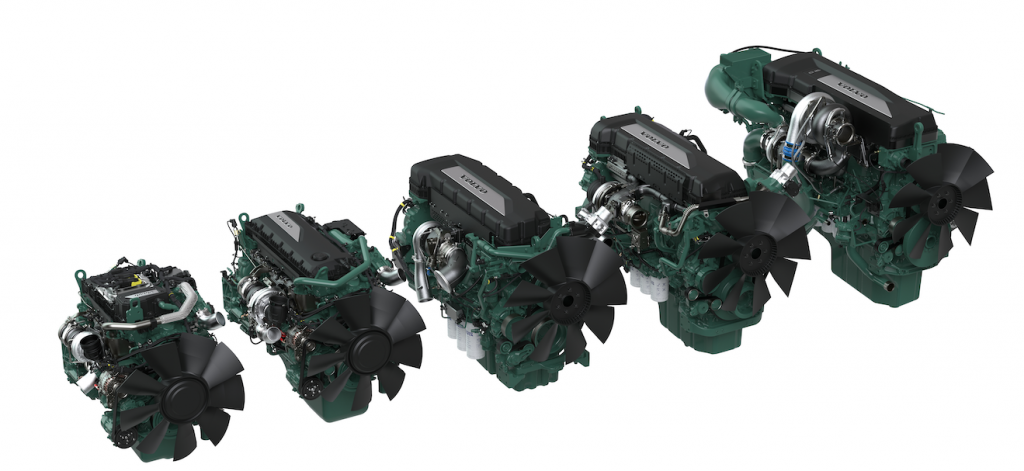

The Volvo Penta Stage V diesel engine range delivers a reduction of up to 5% in fuel consumption, compared to Stage IV, contributing to an extremely attractive total cost of ownership. Lower fuel consumption also means that less CO2emissions are released into the atmosphere, helping to reduce greenhouse gases and enabling customers to reach their sustainability goals. All Volvo Penta’s Stage V engines are designed to fit into the same footprint as the model they replace, meaning that customers don’t have to redesign their machines to accommodate new engines. With Volvo Penta’s two-box aftertreatment system, customers benefit from simple, flexible installation. The Volvo Penta off-road diesel engines are tailor-made for applications in different segments and environments, such as forestry, agriculture, mining, material handling and construction projects. There are five base engines in the Stage V line up – D5, D8, D11, D13 and D16 – offering power from 105-585 kW (143-796 hp). When combined with multiple hardware options, the engine architecture can be specifically engineered to meet the needs of a wide range of applications.

To boost the reliability and uptime of its Stage V engine range, Volvo Penta has improved predictive maintenance and lengthened service intervals. For example, oil change service intervals have now doubled from 500 to 1,000 hours.